Thin spinning metering pump

A metering pump and spinning technology, which is applied in the field of spinning machinery and equipment, can solve the problems of high material consumption, large thickness of the metering pump, and difficult processing of the metering pump.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

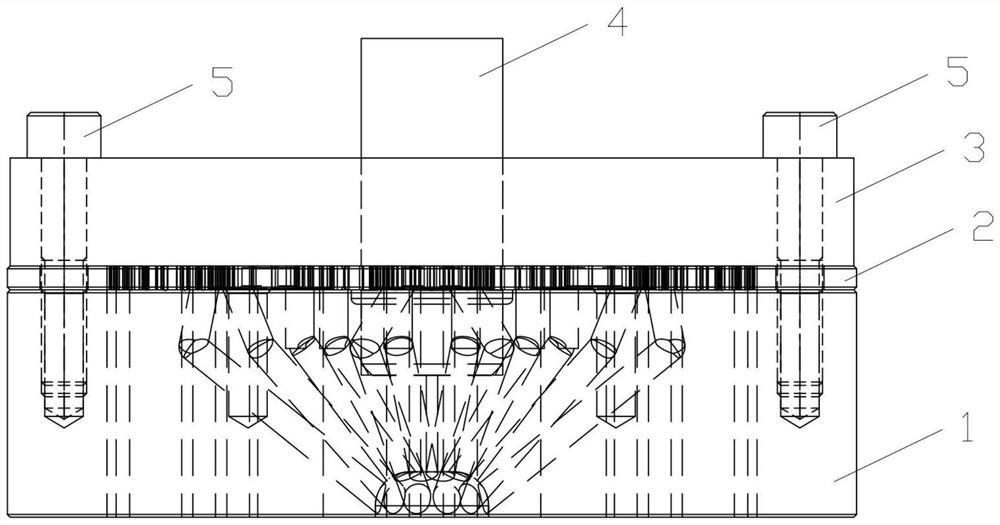

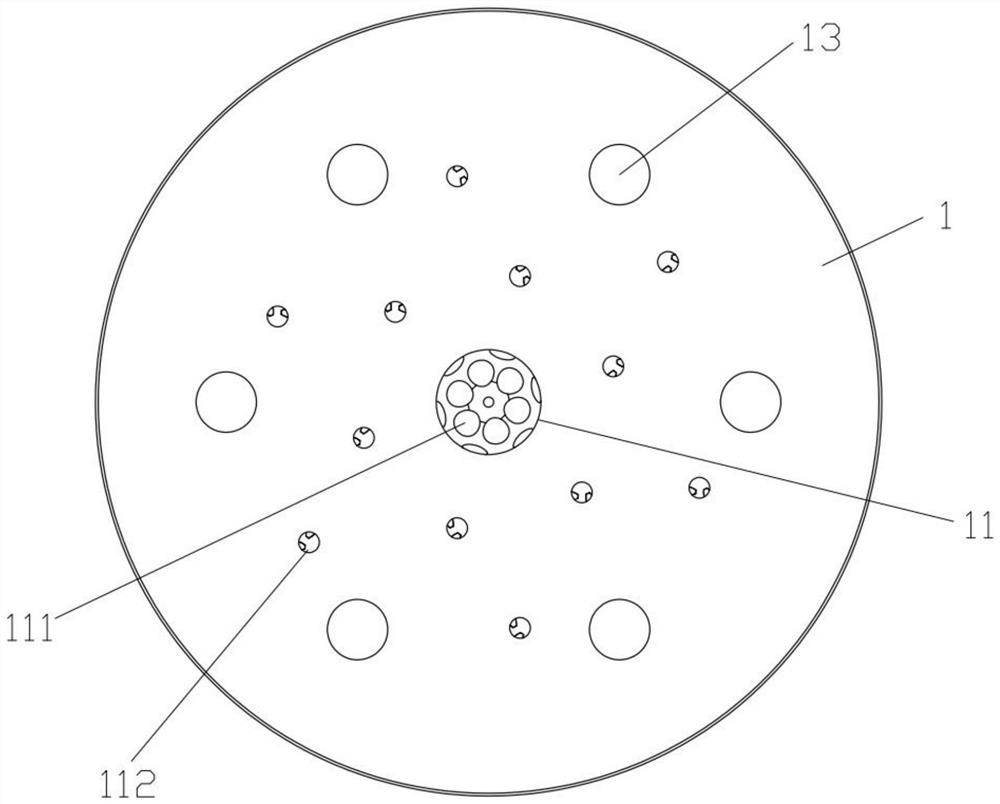

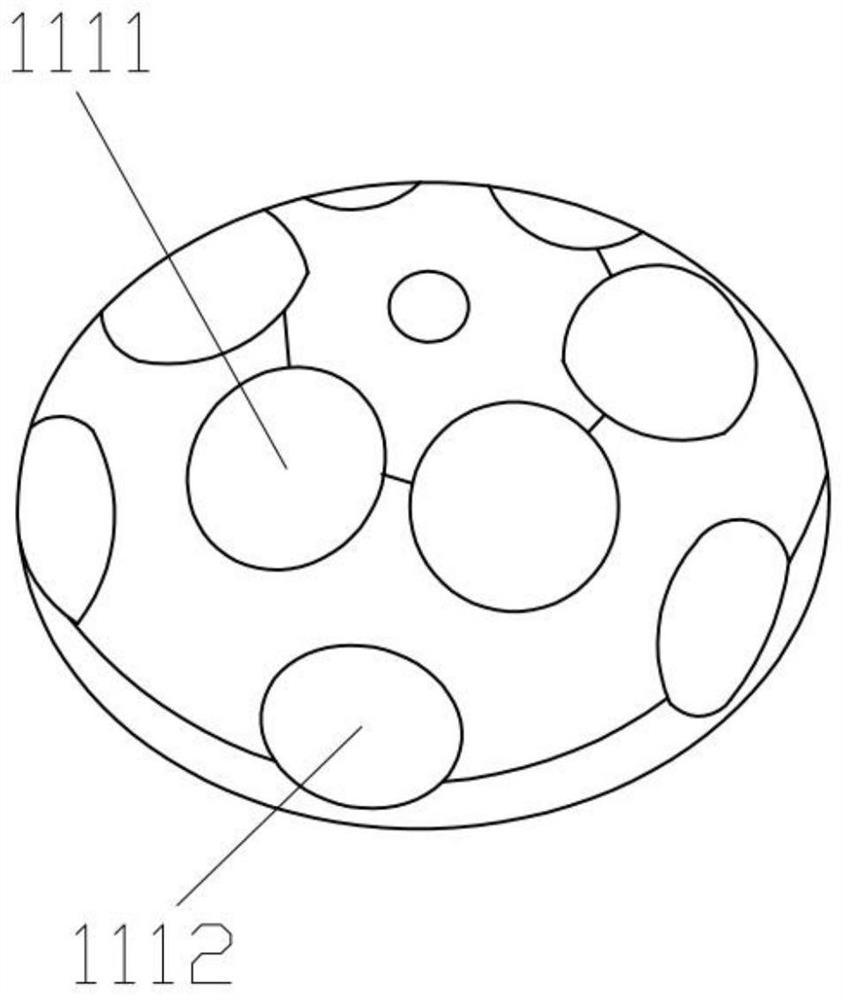

[0039] Such as Figure 1-8 The overall and partial structure schematic diagram of the thin spinning metering pump is given.

[0040] In this embodiment 1, the thin spinning metering pump has a structure of 1 in and 12 out, that is, the metering pump includes 1 polymer solution or polymer melt inlet, and 12 polymer solution or polymer melt inlets. Body outlet.

[0041] The thin spinning metering pump includes a pump plate 1, a gear plate 2, a cover plate 3, and a drive shaft 4 that runs through the cover plate 3 and the gear plate 2 from bottom to top, such as figure 1 As shown, it is a schematic diagram of the assembled structure of the pump plate 1, the gear plate 2 and the cover plate 3. The pump plate 1, the gear plate 2 and the cover plate 3 are detachably connected, specifically connected together by fastening screws 5, The drive shaft 4 is located at the center of the metering pump. The pump plate 1, the gear plate 2 and the cover plate 3 are all cylindrical structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com