A kind of preparation method of environment-friendly phosphate ester fire-resistant hydraulic oil

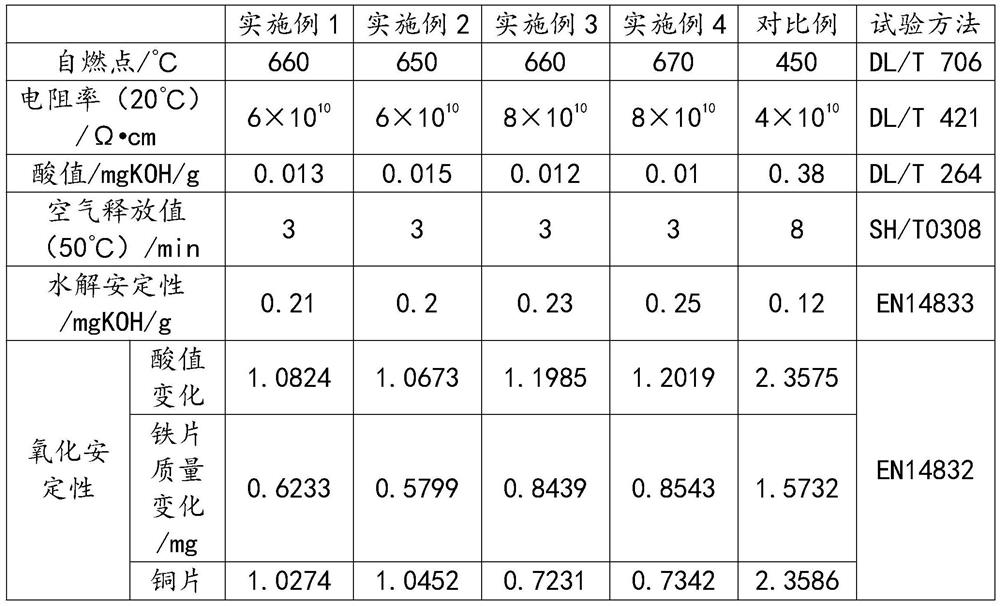

A phosphate ester and hydraulic oil technology, applied in the direction of lubricating compositions, etc., can solve the problems that TXP cannot meet the equipment requirements, high toxicity, poor hydrolytic stability and oxidation stability, etc., and achieve excellent oxidation stability and hydrolytic stability, spontaneous combustion The effect of high dot height and high volume resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A preparation method of an environment-friendly phosphate ester fire-resistant hydraulic oil, comprising the steps of:

[0031] Step S1: Add phenol, 1-phenoxy 2-propanol, and triethylamine into a 1000mL four-neck flask with a condenser tube and a thermometer, heat the system to 30°C under nitrogen protection, and drop liquid with 500mL constant pressure Add phosphorus oxychloride dropwise to the system through the funnel, and the dropping time is 0.5h. After the dropping is completed, the temperature of the system is raised to 60°C. The absorption of sodium solution produces hydrogen chloride gas;

[0032] Step S2: After no hydrogen chloride gas is produced, stop the reaction and carry out vacuum distillation to remove phenol and phosphorus oxychloride, and carry out distillation at a temperature of 150° C. and a pressure of 100 Pa to obtain phosphoric acid ester A1.

[0033] The formulation of the high-temperature flame-resistant phosphate ester hydraulic oil prepared...

Embodiment 2

[0037] A preparation method of an environment-friendly phosphate ester fire-resistant hydraulic oil, comprising the steps of:

[0038] Step S1: Add phenol, 1-phenoxy 2-propanol, and triethylamine into a 1000mL four-neck flask with a condenser tube and a thermometer, heat the system to 80°C under nitrogen protection, and drop liquid with 500mL constant pressure Add phosphorus oxychloride dropwise to the system through the funnel, and the dropping time is 3 hours. After the dropping is completed, the temperature of the system is raised to 110°C. The solution absorbs and produces hydrogen chloride gas;

[0039] Step S2: After no hydrogen chloride gas is produced, stop the reaction and carry out vacuum distillation to remove phenol and phosphorus oxychloride, and carry out distillation at a temperature of 200° C. and a pressure of 100 Pa to obtain phosphoric acid ester A2.

[0040] The formula for preparing high-temperature flame-resistant phosphate ester hydraulic oil with phosp...

Embodiment 3

[0044] A preparation method of an environment-friendly phosphate ester fire-resistant hydraulic oil, comprising the steps of:

[0045] Step S1: Add isooctyl alcohol, phenoxyethanol, and anhydrous magnesium chloride into a 1000mL four-neck flask with a condenser and a thermometer, heat the system to 80°C under nitrogen protection, and inject Phosphorus oxychloride was added dropwise for 5 hours. After the dropwise addition, the temperature was raised to 120°C. After holding for 2 hours, the temperature was raised to 250°C for 3 hours, and absorbed by sodium hydroxide solution to generate hydrogen chloride gas;

[0046] Step S2: After no hydrogen chloride gas is produced, stop the reaction and carry out vacuum distillation to remove phenol and phosphorus oxychloride, and carry out distillation at a temperature of 250° C. and a pressure of 10 Pa to obtain phosphoric acid ester B1.

[0047] The formulation of high temperature flame-resistant phosphate ester hydraulic oil prepared ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| autoignition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com