Flexible passive pressure sensor, preparation method and wearable touch sensor

A pressure sensor and flexible technology, applied in the fields of wearable tactile sensors, preparation methods, and flexible passive pressure sensors, can solve the problems of incomplete solution of dispersion and lack of piezoelectric characteristics, so as to improve performance and energy harvesting, Increase the dielectric constant and piezoelectric coefficient, and the effect of simple device process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

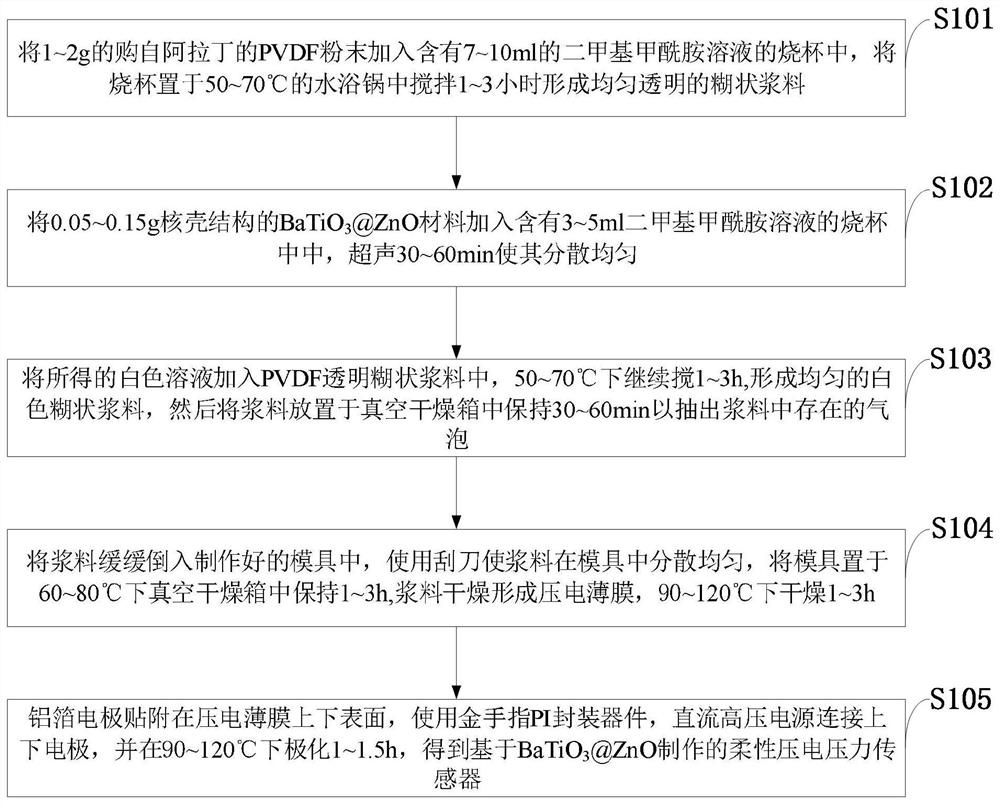

[0046] Such as figure 1 As shown, the preparation method of the flexible passive pressure sensor provided by the invention comprises the following steps:

[0047] S101: Add 1-2g of PVDF powder purchased from Aladdin into a beaker containing 7-10ml of dimethylformamide solution, place the beaker in a water bath at 50-70°C and stir for 1-3 hours to form a uniform and transparent paste slurry;

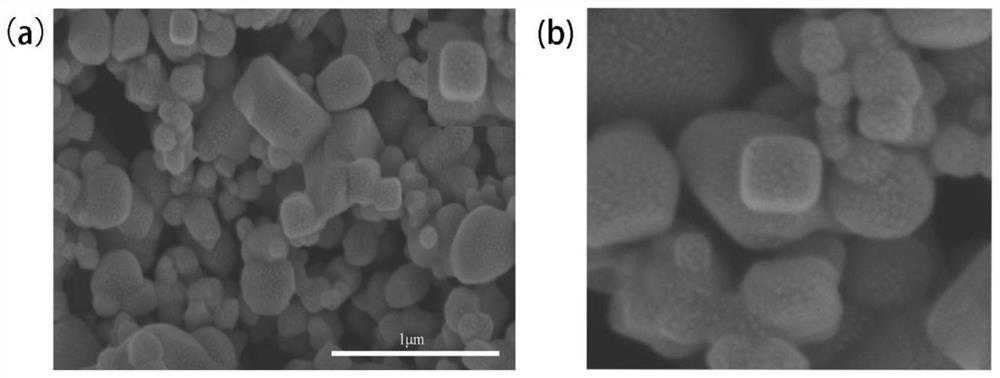

[0048] S102: Add 0.05 to 0.15 g of BaTiO with a core-shell structure 3 Add the @ZnO material into a beaker containing 3-5ml of dimethylformamide solution, and ultrasonically disperse it evenly for 30-60 minutes;

[0049] S103: Add the obtained white solution into the PVDF transparent paste slurry, and continue stirring at 50-70°C for 1-3 hours to form a uniform white paste-like slurry, and then place the slurry in a vacuum drying oven for 30-60 minutes To extract air bubbles present in the slurry;

[0050] S104: Slowly pour the slurry into the prepared mold, use a scraper to disperse ...

Embodiment 1

[0079] 1. First, dissolve 5-7g NaOH in 20-40ml deionized water to prepare a strong alkaline solution environment, and stir at room temperature for 10-20min to completely dissolve NaOH in deionized water. Add 0.6~0.8g Ba(Ac) to NaOH solution 2 , 0.2~0.3gTiO 2 , Continue to stir at room temperature for 30-60 minutes to disperse the solution evenly.

[0080] 2. Transfer the mixed solution to an autoclave, and heat it in an oven at 200°C for 24 hours to generate the target product BaTiO 3 .

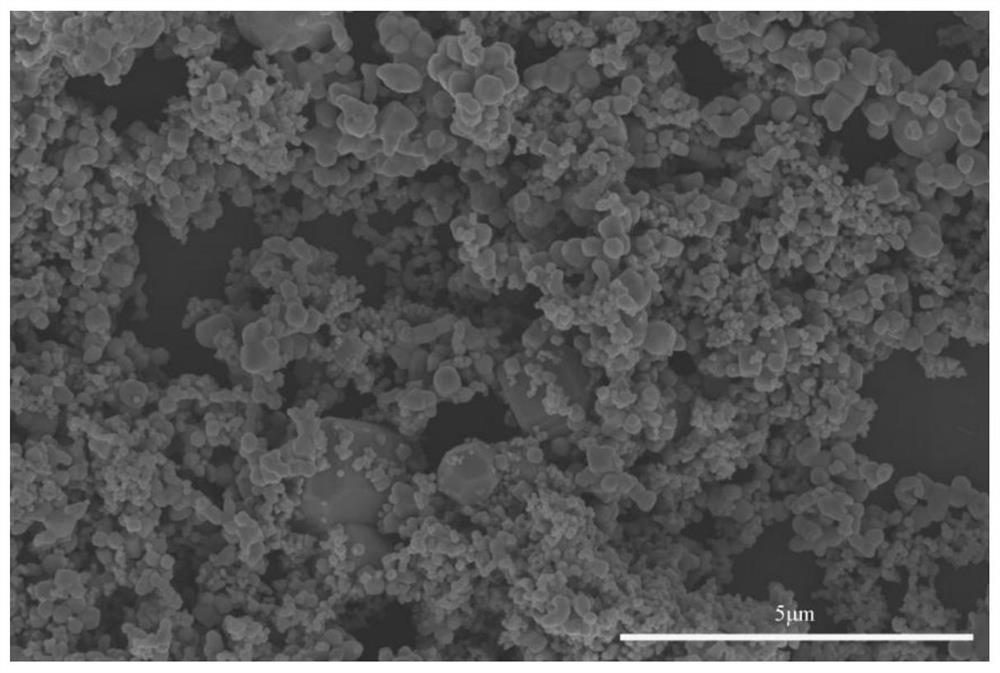

[0081] 3. Centrifuge the obtained precipitate, wash the obtained product with deionization and ethanol respectively, and centrifuge for 5 to 7 times; dry the product at 60-80°C, and roast the obtained powder at 900-1100°C for 1-2 3h. That is, get 150-200nm BaTiO 3 Material.

[0082] 4. Add 1-2g PEG, 0.382g (0.19g, 0.57g, 0.76g) Zn(Ac) 2 Dissolve in 30-40ml of deionized water, stir at room temperature for 10-30min to dissolve completely.

[0083] 5. Add the product obtained in step 3 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com