A kind of polyurethane foam insole and preparation method thereof

A polyurethane and insole technology, which is applied in insoles, footwear, clothing, etc., can solve the problems of poor elongation of insoles, insole support performance and resilience performance can not be satisfied at the same time, easy to tear and other problems, to improve the rebound rate , Excellent tensile strength performance, and the effect of uniform dispersion of micropore diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

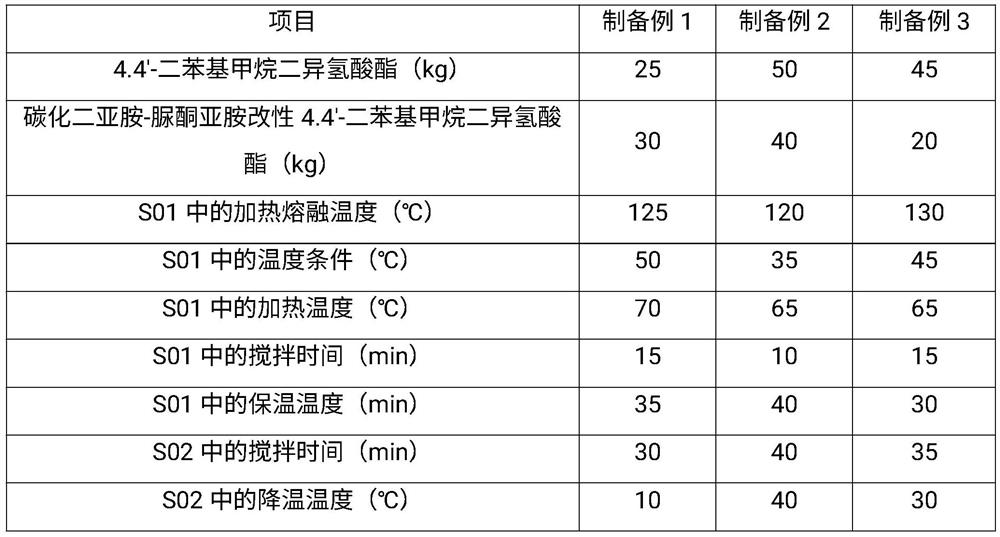

preparation example 1-3

[0054] A polyether-modified diphenylmethane diisocyanate is prepared by the following steps:

[0055]S01. Heat and melt 4.4'-diphenylmethane diisohydrogen ester at the temperature shown in Table 2, and then control the temperature to be below 50°C and pump the melted 4.4'-diphenylmethane diisohydrogen ester into The reaction kettle was added with polyether polyol under the temperature conditions shown in Table 2, heated to the temperature shown in Table 2, and the stirring time was shown in Table 2, followed by insulation, and the insulation time was shown in Table 2, and the reaction obtained -NCO base A prepolymer with a group content of 15%-25%, wherein the molecular weight of the polyether polyol C is 5000, the functionality is 3, and the hydroxyl value is 34 mgKOH / g;

[0056] S02. Mix the prepolymer with carbodiimide-uretonimide modified 4.4'-diphenylmethane diisocyanate, and the stirring time is as shown in Table 2, that is, the content of -NCO group is 20% -25% polyeth...

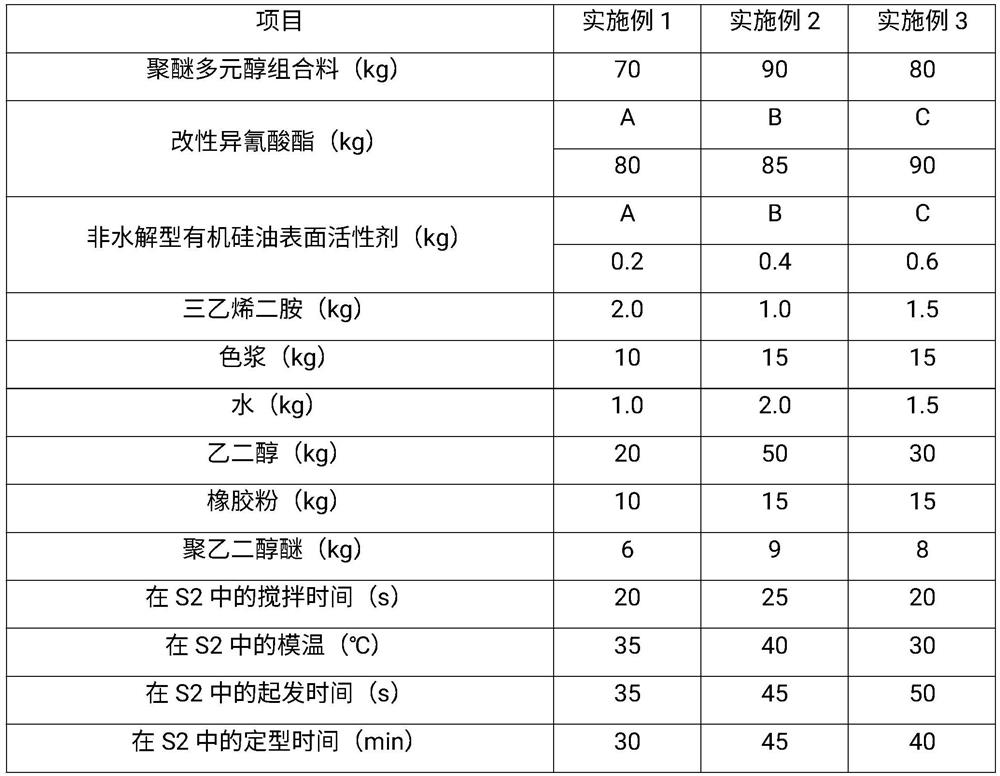

Embodiment 1-3

[0061] A polyurethane foam insole is prepared by the following steps:

[0062] S1. Weigh the required polyether polyol A, polyether polyol B and polyether polyol C and mix them into a polyether polyol composition material in a mass ratio of 5:1:4. Add color paste, triethylenediamine, rubber powder, polyethylene glycol ether and non-hydrolyzable silicone oil surfactant to the alcohol composition while stirring, and stir evenly to obtain a premix;

[0063] S2. Add the weighed modified isocyanate to the premix, stir at a rate of 500 rpm / s, the stirring time is shown in Table 3, and then inject into the mold. The mold temperature conditions are shown in Table 3, and the start-up time is shown in Table 3. As shown in Table 3, the mold is closed after 120s of milky whiteness, and the mold setting time is shown in Table 3, and then the molded insole is taken out, and the material can be cut after 24 hours of heat dissipation to obtain a polyurethane foam insole;

[0064] Among them,...

Embodiment 4

[0069] A polyurethane foam insole, the difference from Example 3 is that in step S1, 15kg of PU powder, PU powder and color paste, triethylenediamine, rubber powder, polyethylene glycol and non-hydrolyzable organic The silicone oil surfactant was added simultaneously.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com