Anti-antipolar PtIr/CNT catalyst for proton exchange membrane fuel cell and preparation method of anti-antipolar PtIr/CNT catalyst

A proton exchange membrane and fuel cell technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of battery initial performance decline, poor conductivity of oxides, additional preparation, etc., to improve reverse electrode tolerance, good The effect of simple performance and preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

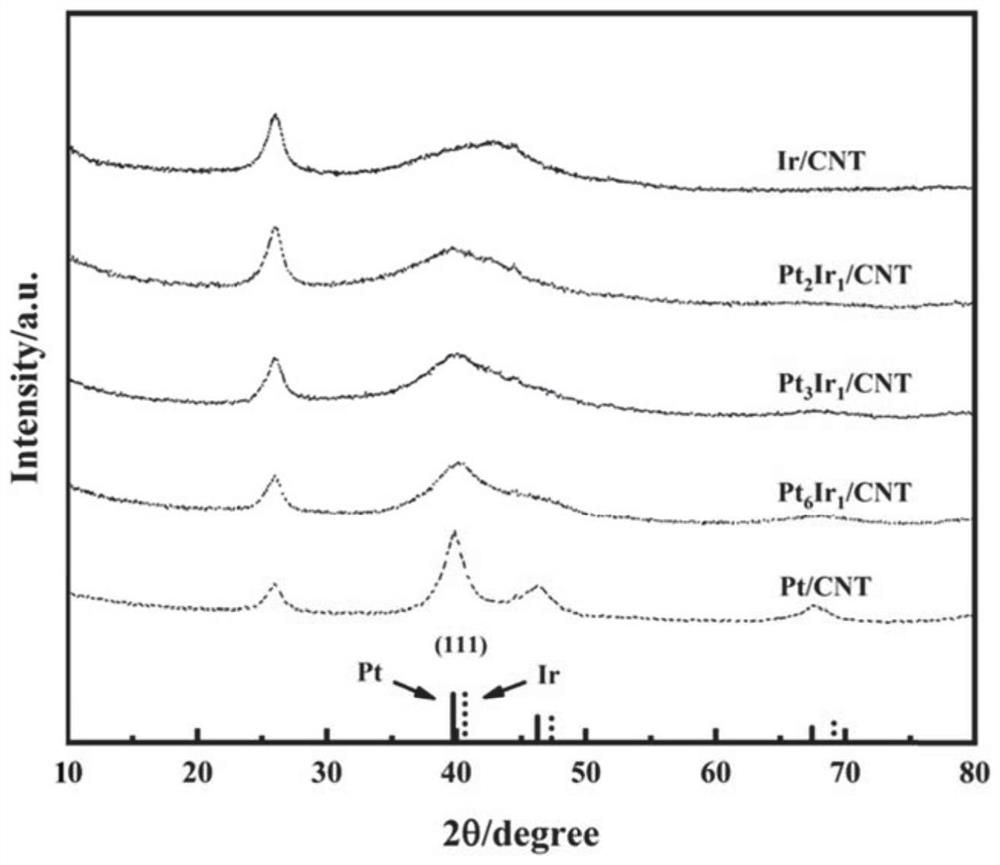

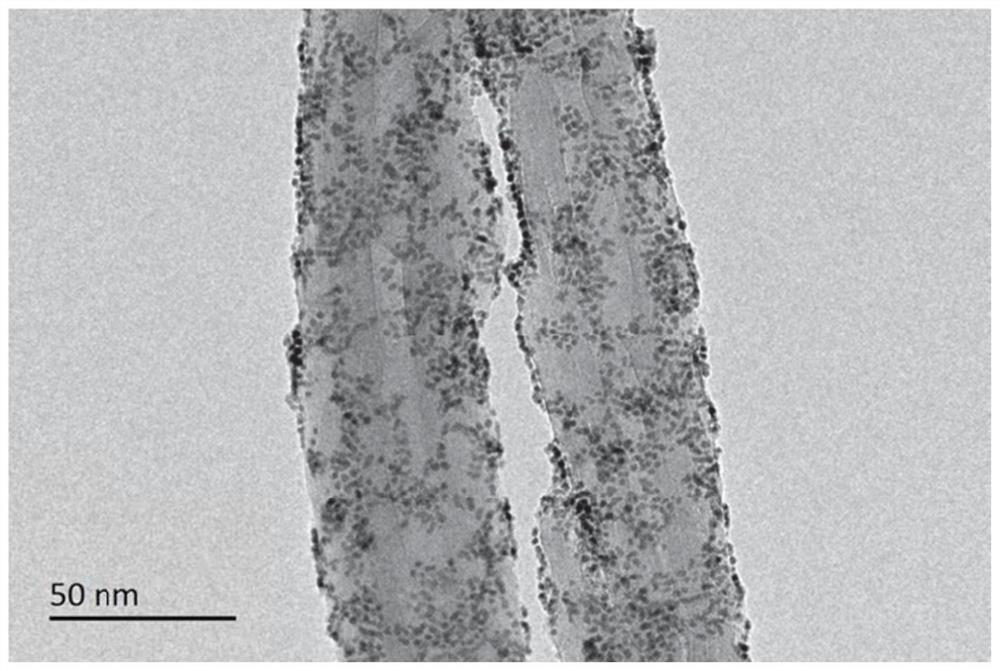

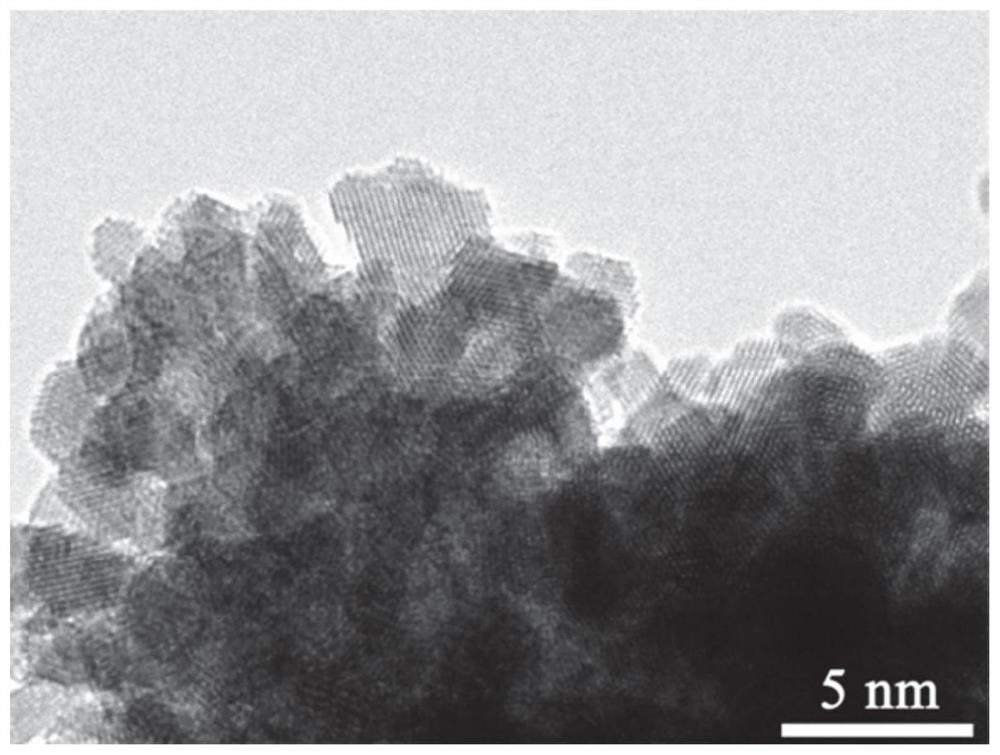

Embodiment 1

[0042] Take 1 g of carbon nanotubes and disperse them in a mixed acid solution with a volume ratio of concentrated sulfuric acid and concentrated nitric acid of 3:1 (the total volume is 200 mL). The concentrated sulfuric acid and concentrated nitric acid used are both commercially available concentrated sulfuric acid and concentrated nitric acid. Heat for 3 hours, add a large amount of deionized water to filter and wash until the pH is 7.0, and dry in an oven.

[0043]Take 155 mg of acid-treated carbon nanotubes and add them to a three-necked flask, add 20 mL of deionized water and 20 mL of ethylene glycol, ultrasonically disperse for 30 min, then add 3.7 mg / mL of chloroplatinic acid and 2.7 mg / mL of iridium trichloride, so that The molar ratio of Pt and Ir is 3:1, and the total metal molarity is 0.2mM. Then nitrogen is passed through to remove oxygen for 30min, and then the pH is adjusted to above 10 with 2mol / L NaOH solution. Move the three-necked flask to an oil bath at 140...

Embodiment 2

[0056] Take 1 g of carbon nanotubes and disperse them in a mixed acid solution with a volume ratio of concentrated sulfuric acid and concentrated nitric acid of 3:1. The deionized water was filtered and washed until the pH was 7.0, and dried in an oven.

[0057] Take 155 mg of acid-treated carbon nanotubes and put them into a three-necked flask, add 20 mL of deionized water and 20 mL of ethylene glycol with a volume ratio of 1:1 (40 mL in total), ultrasonically disperse for 30 min, and then add 3.7 mg / mL of chlorine Platinic acid and 2.7mg / mL iridium trichloride, so that the molar ratio of Pt and Ir is 2:1, and the total metal molar weight is 0.2mM chloroplatinic acid and iridium trichloride, followed by nitrogen deoxygenation for 30min, Then adjust the pH to above 10 with 2mol / L NaOH solution. Move the three-necked flask to an oil bath at 140°C and heat it for 10 hours. During this period, nitrogen gas is kept flowing. After the reaction is completed, it is naturally cooled ...

Embodiment 3

[0061] Take 1 g of carbon nanotubes and disperse them in a mixed acid solution with a volume ratio of concentrated sulfuric acid and concentrated nitric acid of 3:1. The deionized water was filtered and washed until the pH was 7.0, and dried in an oven.

[0062] Take 155 mg of acid-treated carbon nanotubes and put them into a three-necked flask, add 20 mL of deionized water and 20 mL of ethylene glycol with a volume ratio of 1:1 (40 mL in total), ultrasonically disperse for 30 min, and then add 3.7 mg / mL of chlorine Platinic acid and 2.7mg / mL iridium trichloride, so that the molar ratio of Pt and Ir is 6:1, the total metal molar weight is 0.2mM chloroplatinic acid and iridium trichloride, followed by nitrogen deoxygenation for 30min, Then adjust the pH to above 10 with 2mol / L NaOH solution. Move the three-necked flask to an oil bath at 140°C and heat it for 10 hours. During this period, nitrogen gas is kept flowing. After the reaction is completed, it is naturally cooled to r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com