Dual-wavelength dual-confocal laser microscopic measurement device and measurement method

A microscopic measurement and dual-wavelength technology, applied in measuring devices, material analysis through optical means, instruments, etc., can solve the problems of large loss of lateral resolution of the system, complex optical path of the imaging system, and low lateral resolution, and achieve Improved axial resolution, suppression of sidelobe noise, and improved signal-to-noise ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing.

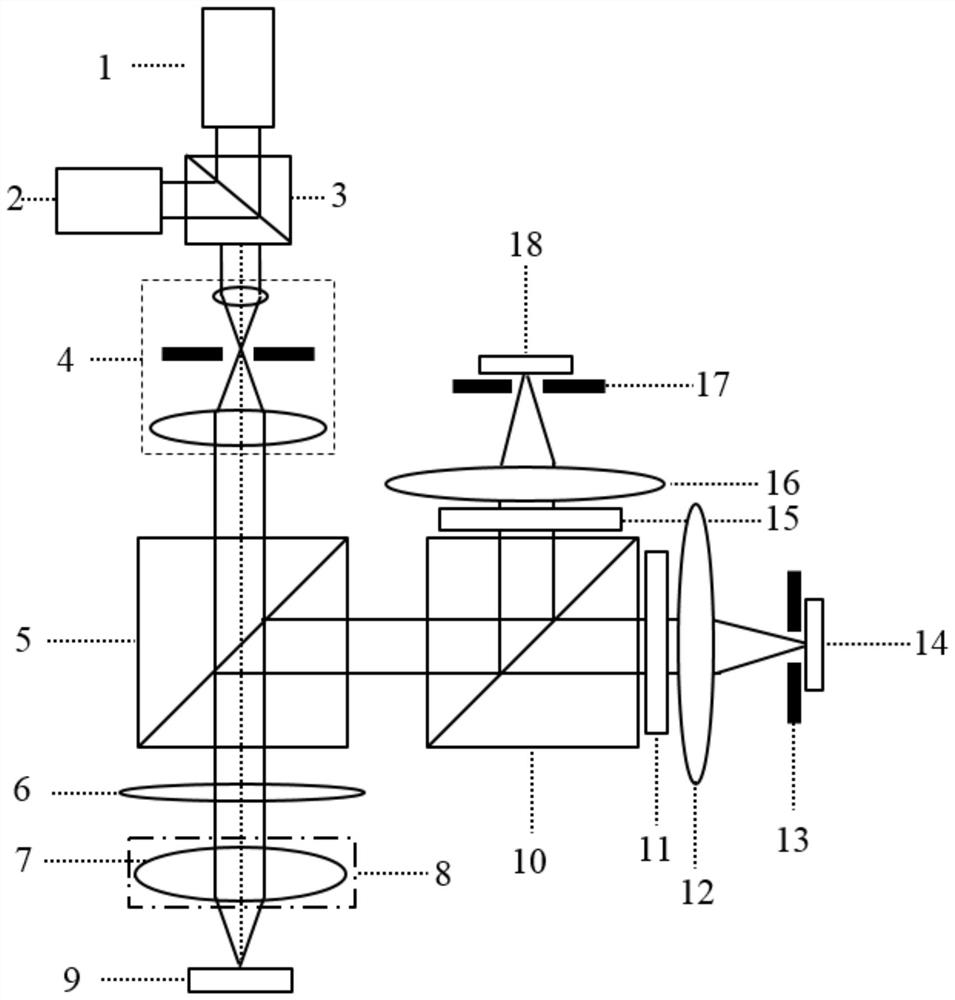

[0024] like figure 1 As shown, the dual-wavelength dual confocal laser microscopic measurement device of the present invention includes a laser, an incident light path, a reflection light path and a detection device. The laser includes a laser I1 and a laser II2, and the incident light path is: the two incident beam directions of the beam splitter 3 The laser I1 and the laser II2 are set respectively, and the direction of the outgoing beam of the beam splitter 3 is sequentially set with the collimator 4, the polarizing beam splitter 5, the quarter slide 6, the objective lens 7 and the sample stage 9, and the laser I1 and the laser II2 respectively emit Two laser beams with different wavelengths, for example, the incident directions of laser I1 and laser II2 are perpendicular to each other, and the laser beam passes through beam splitter 3, collimator 4, polarizing beam spli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com