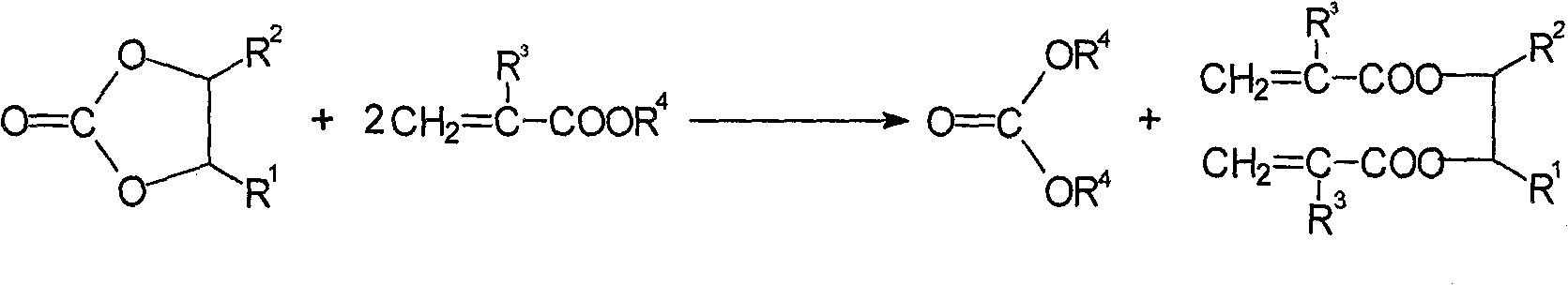

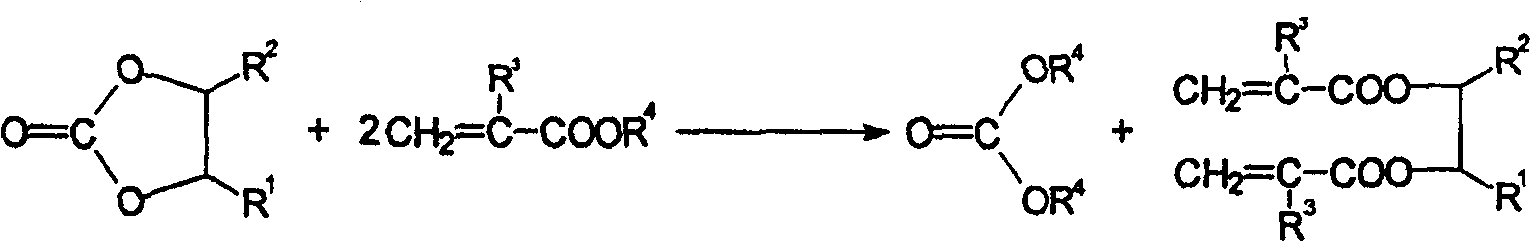

Method for simultaneously synthesizing dialkyl carbonate and acrylic acid analog aliphatic diol diester

A technology of dialkyl carbonate and aliphatic diol, which is applied to the preparation of organic carbonates, chemical instruments and methods, and carboxylate preparations, and can solve problems such as low added value, increased production costs, and difficulties in product separation and purification. Achieve the effect of increased product purity, high conversion rate, and improved atom economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The transesterification reaction of the present invention is carried out in a stainless steel reactor equipped with a thermocouple, an agitator and a distillation column, and the distillation column is provided with a condensation reflux head.

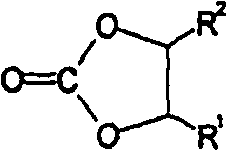

[0030] With ethylene carbonate (compound as shown in general formula I, in the formula R 1 and R 2 Both are H) and methyl methacrylate (as the compound shown in general formula II, where R 3 and R 4 Both CH 3 ) into the reactor at a molar ratio of 1:4, and then add the catalyst LiOCH which accounts for 3wt% of the total weight of the carbonic acid ester compound and the acrylic acid alkyl ester compound 2 CH 3 , and accounting for 0.5wt% of the polymerization inhibitor three (2,2,6,6-tetramethylpiperidinol nitroxide free radical) phosphite, the above mixture was reacted at 150°C for 9h, while reacting, it was distilled Dimethyl carbonate is separated at any time; after the reaction is completed, a mixture of dimethyl carbon...

Embodiment 2~8

[0033] According to the method of Example 1, transesterification reactions under different conditions were carried out, and the reaction conditions and results are listed in Table 1 and Table 2 respectively.

[0034] Table 1, transesterification reaction conditions

[0035]

[0036] In the table, a represents three (2,2,6,6-tetramethylpiperidinol nitroxide radicals) phosphite, b represents 2,2,6,6-tetramethylpiperidinol nitroxide radicals .

[0037] Table 2, transesterification reaction results

[0038]

[0039] As can be seen from the results in Table 2, the transesterification reaction carried out by the method provided by the invention has a high conversion rate of the raw material and good selectivity of the product.

[0040] Embodiment 9 and 10 and comparative example 1~3, use different polymerization inhibitors to carry out transesterification reaction

[0041] Use different polymerization inhibitors, carry out transesterification reaction by the method for embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com