Catalyst for ammoxidation of propylene, method for preparing same, and method for ammoxidation of propylene by using same

A catalyst, ammonia oxidation technology, applied in catalyst activation/preparation, hydrocarbon ammoxidation preparation, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problems of insufficient research on structure and performance, limited conversion rate selectivity, etc. , to achieve the effect of high catalytic efficiency and reactivity, high selectivity and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0079] Preparation method of ammoxidation catalyst for propylene

[0080] According to another embodiment of the present invention, there is provided a method for preparing the catalyst of the above-mentioned one embodiment using an impregnation method.

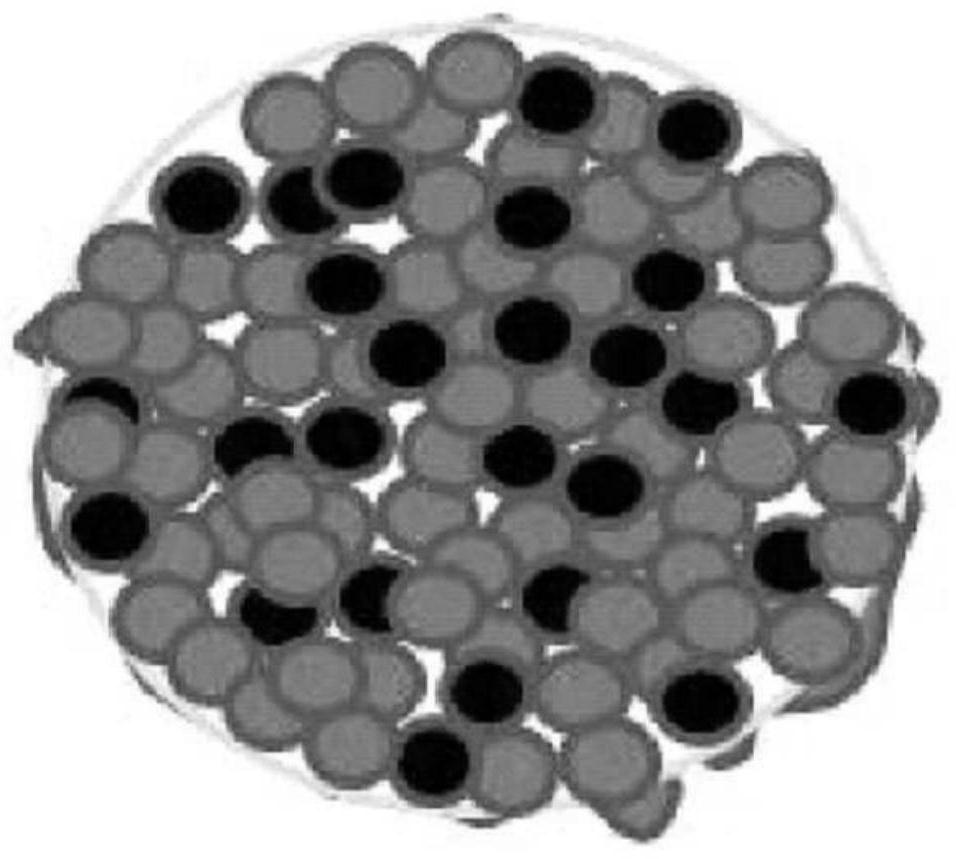

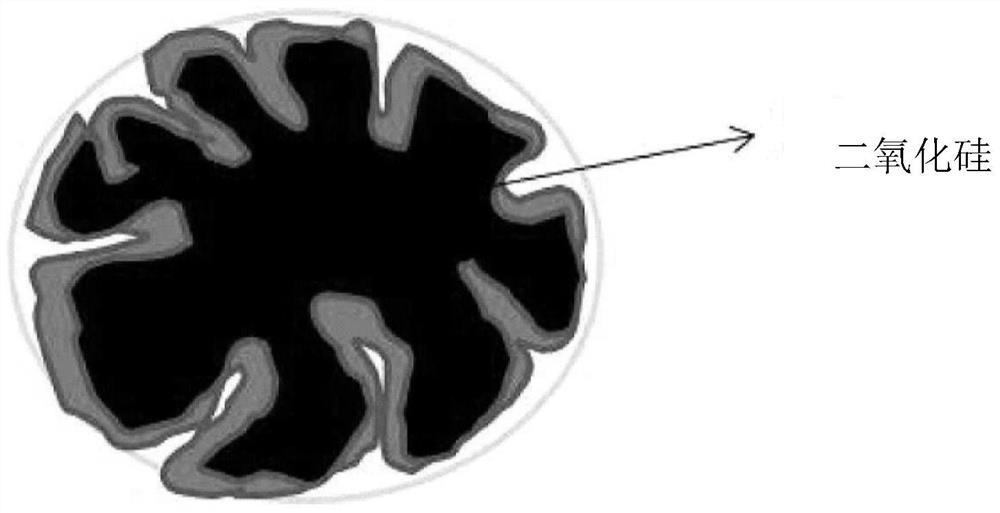

[0081] As briefly stated above, the catalyst of one embodiment can be prepared by loading a metal precursor solution on a silica support using a process of impregnation, drying, and then calcination.

[0082] More specifically, the preparation method of the catalyst of an embodiment comprises the following steps:

[0083] preparing a first precursor solution, the first precursor solution comprising a Mo precursor;

[0084] preparing a second precursor solution, the second precursor solution comprising Bi precursor, Fe precursor, A precursor (A = one or more elements in Ni, Mn, Co, Zn, Mg, Ca and Ba) and B precursors (B = one or more elements in Li, Na, K, Rb and Cs);

[0085] mixing the first precursor solution and the sec...

Embodiment 1

[0129] (1) Preparation process of precursor solution

[0130] In distilled water at 60 °C, 10.592 g of Mo precursor ((NH 4 ) 6 Mo 7 o 24 ) and 3.18 g of citric acid, and mixed to prepare a Mo precursor solution.

[0131] Separately, in distilled water at room temperature, 1.819 g of Bi precursor (Fe(NO 3 ) 3 ·5H 2 O), 9.488g Co precursor (Co(NO 3 ) 2 ·6H 2 O), 2.990g Fe precursor (Fe(NO 3 ) 2 9H 2 O) and 0.354g K precursor (KNO 3 ), and add 2.16g nitric acid (HNO 3 ), and then, they were mixed to prepare a mixed solution of Bi, Fe, Co and K precursors.

[0132] The Mo precursor solution; and the mixed solution of Bi, Fe, Co and K precursors are mixed to form a mixed solution of Mo, Bi, Fe, Co and K precursors.

[0133] In the mixed solution of the precursor, the total amount of distilled water was 54.07 g.

[0134] (2) Process of loading precursor solution in silica carrier (using impregnation method)

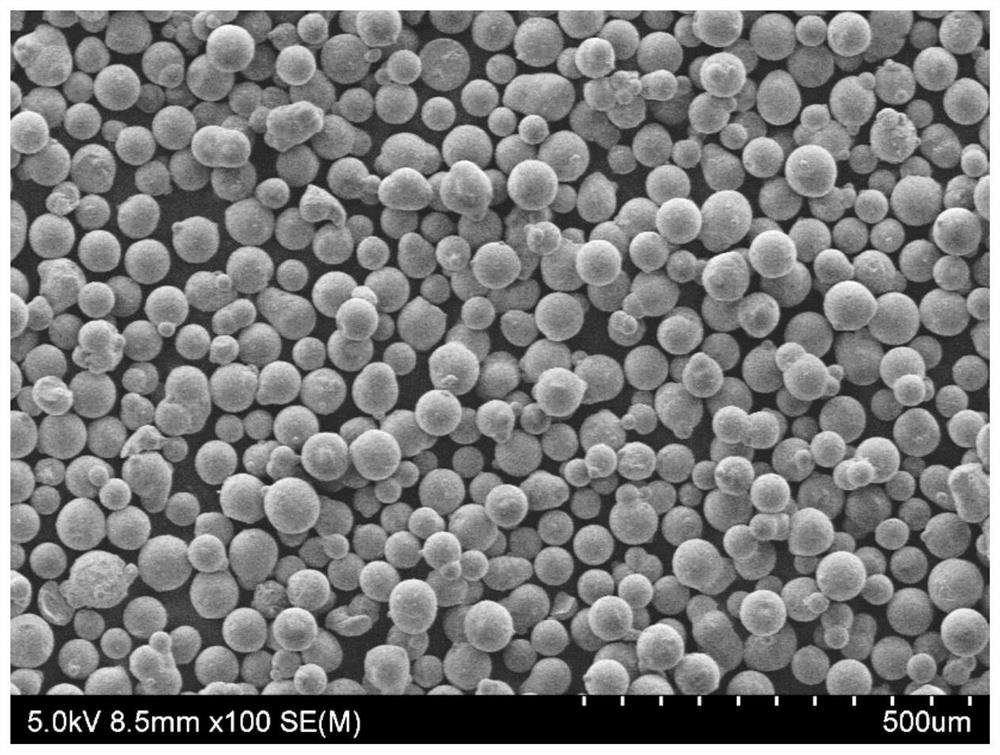

[0135] The D50 particle size is 55μm, the inner pore size...

Embodiment 2 to Embodiment 7

[0147] (1) Preparation process of catalyst (using impregnation method)

[0148] Each catalyst of Example 2 to Example 7 was prepared by the same method as Example 1, except that a precursor solution was prepared according to the composition described in Table 1 below, and a silica carrier described in Table 2 below was used.

[0149] (2) Ammoxidation process of propylene

[0150] The ammoxidation process of propylene was carried out using each catalyst of Examples 2 to 7 instead of Example 1, and then, the product was recovered and analyzed by the same method as Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| D50 | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com