Preparation method of aliphatic polycarbonate polyester copolymer with zero addition of catalyst

A polycarbonate polyester and copolymer technology, applied in the field of material science, can solve the problems of unassessable safety of small-molecule organics, high toxicity of catalysts, etc., achieve huge application transformation potential, simple and efficient preparation method, and simple preparation steps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The reaction formula prepared by aliphatic polycarbonate polyester copolymer is as follows:

[0050]

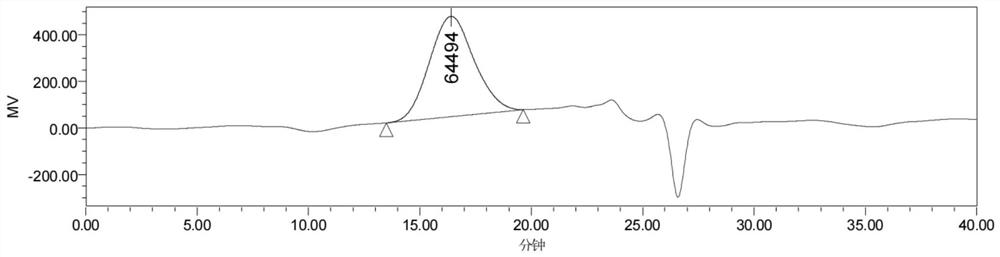

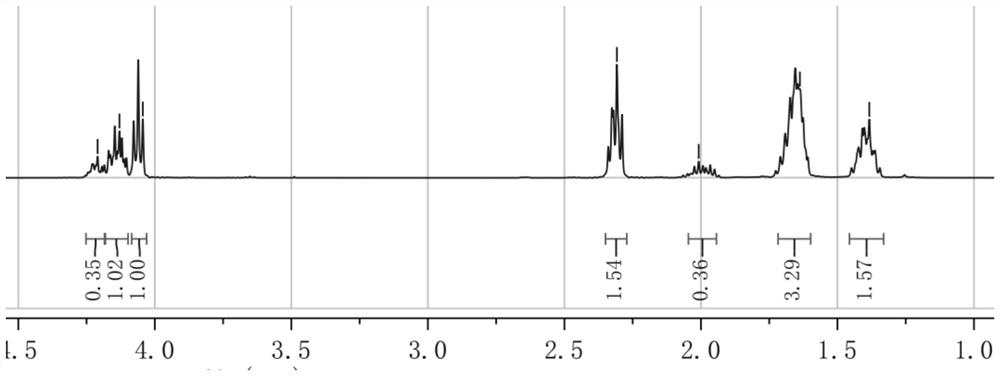

[0051] The preparation of aliphatic polycarbonate polyester copolymer specifically includes the steps of: weighing 0.15 gram of six-membered ring carbonate [specifically trimethylene carbonate (abbreviated as TMC)] and 0.15 cyclic lactone [specifically ε-hexyl Lactone (abbreviated as CL)] was added into a decompressible airtight container, dried in vacuum for 0.5 hour, and sealed under negative pressure. Under magnetic stirring, the reaction vessel was placed in an oil bath at 100° C. for 7 hours, and the polymerization was completed. The product was dissolved in 2mL of dichloromethane and dropped into 40mL of methanol to obtain a white precipitate. The methanol was poured while washing the product 2 times with clean methanol. After drying, an aliphatic polycarbonate polyester copolymer is obtained, whose structural formula is Weigh, calculate productive rate, p...

Embodiment 2

[0054] The reaction formula that aliphatic polycarbonate polyester copolymer prepares is with embodiment 1, and the preparation of aliphatic polycarbonate polyester copolymer specifically comprises the steps:

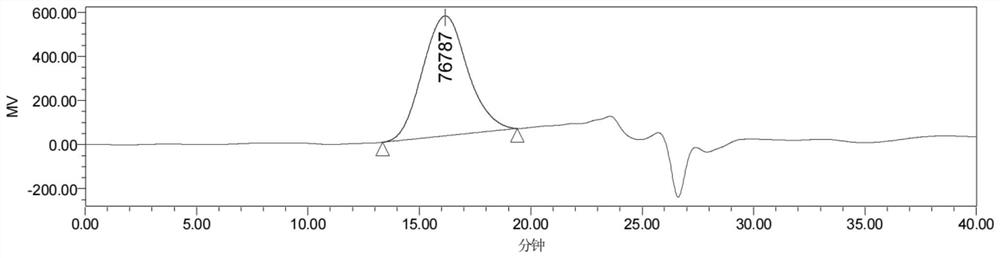

[0055] Weigh 0.15 g of six-membered ring carbonate [specifically trimethylene carbonate (abbreviated as TMC)] and 0.15 cyclic lactone [specifically ε-caprolactone (abbreviated as CL)] and add it to a decompressible airtight container, Vacuum dry for 0.5 hours, and seal under negative pressure. Under magnetic stirring, the reaction vessel was placed in an oil bath at 120° C. for 7 hours, and the polymerization was completed. The product was dissolved in 2mL of dichloromethane and dropped into 40mL of methanol to obtain a white precipitate. The methanol was poured while washing the product 2 times with clean methanol. After drying, an aliphatic polycarbonate is obtained, whose structural formula is Weigh, calculate productive rate, productive rate is 38%. GPC (THF as...

Embodiment 3

[0057] The reaction formula that aliphatic polycarbonate polyester copolymer prepares is with embodiment 1, and the preparation of aliphatic polycarbonate polyester copolymer specifically comprises the steps:

[0058] Weigh 0.15 g of six-membered ring carbonate [specifically trimethylene carbonate (abbreviated as TMC)] and 0.15 cyclic lactone [specifically ε-caprolactone (abbreviated as CL)] and add it to a decompressible airtight container, Vacuum dry for 0.5 hours, and seal under negative pressure. Under magnetic stirring, the reaction vessel was placed in an oil bath at 140° C. for 7 hours, and the polymerization was completed. The product was dissolved in 2mL of dichloromethane and dropped into 40mL of methanol to obtain a white precipitate. The methanol was poured while washing the product 2 times with clean methanol. After drying, an aliphatic polycarbonate is obtained, whose structural formula is Weigh, calculate productive rate, productive rate is 41%. GPC (THF as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| number average molecular weight | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com