Petroleum distillation tower cleaning agent

A technology of distillation tower and cleaning agent, which is applied in the direction of detergent composition, soap detergent composition, surface active detergent composition, etc., to achieve excellent anti-rust effect, no toxic side effects, and high cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

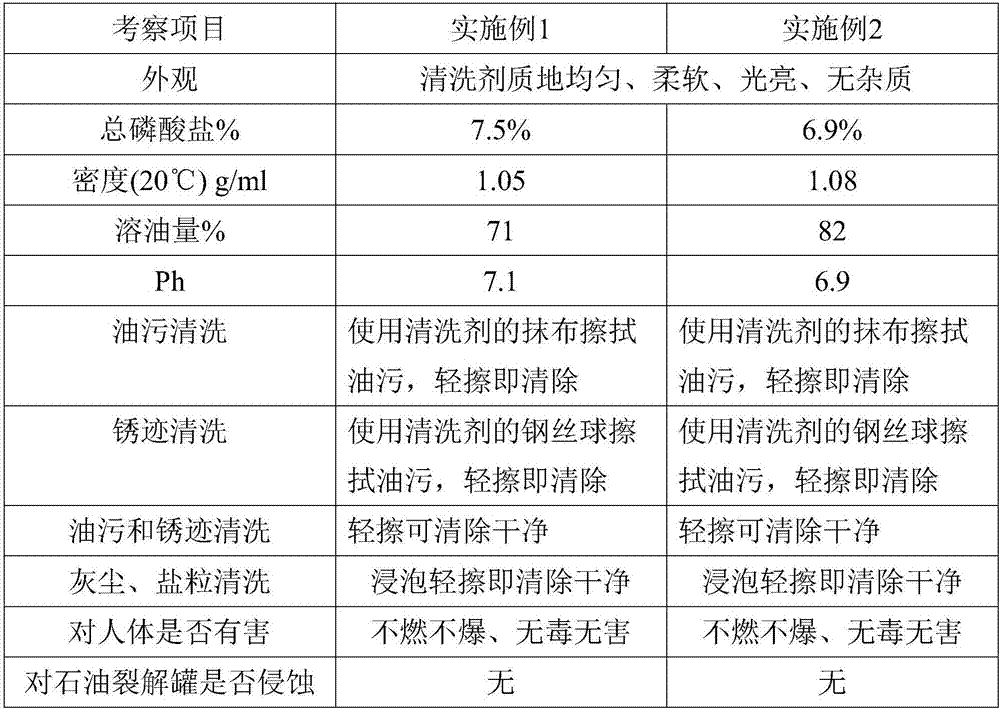

Examples

Embodiment 1

[0019] A petroleum rectification tower cleaning agent is made of the following raw material components in parts by weight:

[0020] 10 parts of attapulgite, 10 parts of charcoal ash, 6 parts of grape seed oil, 6 parts of turpentine oil, 8 parts of standing paraffin, 5 parts of trisodium phosphate, 4 parts of sodium metasilicate, 5 parts of sodium hydroxide, 3 parts of walnut shell powder 5 parts, N, N-bishydroxyethyl coconut oil amide, 2 parts of drawing powder, 2 parts of sodium sulfate ether, 2 parts of sea sand powder, 5 parts of active agent, 5 parts of active auxiliary agent, 2 parts of defoamer, 5 parts of ethanol, 10 parts of deionized water.

[0021] The preparation method of the walnut shell powder is as follows: collect the walnut shells, put the walnut shells into warm alkaline water and soak for 2 hours, the pH of the warm alkaline water is 7.5, and when the walnut shells are soft, take them out and put them into a grinder, and the crushed particles have a size of ...

Embodiment 2

[0031] A petroleum rectification tower cleaning agent, made of the following raw material components in parts by weight: 20 parts of attapulgite, 20 parts of charcoal ash, 20 parts of grape seed oil, 10 parts of turpentine, 5 parts of paraffin wax, trisodium phosphate 10 parts, 6 parts of sodium metasilicate, 5 parts of sodium hydroxide, 7 parts of walnut shell powder, 5 parts of N, N-bishydroxyethyl coconut oil amide, 8 parts of drawing powder, 2 parts of sodium sulfate ether, sea sand Powder 2 parts, active agent 5 parts, active auxiliary agent 5 parts, defoamer 2 parts, ethanol 5 parts, deionized water 20 parts.

[0032] The preparation method of the walnut shell powder is as follows: collect walnut shells, put the walnut shells into warm alkaline water and soak for 6 hours, the pH of the warm alkaline water is 8.0, and when the walnut shells are soft, take them out and put them into a grinder, and the crushed particles have a size of 0.1-1mm, after passing through a 40-mes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com