Compact long-path layered scavenging structure cylinder body

A long-path, compact technology, used in cylinders, cylinder heads, engine components, etc., to solve problems such as reduced scavenging quality, insufficient pure air storage, and low safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

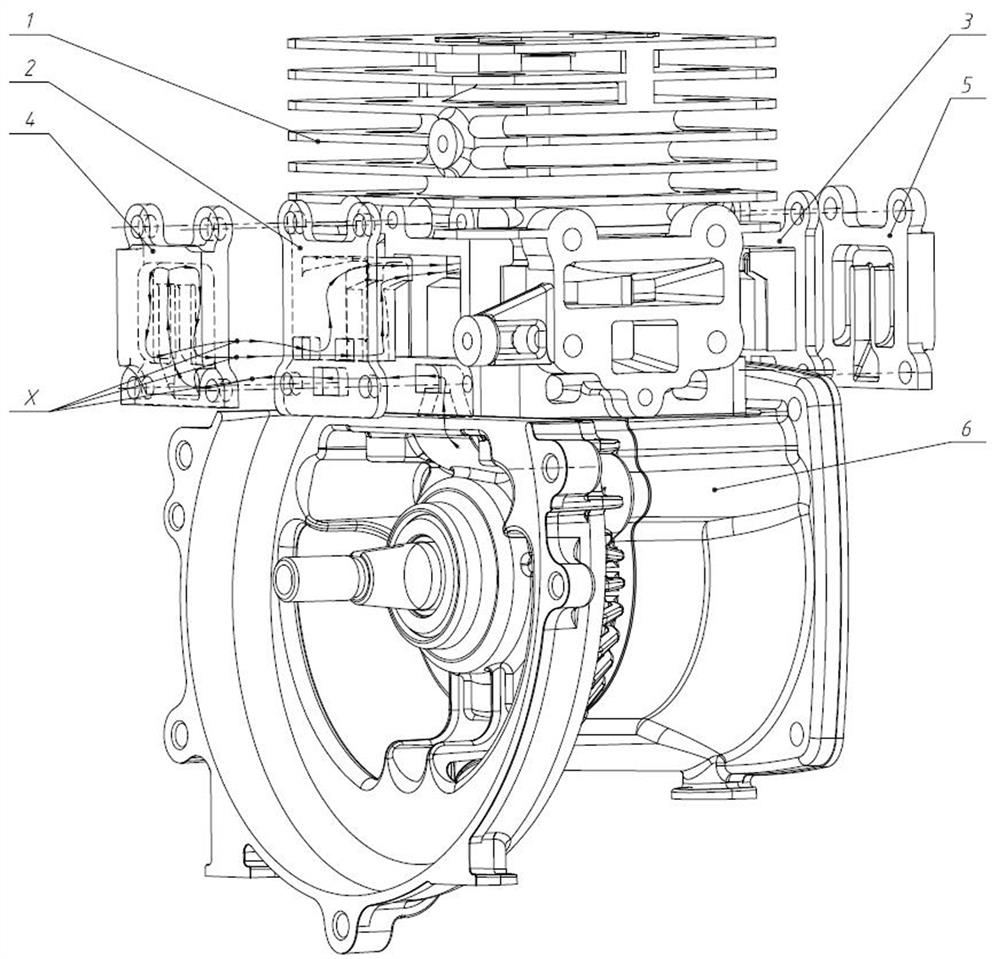

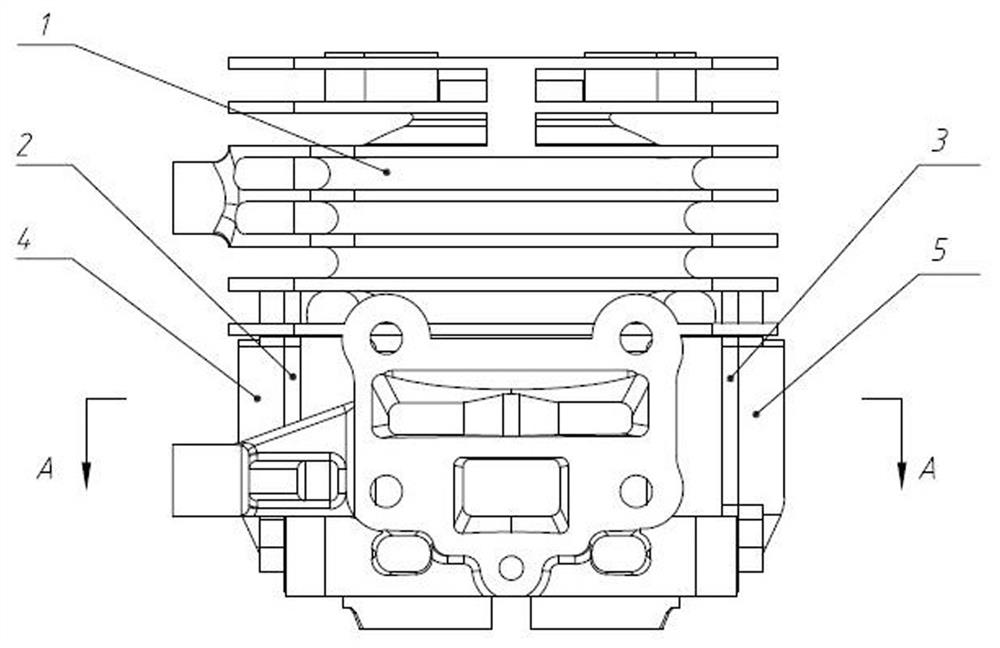

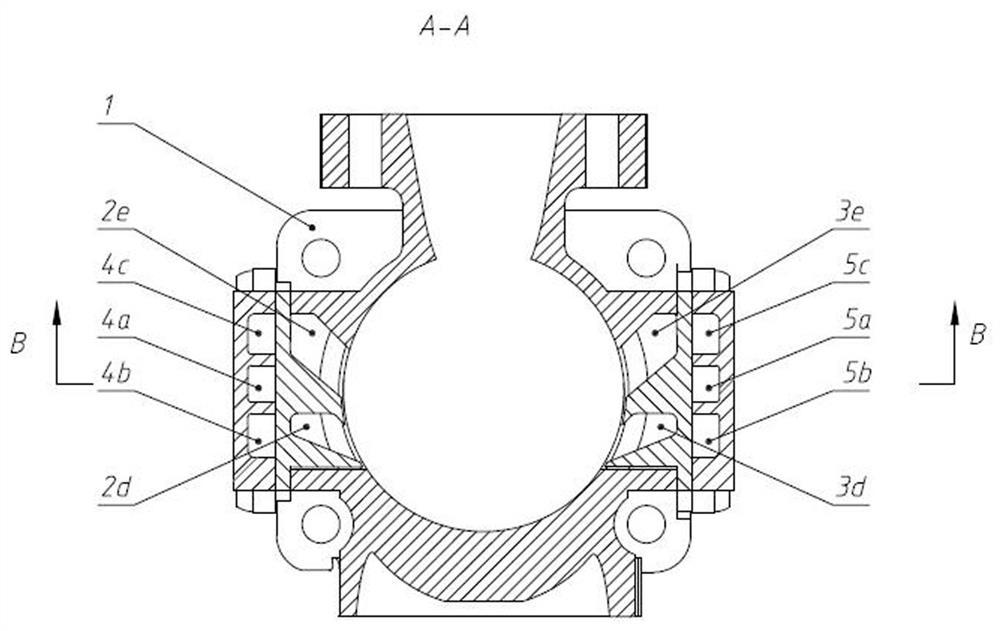

[0013] Such as figure 2 As shown, a compact long-path layered scavenging structure cylinder block includes a cylinder block 1 , a left middle side cover 2 , a right middle side cover 3 , a left outer side cover 4 , and a right outer side cover 5 .

[0014] Such as Figure 4 As shown, during the operation of the gasoline engine, when the piston 7 goes down, the compressed mixture x in the crankcase 6 passes through the cylinder scavenging passages 1a, 1b connected with the crankcase and the main side cover of the middle side respectively under positive pressure. The scavenging air ports 2a, 3a first enter into the main scavenging air passages 4a, 5a of the outer side cover. Such as Figure 5 , Image 6 As shown, the mixed gas x in the main scavenging air passages 4a, 5a of the outer side cover is detoured and shunted at the top end of the main scavenging air passages 4a, 5a, respectively entering the auxiliary scavenging air passages 4b, 4c and 5b, 5c, and then enter into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com