Special sweet orange essence for electronic atomized liquid and preparation method of special sweet orange essence

A sweet orange essence, electronic atomization technology, applied in chemical instruments and methods, dissolution methods, essential oils/spice, etc., can solve the problems of poor taste of electronic atomization liquid, and achieve the effect of good taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

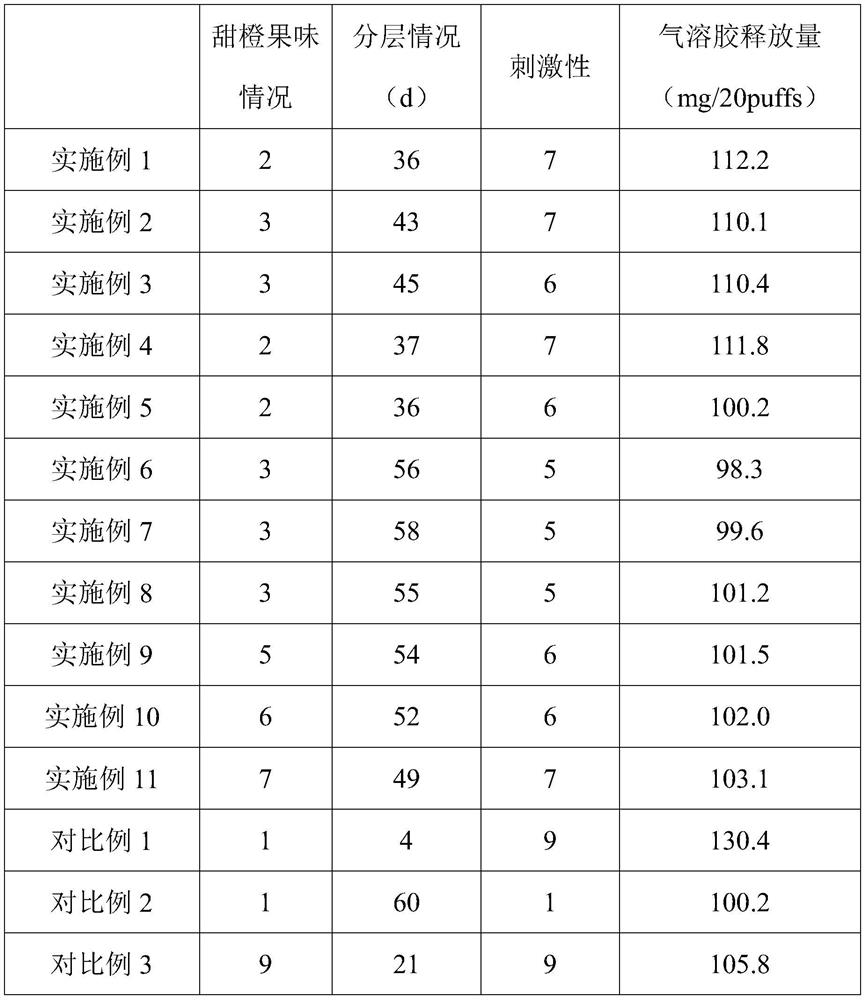

Examples

preparation example 1

[0037] A kind of purified sweet orange oil, its preparation steps are as follows:

[0038] 1) Add 7kg of ethanol to 10kg of sweet orange oil, stir evenly, then add 2kg of distilled water, stir while adding, and then stand for stratification for 75h, separate liquid, remove the upper layer, and obtain a solution A;

[0039] 2) The solution A is concentrated by rotary evaporation, and the solvent is removed to obtain purified sweet orange oil.

preparation example 2

[0041] A kind of purified sweet orange oil, its preparation steps are as follows:

[0042] 1) Add 11kg of ethanol to 15kg of sweet orange oil, stir evenly, then add 4kg of distilled water, stir while adding, then let stand for 70 hours, separate the liquid, remove the upper layer, and get the solution A;

[0043] 2) The solution A is concentrated by rotary evaporation, and the solvent is removed to obtain purified sweet orange oil.

preparation example 3

[0045] A kind of sweet orange oil of purification, and the difference of preparation example 2 is that its step 1) concrete operation is as follows:

[0046] Add 11kg of mixed solution of ethanol, butanediol and ether to 15kg of sweet orange oil, wherein the weight ratio of ethanol, butanediol and ether is 5:1:3, stir evenly, and then add 4kg of distilled water , Stirring while adding, and then standing for 70h to separate the layers, and remove the upper layer to obtain solution A.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com