Implantable catheter, use method and preparation method thereof

An implantable catheter technology, which is applied in the direction of catheters, cardiac catheters, balloon catheters, etc., can solve the problems of patient infection, poor pressure measurement accuracy, easy to fall off heparin coating, etc., and achieve the effect of reducing the diameter and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

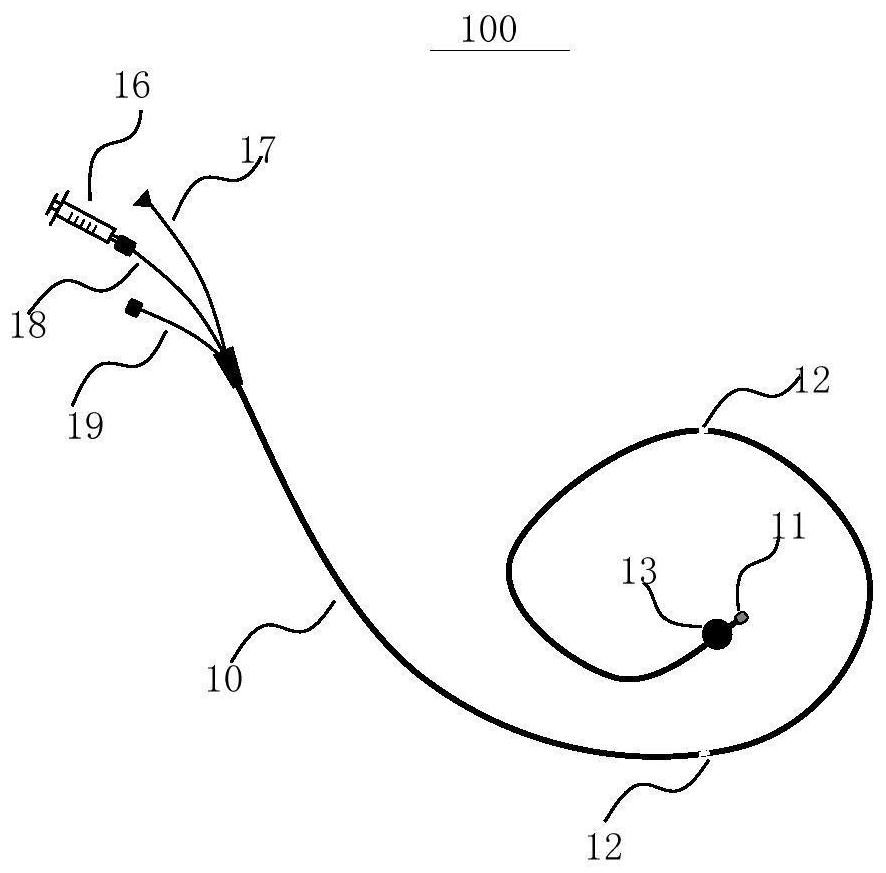

[0080] This example involves a method for installing a single first pressure sensor with a size not exceeding 1mm×1mm×0.5mm on the pipe body, which specifically includes the following steps:

[0081] In the first step, the inflatable cavity at the distal end of the tube is sealed, and the sealing distance does not exceed 3cm;

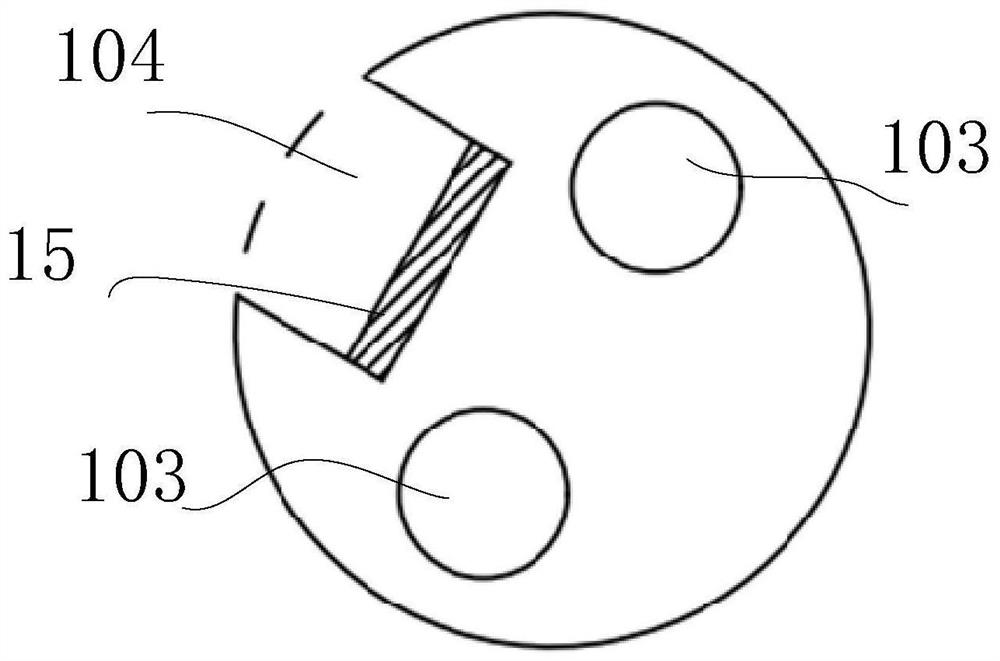

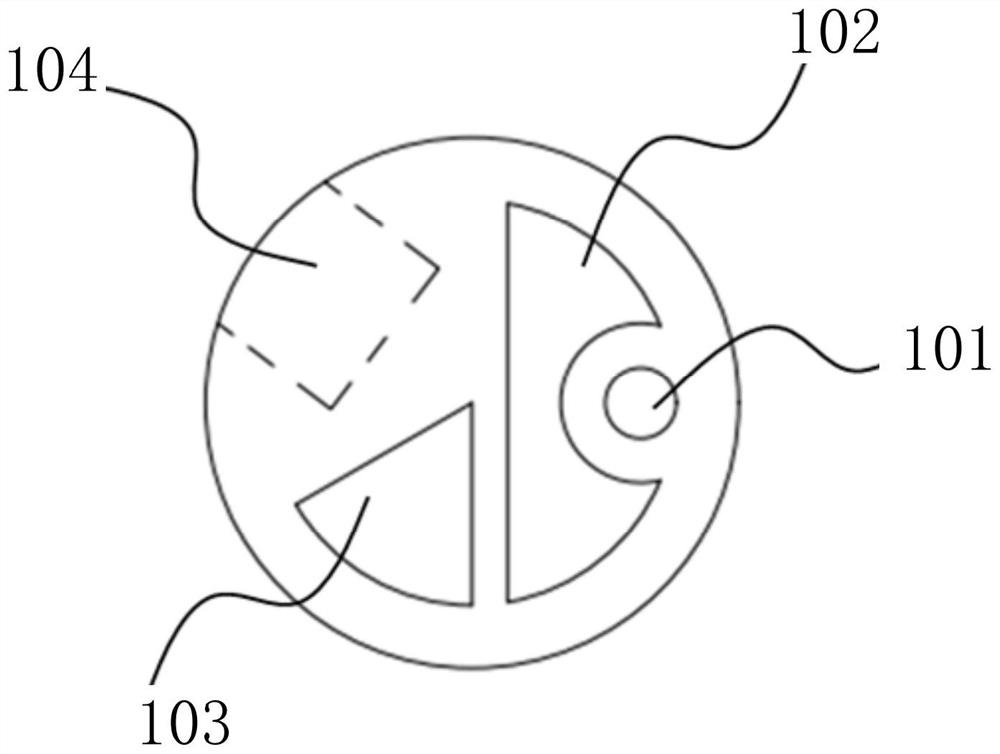

[0082] In the second step, the Figures 8a-9d The first base shown in is connected to the far end of the tube body by means of AB glue bonding, and a hole is opened on the side wall of the tube body to reserve a through channel with the guide wire lumen;

[0083] The third step is to operate under a microscope, and use photosensitive UV glue to glue the first pressure sensor on the first base at the far end, and guide the lead wires into the wire lumen through the holes on the side wall;

[0084] The fourth step is to use a silicone sleeve to protect the position where the sensor is installed on the tube body with protective adhesive to ensure airtight...

Embodiment 2

[0090]This embodiment relates to a method for installing the first pressure sensor and the second pressure sensor with a size not exceeding 1mm×1mm×0.5mm on the pipe body, that is, installing the first pressure sensor at the far end of the pipe body, and installing the second pressure sensor on the side wall of the pipe body. Two second pressure sensors, for a total of three sensors. Specifically include the following steps:

[0091] In the first step, the inflatable cavity at the distal end of the tube is sealed, and the sealing distance does not exceed 3 cm;

[0092] In the second step, the Figures 8a-9d The first base described in is connected to the far end of the tube body by AB glue bonding; and a hole is opened on the side wall of the tube body to reserve a through channel with the guide wire lumen;

[0093] The third step is to operate under a microscope, use photosensitive UV glue to glue the first pressure sensor on the first base, and guide the lead wires into th...

Embodiment 3

[0101] This embodiment relates to a method for installing a first pressure sensor with a size not exceeding 2mm×2mm×1mm on a pipe body, which specifically includes the following steps:

[0102] In the first step, the inflatable cavity at the distal end of the tube is sealed, and the sealing distance does not exceed 3cm;

[0103] In the second step, the Figures 8a-9d The first base described in is connected to the far end of the tube body by AB glue bonding; and a hole is opened on the side wall of the tube body to reserve a through channel with the guide wire lumen;

[0104] The third step is to operate under a microscope, use photosensitive UV glue to glue the first pressure sensor on the first base, and use the same method to glue an adapter board behind the first pressure sensor;

[0105] The fourth step is to use a gold wire ball welding machine to connect one end of the adapter plate to the interface end of the first pressure sensor through a gold wire, then weld the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com