Electronic tray and preparation method thereof

An electronic tray and silicone technology, applied in the field of plastic products, can solve the problems of reducing the surface gloss of the tray and increasing the production cost, and achieve the effects of excellent wear resistance, improved adhesion and wear resistance, and high bonding strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A kind of electronic pallet, is made up of substrate and the matte ink that is printed on the surface of substrate, and each component and its corresponding weight in substrate are shown in Table 1, and each component and its corresponding weight in matte ink are as shown in Table 1. Table 2 shows. The electronic tray is prepared through the following steps:

[0048]S1. Mix polyethylene terephthalate, talcum powder, dialkyldiphenylamine, and SBS toughening agent evenly, and then put them into a twin-screw extruder for extrusion molding. The temperature of the twin-screw extruder is controlled by The temperature from the inlet to the outlet is controlled to 195°C, 205°C, 215°C, 225°C, and 235°C in sequence to obtain the membrane material;

[0049] S2. Through the plastic forming equipment, at a temperature of 160 ° C, the extruded film material is hot-melted and covered on the template, and the film material is crimped, vacuum-absorbed, and cut after cooling to obtain a...

Embodiment 2-6

[0055] An electronic tray, the difference from Example 1 is that each component and its corresponding weight are shown in Table 1.

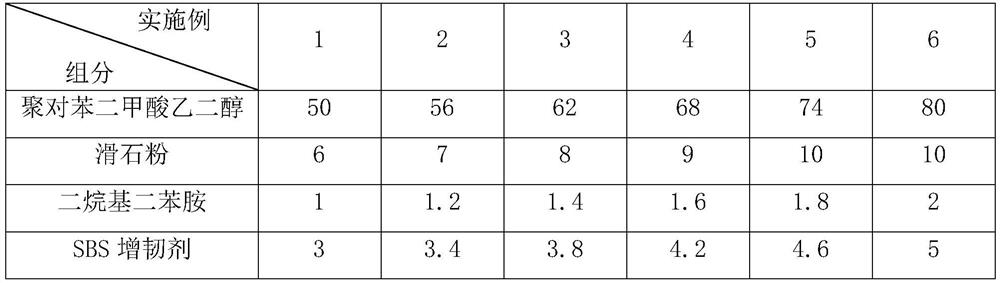

[0056] Each component of base material and its weight (kg) in table 1 embodiment 1-6

[0057]

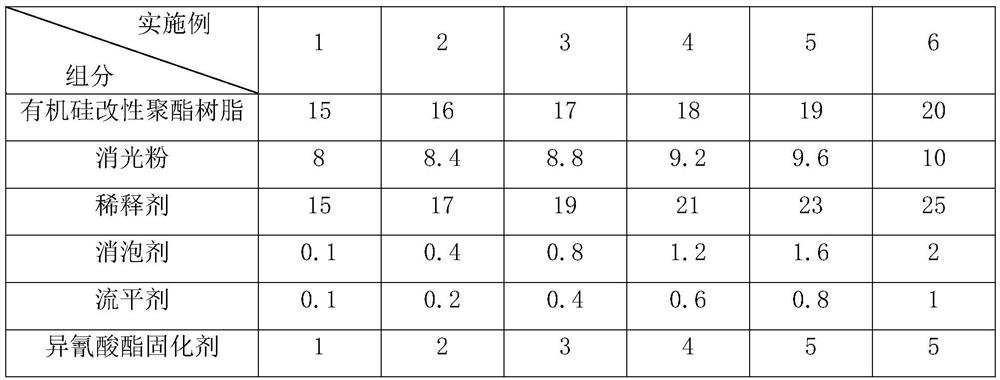

[0058] Each component of matte ink and its weight (kg) in table 2 embodiment 1-6

[0059]

Embodiment 7

[0061] An electronic tray, the difference from Example 1 is that the organosilicon-modified polyester resin is prepared by polycondensation reaction of organosilicon resin and polyester resin, and the mass ratio of the organosilicon resin to polyester resin is 1:0.2.

[0062] Silica is used as the matting powder, and a mixture of ethyl acetate and butanone is used as the diluent, and the weight ratio of ethyl acetate and butanone is 1:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| loss value | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com