Spraying device and method for improving surface strength of PC bricks

A technology of surface strength and spray device, applied in ceramic molding machines, manufacturing tools, etc., can solve the problem of relying on manual operation for PC brick maintenance, and achieve better maintenance effect, intelligent production operation, and labor cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

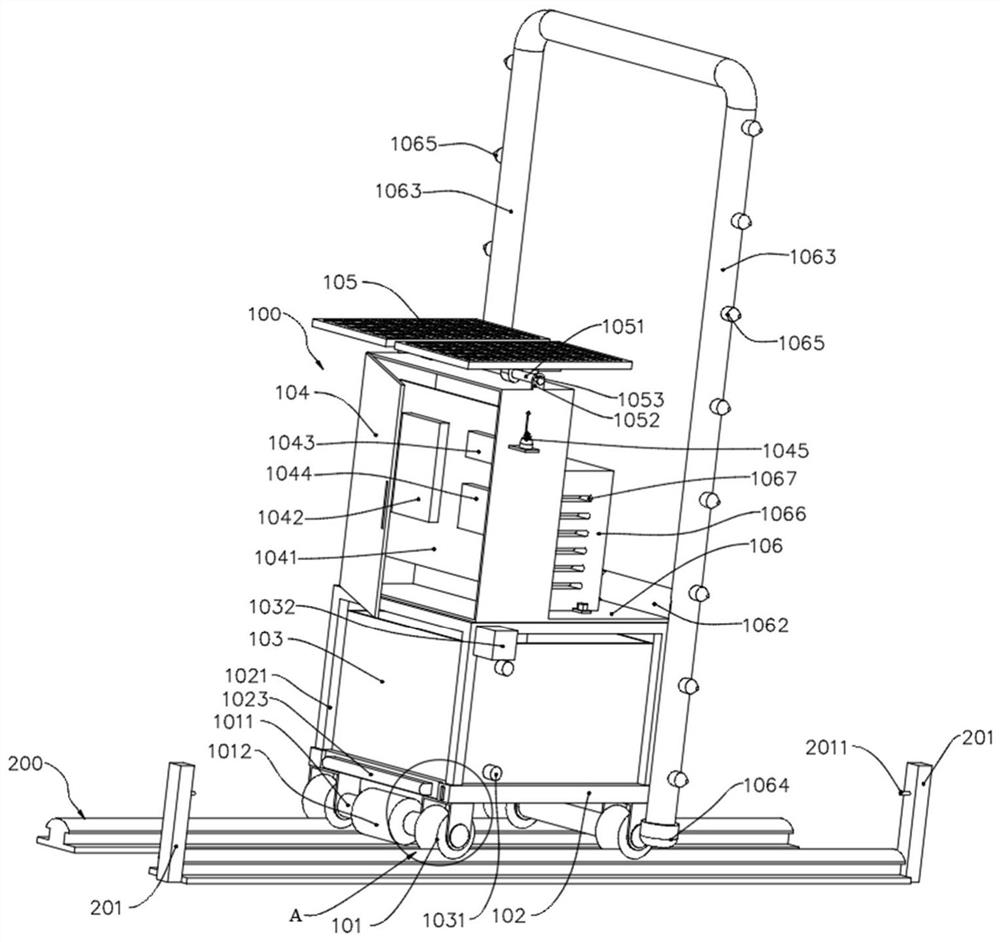

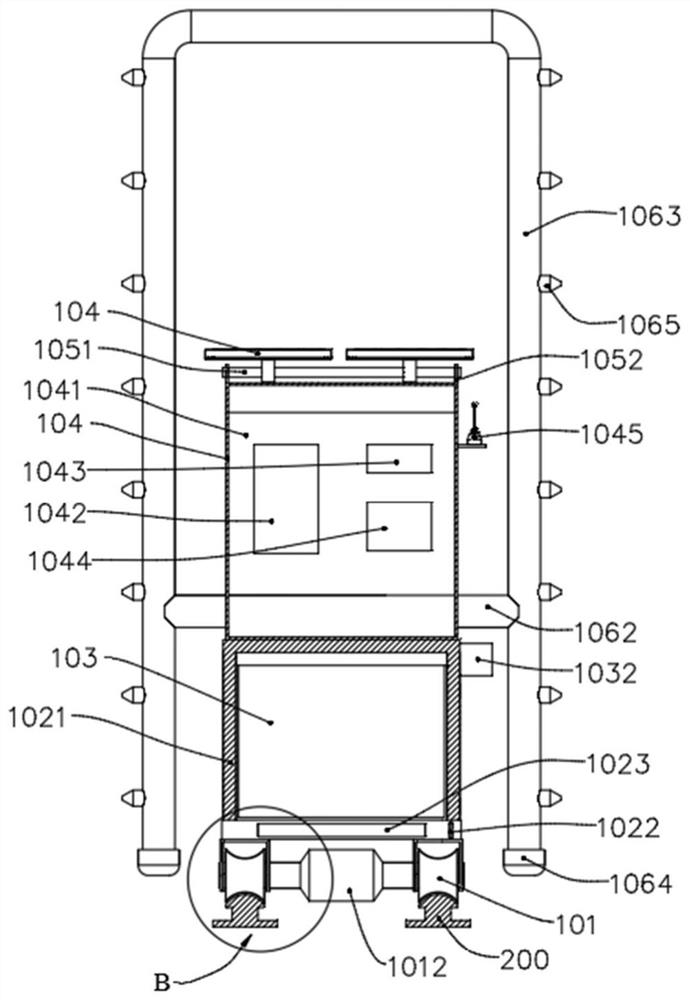

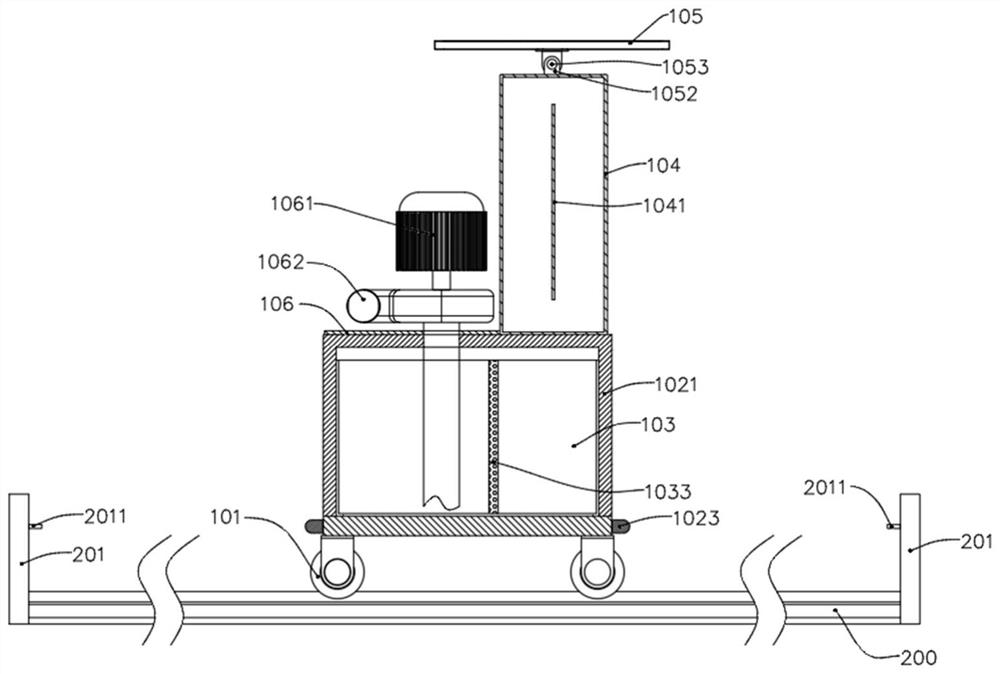

[0038] Refer to attached Figure 1-6 As shown, the present invention provides a technical solution: a spray device for improving the surface strength of PC bricks, comprising:

[0039] Spray trolley 100, spray trolley 100 comprises roller 101 and base 102, and roller 101 is arranged on the four corners of base 102 respectively, and the center of front and rear two groups of rollers 101 is respectively provided with connecting shaft 1011, wherein the middle part of a group of connecting shaft 1011 is provided with The drive motor 1012, the top of the base 102 is connected with a support 1021, the inside of the support 1021 is provided with a water storage tank 103, one side of the water storage tank 103 is provided with a liquid level probe 1031, and the liquid level probe 1031 is provided with two groups, which are respectively used to detect storage High water level and low water level in the water tank 103, the inside of the water storage tank 103 is provided with a filter p...

Embodiment 2

[0053] Refer to attached Figure 7 As shown, a kind of spraying method that the embodiment of the present invention provides to improve PC brick surface strength additionally, comprises the following steps:

[0054] S1, receiving the working signal, the operator uses a mobile phone or other terminal to connect to the wireless signal, and sets the working parameters of the sprinkler device;

[0055] S2, working environment detection, the liquid level sensor 1032 detects the water level in the water storage tank 103, the infrared sensor 1022 detects the position of the spray trolley 100 on the track 200, and transmits the signal to the controller 1044;

[0056] S3, spraying operation, the solar panel 105 absorbs sunlight, converts it into electrical energy and stores it in the power supply 1042, and provides power for the operation of the spraying trolley 100. According to the set parameters, the spraying trolley 100 starts the spraying operation, and the controller 1044 control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com