Method for intelligent trial preparation of 3D printing hybrid fiber concrete and control system

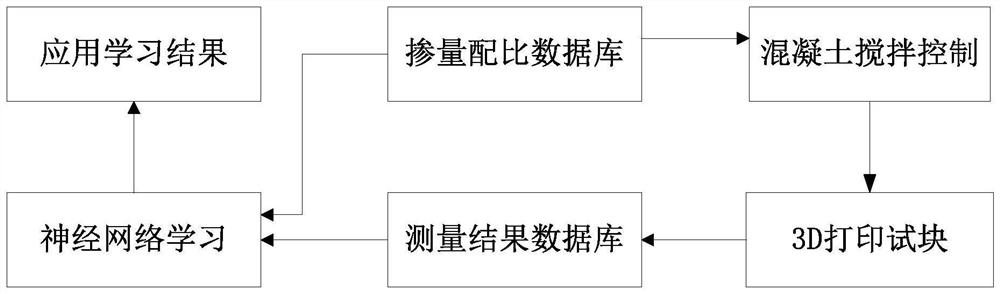

A 3D printing and hybrid fiber technology, which is applied in the direction of mixing operation control, mixing operation control device, clay preparation device, etc., can solve the inability to realize 3D printing concrete intelligent trial mix, 3D printing concrete input parameters and output parameters and the relationship between them beyond

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

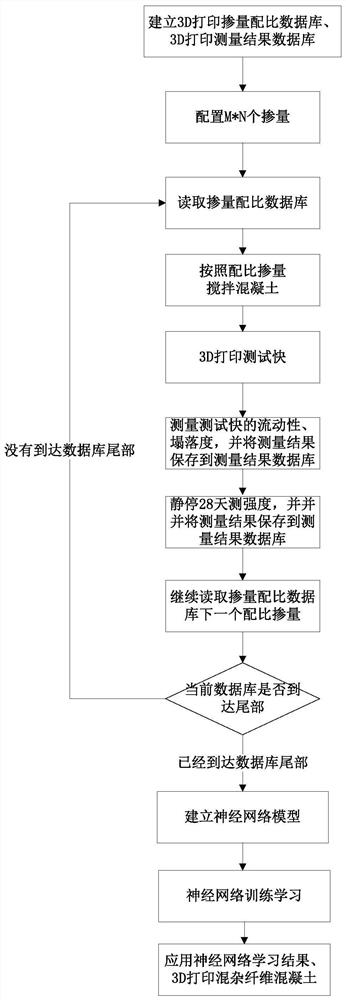

[0082] Next, a detailed description of a 3D printing high-performance hybrid fiber concrete technology of the present invention will be described below.

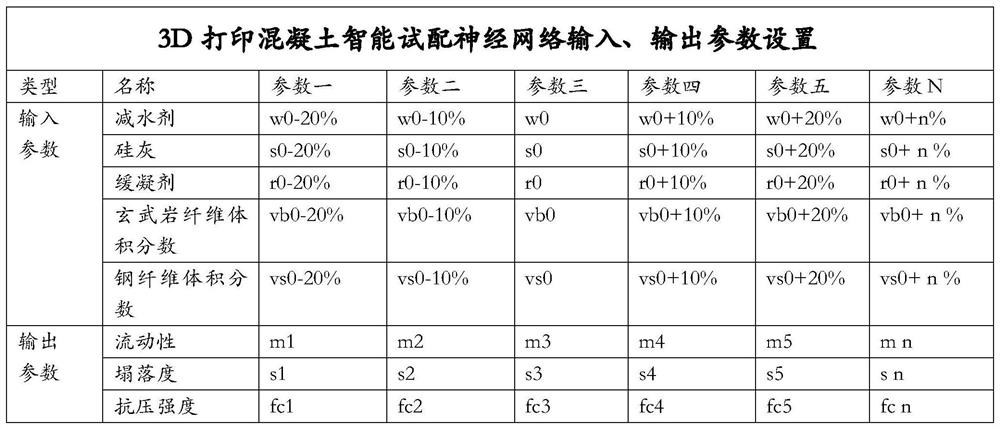

[0083] 1. Referring to the research results, the matching ratio of the printing concrete is preset, and the better concrete mix ratio is found. Based on the above-mentioned coordination ratio, the amount of water reduction agent, silicon ash, or soula, each duct is based on the reference ratio, and the ratio of 10%, 20%, reducing 10%, 20%, The components are printed with the composition of the components of the components, the fluid fluid performance of the test slurry.

[0084] 2, based on the above-mentioned optimal concrete ratio, the length of the short-cut fiber is determined on the basis of existing short-cut fiber concrete technology, and the incorporation of the incorporation in the concrete is 0.5%, 1.0%, 1.5% and 2.0. % Is basalt fiber, formulated basalt fiber concrete slurry, measuring fluidity and printability.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com