Self-compacting concrete and preparation method thereof

A self-compacting concrete and concrete technology, applied in the field of concrete, can solve problems such as air bubbles, cavities, and poor vibration compaction effect, and achieve the effect of reducing bleeding phenomenon, increasing self-compacting effect, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

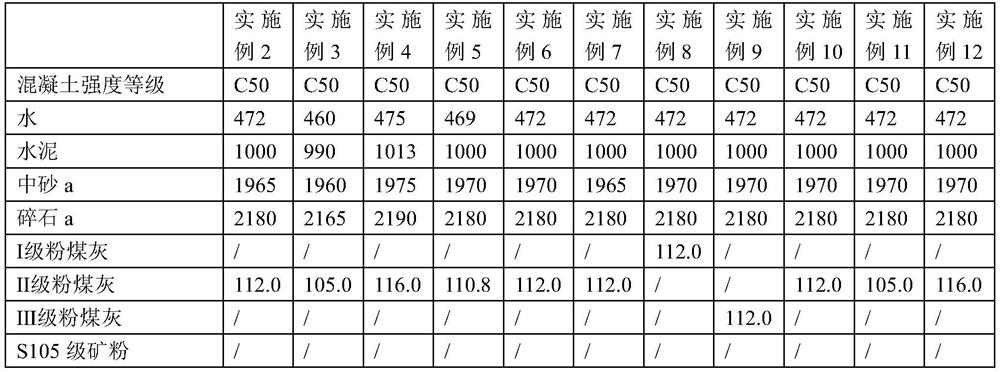

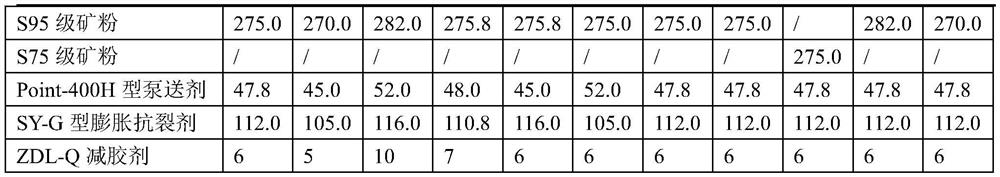

[0037] Examples of Preparation of Raw Materials and / or Intermediates

[0038] Water: Use tap water.

[0039] Cement: purchased from Guangxi China Resources Hongshuihe Cement Co., Ltd. This application specifically takes P.O42.5 cement (ordinary Portland cement with a strength of 42.5) as an example for illustration.

[0040] Medium sand: purchased from Shanghai Jiyun Building Materials Co., Ltd., mud content ≤ 0.01%, moisture content ≤ 0.01%, model is yellow sand; this application uses medium sand a (fineness modulus 2.4-2.8), medium sand b ( The fineness modulus is 2.9-3.4), medium sand c (fineness modulus is 1.8-2.2) as examples to illustrate.

[0041] Crushed stone: purchased from Chengdu Anxinda Sand and Stone Sales Co., Ltd., with a mud content of ≤1.5% and a moisture content of ≤2%. 20-40mm) as an example to illustrate.

[0042]Fly ash: Class F fly ash purchased from Shanghai Shifa Electric Power Fly Ash Co., Ltd. Class I fly ash has a sieve residue of 10.5% (0.045mm ...

Embodiment 1

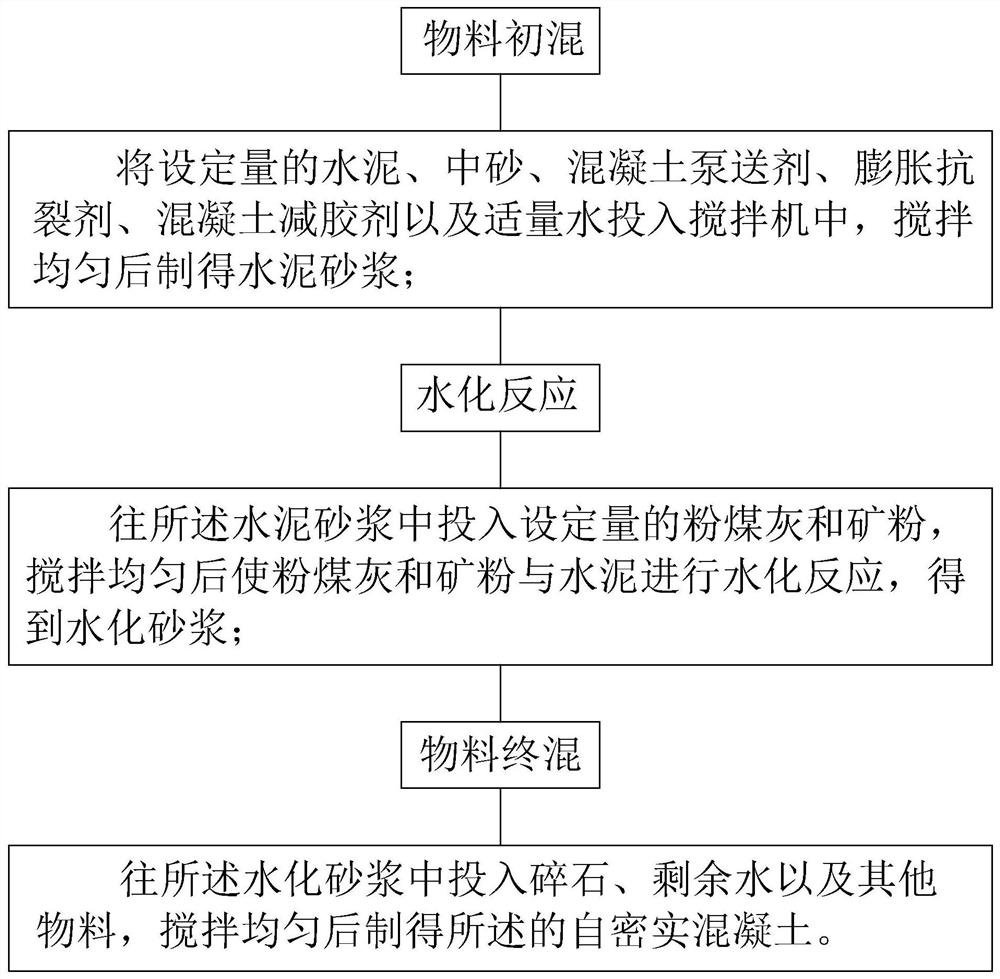

[0052] A method for preparing self-compacting concrete, comprising the steps of:

[0053] 1000g cement, 1970g medium sand a, 47.8g Point-400H pumping agent, 110.8g SY-G expansion anti-cracking agent, 6g concrete glue reducer, 110.8g Ⅱ grade fly ash, 375.8g S95 grade mineral powder, Put 2180g of crushed stone and 472g of water into the mixer, and stir for 35 minutes until the materials are evenly mixed to obtain self-compacting concrete.

Embodiment 2

[0055] A method for preparing self-compacting concrete, combining figure 1 , including the following steps:

[0056] ①. Initial mixing of materials: 1000g cement, 1970g medium sand a, 47.8g Point-400H pumping agent, 110.8gSY-G expansion anti-cracking agent, 6g concrete glue reducer and 354g water (usually the total water consumption first 3 / 4) into the mixer, and stir for 10 minutes until the materials are evenly mixed to obtain cement mortar;

[0057] ②. Hydration reaction: Put 110.8g of grade II fly ash and 375.8g of S95 grade mineral powder into the cement mortar in step ①, stir for 15 minutes until the materials are evenly mixed, and then make the grade II fly ash and S95 grade mineral powder and cement Hydration reaction to obtain hydration mortar; ③, final mixing of materials: put 2180g of gravel and remaining 118g of water into the hydration mortar in step ②, stir for 10min until the materials are evenly mixed to obtain self-compacting concrete.

[0058] Among them, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com