Sealing agent for screw member and screw member obtained using same

A sealant and component technology, applied in the direction of connecting components, threaded fasteners, screws, etc., can solve problems such as poor operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

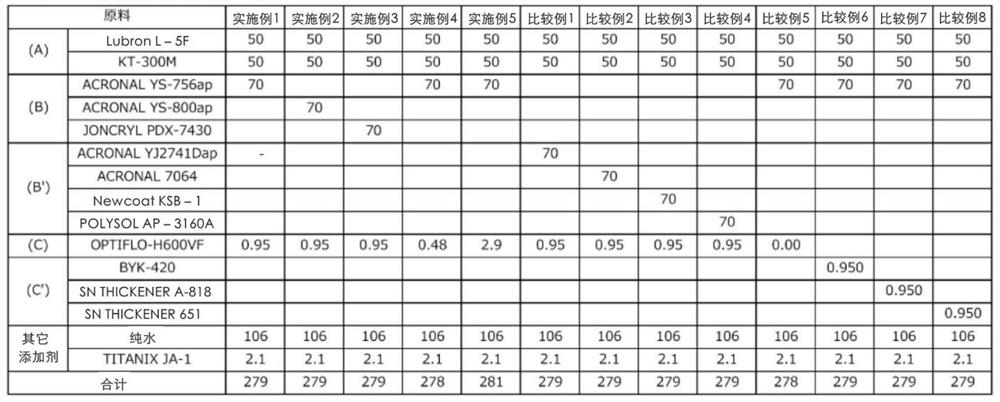

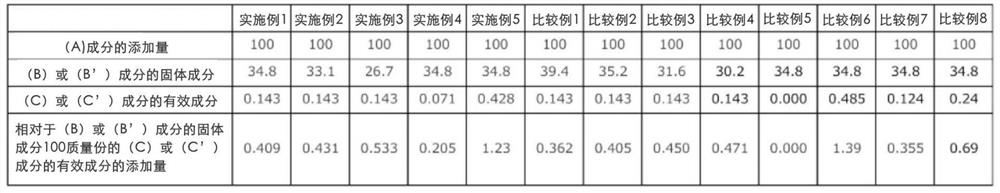

[0133] Examples 1-3 fixed various addition amounts, and changed the kind of (B) component. In Examples 4 and 5, the addition amount of (C) component was changed with respect to the compounding of Example 1. These were found to be excellent in the evaluation items of sagging, adhesiveness, and adhesiveness at the time of water adhesion. Among them, in Example 1 in which a material having a glass transition temperature Tg of 16°C was used, the maximum resistance moment when the nut was tightened was 3.0 N·m in both the adhesiveness and the adhesiveness evaluation at the time of water adhesion. The following and lower, become good results.

[0134] In addition, it can be seen from Example 4 that when the addition amount of the active ingredient of the component (C) is 0.205 parts by mass relative to 100 parts by mass of the solid content of the component (B), drooping does not occur, but the sealing agent flows from the screwed part to the The front end of the screw moves. Fro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com