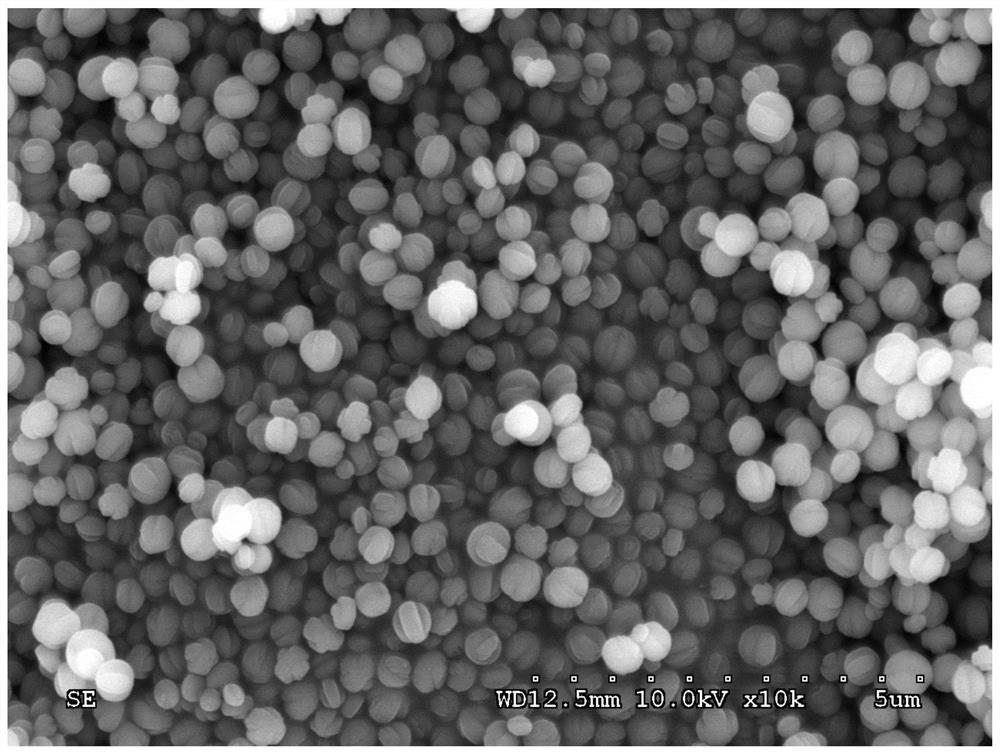

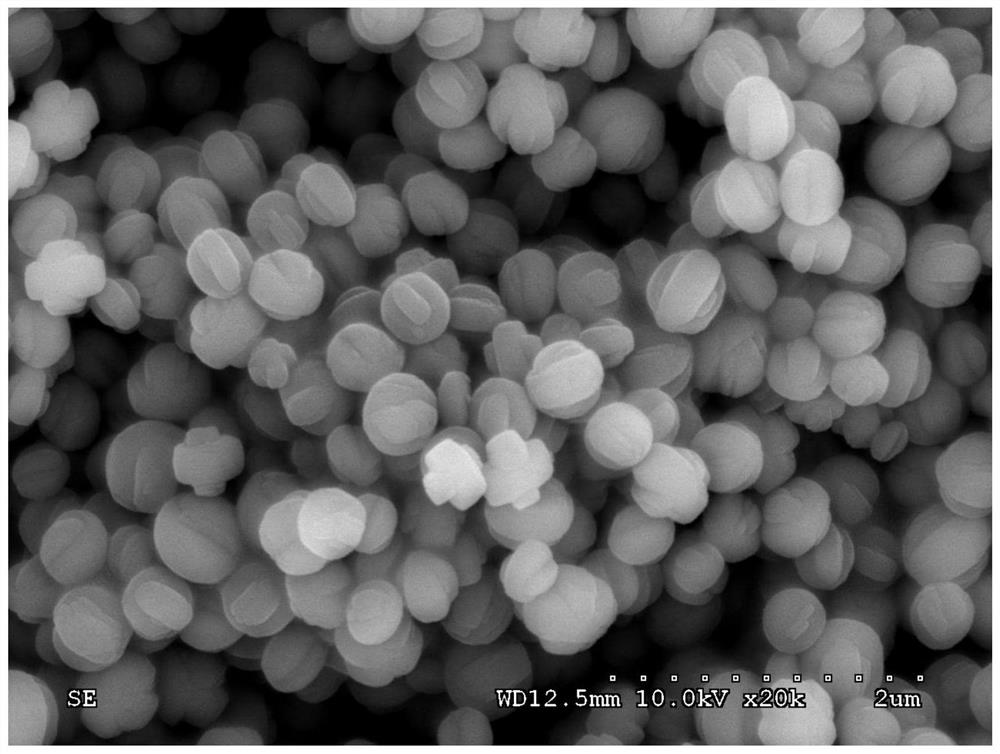

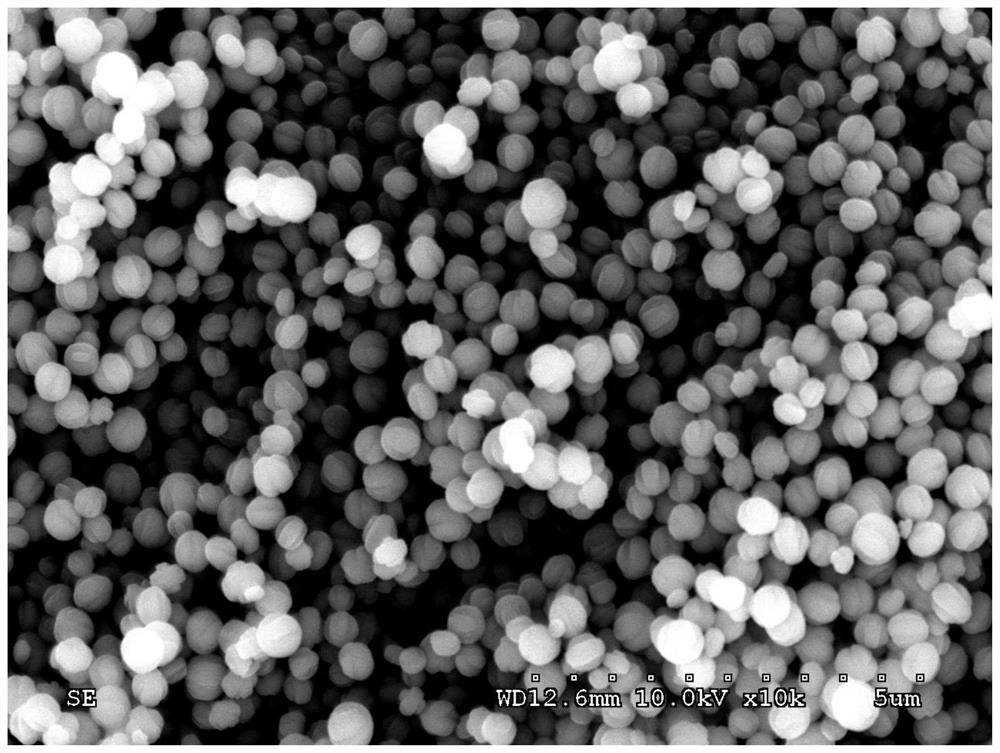

Preparation method of sphere-like porous silicon dioxide powder

A technology of porous silica and spherical shape, applied in the direction of silica, silicon oxide, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Accurate 1.78mol H 2 O, 1 mol absolute ethanol, 0.36 mol tetrapropylene hydroxide, 0.002 molnaOH, 43ml silica sol (30%, containing 2.24 mol h 2 O and 0.26mol SiO 2 Stirring, mixed under room temperature conditions, continuous reflow treatment under 80 ° C, and the treatment time is 216 h. The mixture was filtered, and the deionized water was washed 5 times, and 530 ° C in the muffer was 830 ° C for 3 h, and the temperature increase rate was 1 ° C / min, and 1 # sample was obtained.

Embodiment 2

[0028] Accurate 1.67mol H 2 O, 0.93 mol absolute ethanol, 0.33 mol tetraproprioxide, 0.0018 gnOH, 38.5 ml silica sol (30%, containing 2.0 mol h 2 O and 0.23mol Sio 2 Stir, mixed under room temperature, continuous reflow treatment under 80 ° C, and the treatment time was 72 h, and the mixture was transferred to the autoclave and placed at 85 ° C for 72 h. The post mixture was filtered, and the deionized water was washed 5 times, and 550 ° C in the muffle furnace was held for 3 h, and the water temperature rate was 1 ° C / min, and the 2 # sample was obtained after cooling.

Embodiment 3

[0030] Accurate 1.78mol H 2 O, 1 mol absolute ethanol, 0.36 mol tetrapropylene hydroxide, 0.002 molnaOH, 43ml silica sol (30%, containing 2.24 mol h 2 O and 0.26mol SiO 2 Stirring, mixed under room temperature, continuous reflow treatment under 80 ° C, and the treatment time was transferred to the autoclave to the autoclave and placed at 90 ° C for 60 hours. The post mixture was filtered, 550 ° C in the muffle in the muffle was 10 h, and the water temperature rate was 1 ° C / min, and the 3 # sample was obtained after cooling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Bet specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com