Gas isolation waterproof coiled material and processing technology thereof

A waterproof membrane and gas technology, applied in the direction of dust prevention, fire prevention, synthetic resin layered products, etc., can solve safety accidents, safety hazards, voids and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following is further described in detail through specific implementation methods:

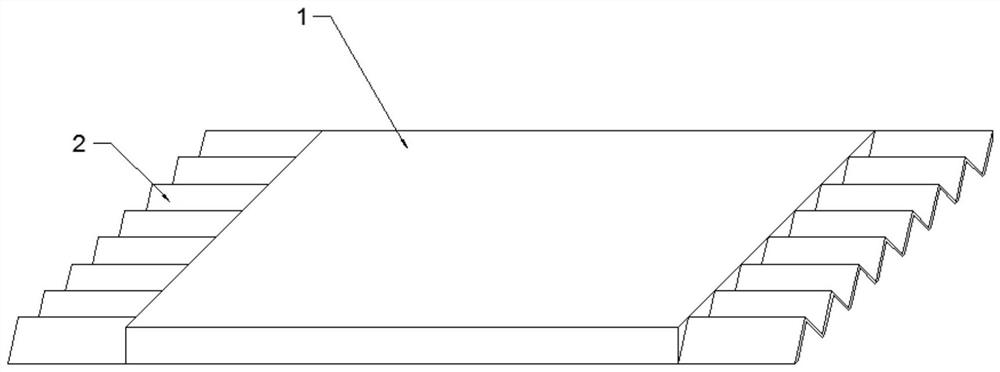

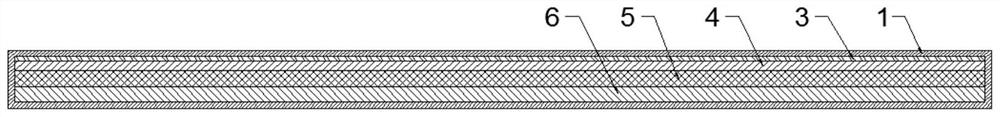

[0019] The reference signs in the accompanying drawings of the description include: the coiled material body 1 , the sawtooth end 2 , the plastic film layer 3 , the waterproof coating 4 , the grid layer 5 , and the fireproof layer 6 .

[0020] The embodiment is basically as attached figure 1 And attached figure 2 Shown:

[0021] A gas isolation and waterproof coiled material, comprising a coiled material body 1, the coiled material body 1 comprises a fireproof layer 6 made of ceramic fiber cotton, on which a grid layer 5 made of iron wire is pasted, and the diameter of the iron wire is 0.2- 0.5mm (preferably 0.3mm), the mesh layer 5 is coated with a waterproof coating 4 made of non-tar polyurethane, and the waterproof coating 4 is pasted with a plastic film layer 3, and some bumps are evenly distributed on the plastic film. The lower surface of the 6 and the upper surface of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com