Glaze composition, glaze and preparation method thereof, ceramic tile and preparation method thereof

A composition and ceramic tile technology, applied in the field of ceramics, can solve the problems of high control difficulty, high labor cost, large equipment investment, etc., and achieve the effects of low operation difficulty, low production cost, and reduced material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

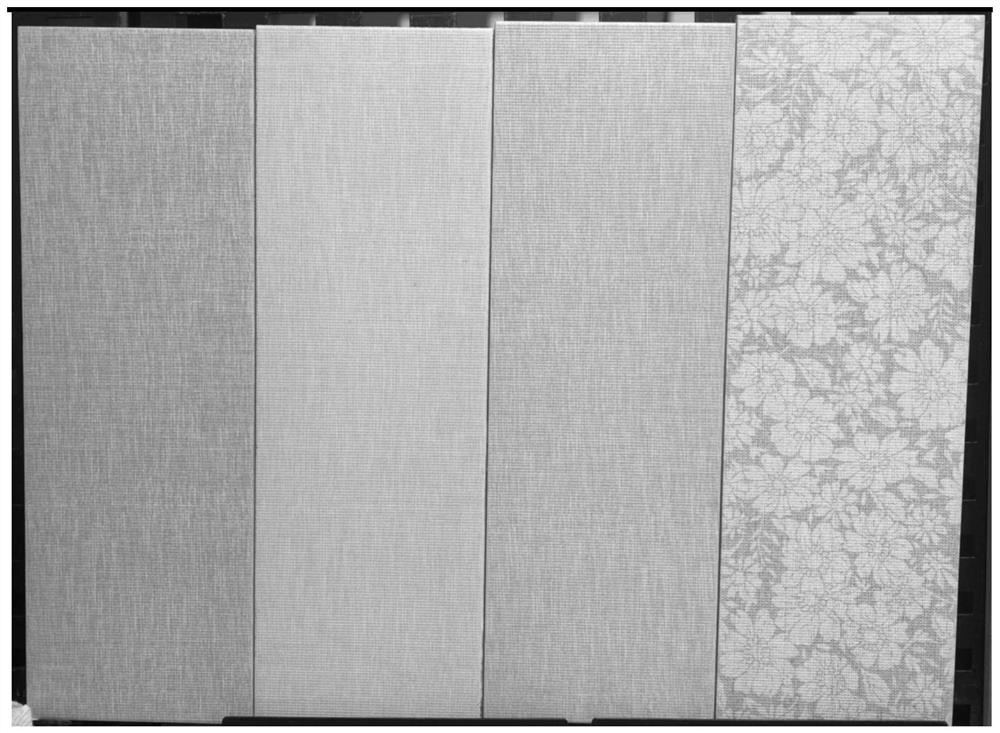

Image

Examples

Embodiment 1

[0062] This embodiment provides a glaze composition, including: 27kg of zirconium white frit, 5kg of quartz stone, 5kg of wollastonite, 23kg of matt frit, 10kg of washed kaolin, 7kg of calcined kaolin, and 23kg of zirconium silicate.

[0063] The above raw materials were mixed and then ball-milled for 4 hours, and then discharged after the fineness was detected.

[0064] A finely carved mold is obtained by four-dimensional laser engraving, and the diameter of the light source for four-dimensional laser engraving is 0.02 mm. Then, an isostatic pressing die press is used to press under the condition of 24000KN to obtain a brick blank, and the thickness of the brick blank is 9.2mm.

[0065] The above bricks were fired at 942° C. for 45 minutes, and then cooled to room temperature.

[0066] Transfer the prepared glaze to the glaze spraying room, pass through a 325-mesh sieve, the sieve residue is 0.6wt%, add 38kg of water after sieving to obtain the glaze, and control the specifi...

Embodiment 2

[0070] This embodiment provides a glaze composition, which is composed of the following raw materials: 25kg of zirconium white frit, 4kg of quartz stone, 7kg of wollastonite, 22.3kg of matt frit, 10kg of washed kaolin, 6kg of calcined kaolin, and 25kg of zirconium silicate , 0.2kg of sodium tripolyphosphate and 0.5kg of sodium carboxymethyl cellulose.

[0071] The above raw materials were mixed and then ball-milled for 5 hours, and then discharged after the fineness was detected.

[0072] A finely carved mold is obtained by four-dimensional laser engraving, and the diameter of the light source for four-dimensional laser engraving is 0.03 mm. Then, using an isostatic pressing die press, press under the condition of 26000KN to obtain adobe, and the thickness of the adobe is 9.5mm.

[0073] The above bricks were fired at 1125°C for 40 minutes, and then cooled to room temperature.

[0074] Transfer the prepared glaze to the spraying room, pass through a 325-mesh sieve, the sieve...

Embodiment 3

[0078] This embodiment provides a glaze composition, comprising: 26.5kg of zirconium white frit, 3.5kg of quartz stone, 6.55kg of wollastonite, 21.5kg of matte frit, 10kg of washed kaolin, 7kg of calcined kaolin, and 24.5kg of zirconium silicate. kg, sodium tripolyphosphate 0.15kg and sodium carboxymethyl cellulose 0.3kg.

[0079] After mixing the above raw materials, ball mill for 4.5 hours, and then discharge the material after testing the fineness.

[0080] A finely carved mold is obtained by four-dimensional laser engraving, and the diameter of the light source for four-dimensional laser engraving is 0.04 mm. Then, an isostatic pressing die press was used to press under the condition of 25000KN to obtain a brick blank, and the thickness of the brick blank was 9.3mm.

[0081] The above bricks were fired at 1100°C for 42 minutes, and then cooled to room temperature.

[0082] Transfer the prepared glaze to the spraying room, pass through a 325 mesh sieve, the sieve residue ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com