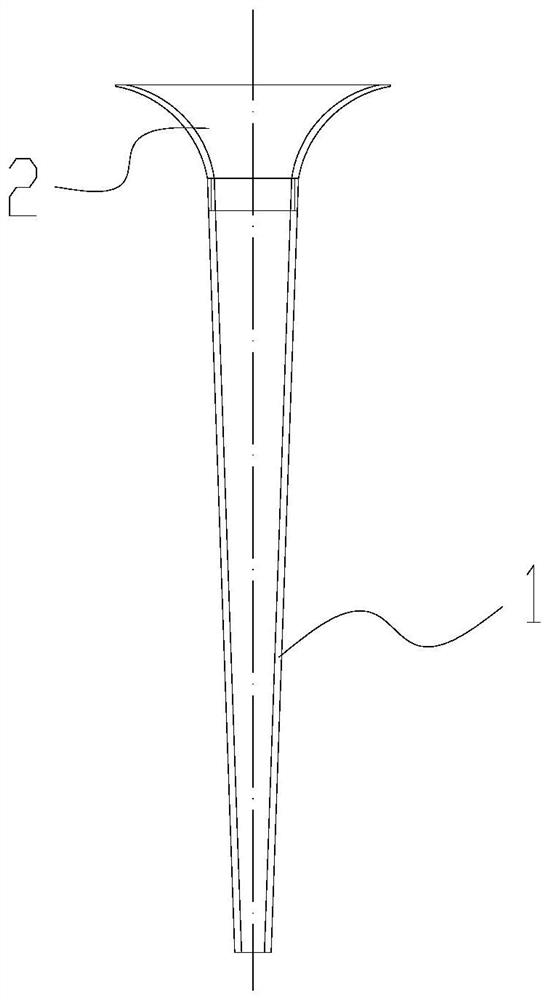

TC4 ultrasonic scalpel and manufacturing method thereof

A manufacturing method and scalpel technology, applied in the field of medical equipment, can solve problems such as blocked reflection of ultrasonic frequency electrical signals, high energy consumption of sound wave transmission, and slowed guided wave speed, so as to avoid guided wave reflection, reduce energy loss, and reduce wave band more concentrated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Method Example 1: Summer or my country Working Time, use TC4 titanium alloy steel pipe, outer diameter 3.2mm, wall thickness 1.0mm, length due to multi-segment continuous processing, according to the equipment. When the tapered tube of the tungsten steel three-roll concentric mold, the coreless roll-back molding is performed, and when the tapered section itself rotates, the tungsten steel three-roll concentric mold combination is round-trip movement along the length of the tube section; keep it The steel pipe is formed under the rolling oil lubrication conditions of 45 ° C; each time-shaped variable is controlled within the length of each 1 mm, and the radial variation is 0.025 mm. Rolling oil is prepared according to quality: 50% of chlorinated wax wax, 32 # machinery oil 25%, saponified oil 10%, and the remaining 15% is a yellow wine with 12 degrees of alcohol.

Embodiment 2

[0029] Method Example 2 2: Use TC4 titanium alloy steel pipe, 3.2 mm outer diameter, 1.0 mm wall thickness, and length. When the tapered tube of the tungsten steel three-roll concentric mold, the coreless roll-back molding is performed, and when the tapered section itself rotates, the tungsten steel three-roll concentric mold combination is round-trip movement along the length of the tube section; keep it The steel pipe is formed in the rolling oil lubrication conditions of 48 ° C; each of the variables is controlled over the range per 1 mm length, and the radial variation is 0.025 mm. Rolling oil is prepared according to quality: chlorinated wax 46%, 32 # machinery oil 30%, saponified oil 8%, and 16% is a yellow wine for 13 degrees of wine.

Embodiment 3

[0030]Method Example 3: Winter or cold area working hours, use TC4 titanium alloy steel pipe, outer diameter of 3.2 mm, wall thickness 1.0 mm, length. When the tapered tube of the tungsten steel three-roll concentric mold, the coreless roll-back molding is performed, and when the tapered section itself rotates, the tungsten steel three-roll concentric mold combination is round-trip movement along the length of the tube section; keep it The steel pipe is formed in the rolling oil lubrication conditions of 50 ° C; each of the variables is controlled within the length of each 1 mm, and the radial variation is 0.025 mm. Rolling oil is prepared according to quality percentage: 45% of chlorinated wax wax, 35% of 32 # machinery oil, 5% saponified oil, and the remaining 15% is a yellow wine having a 50 degree of wine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific heat capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com