Leclercia adcarboxglata NJ22 taking lactic acid as carbon source and application of Leclercia adcarboxglata NJ22

A technology of non-decarboxylated Lucka, NJ22, applied in the field of microorganisms, can solve the problems of reducing the quality of liquor, suppressing the main aroma, and increasing the content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1 of the present invention: Isolation and Identification of Lactic Acid Utilizing Bacteria NJ22

[0018] (1) Isolation and Screening of Lactic Acid Utilizing Bacteria NJ22

[0019] Weigh 1g of the pit mud sample and add it to the improved Lu-Ye liquid medium (lactic acid 1g / L; (NH4)2SO4 2g / L; Na2HPO4·12H2O 14.3g / L; KH2PO4 3g / L; MnSO4·H2O 0.28mg / L; FeSO4·7H2O 0.3mg / L; MgSO4·7H2O 0.06mg / L; CaCl2 1mg / L; CuSO4 0.05mg / L; H3BO3 0.05mg / L), static culture for 48h to enrich the lactic acid utilization bacteria; Dilute the bacteria collection solution step by step, choose 10-1, 10-2, 10-3 three concentration gradients, draw 100uL of the dilution, and spread it on the improved Lu-Ye solid medium; place the culture dish upside down in the incubator Medium culture, 32 ℃, 3 to 5 days.

[0020] (2) Purification

[0021] Pick a single colony on a petri dish, and purify it on the modified Lu-Ye medium by the three-streak method. After three consecutive purifications, a pure s...

Embodiment 2

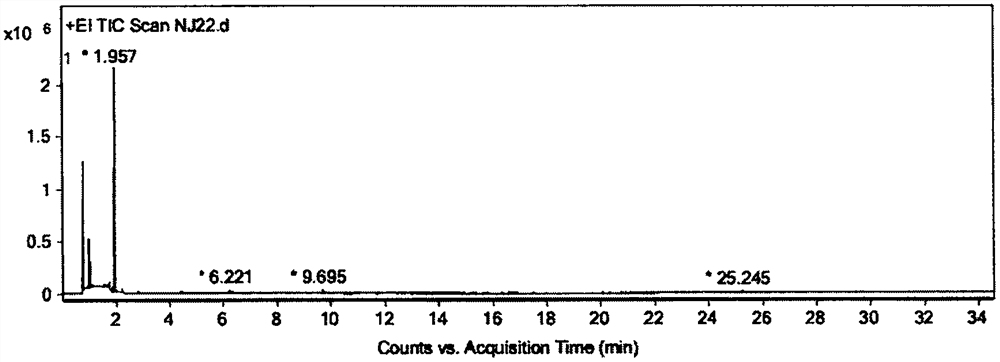

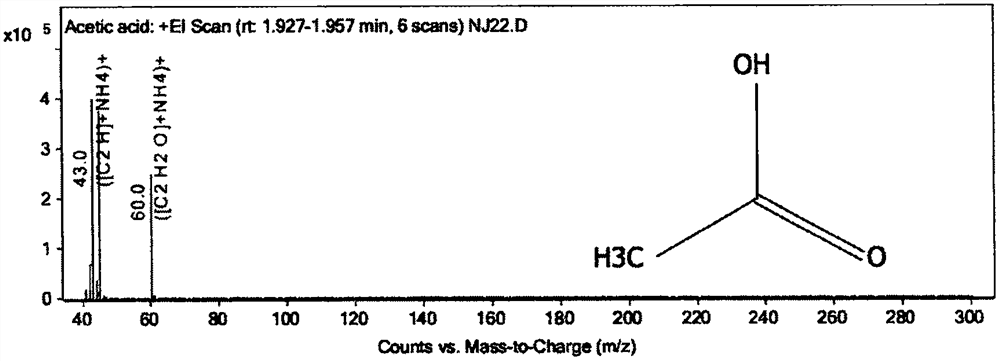

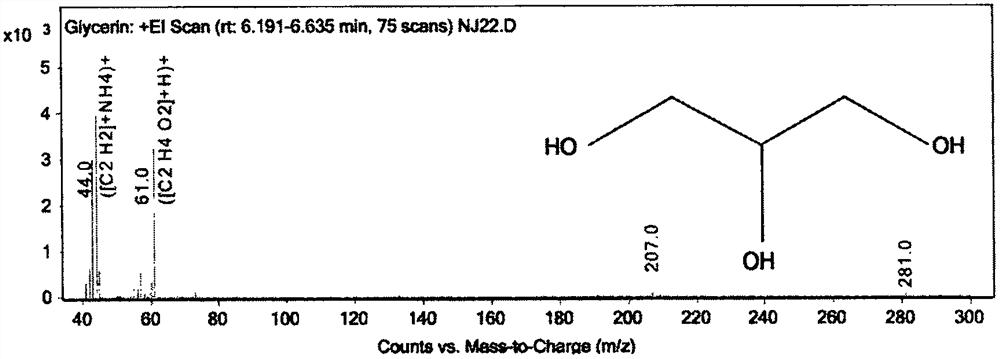

[0038] Embodiment 2 of the present invention: utilize lactic acid to carry out fermentation, the detection of fermentation product

[0039] Specific steps:

[0040] (1) Inoculate the non-decarboxylated Luxella NJ22 into the modified Lu-Ye liquid medium and culture at 30°C for 72h

[0041] (2) Centrifuge, discard the bacteria, and leave the supernatant

[0042] (3) Filter the supernatant with a 0.22 μm microporous membrane to remove bacteria.

[0043] (4) The sample is subjected to chromatographic mass spectrometry analysis, and the analysis and detection conditions are:

[0044] Chromatographic column: Agilent DB-5 30m*0.32mm, 0.25um

[0045] Carrier gas: helium, flow rate: 1.8ml / min, split ratio = 5:1

[0046] Heating program: 40°C, keep 4min; 10°C / min rise to 100°C, keep 0min; 25°C / min rise to 200°C, keep 0min.

[0047] Front inlet temperature: 150°C

[0048] Ion source temperature: 230°C

[0049] Quadrupole temperature: 150°C

[0050] Injection volume: 1μL

[0051]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com