A kind of hemispherical microlens and preparation method thereof

A microlens and hemispherical technology, applied in the fields of optics and electronics, can solve the problems of large half-width of the focused beam beam, low light intensity, short working distance of the microsphere lens, etc., and achieve the goal of reducing the half-width and having a large market prospect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

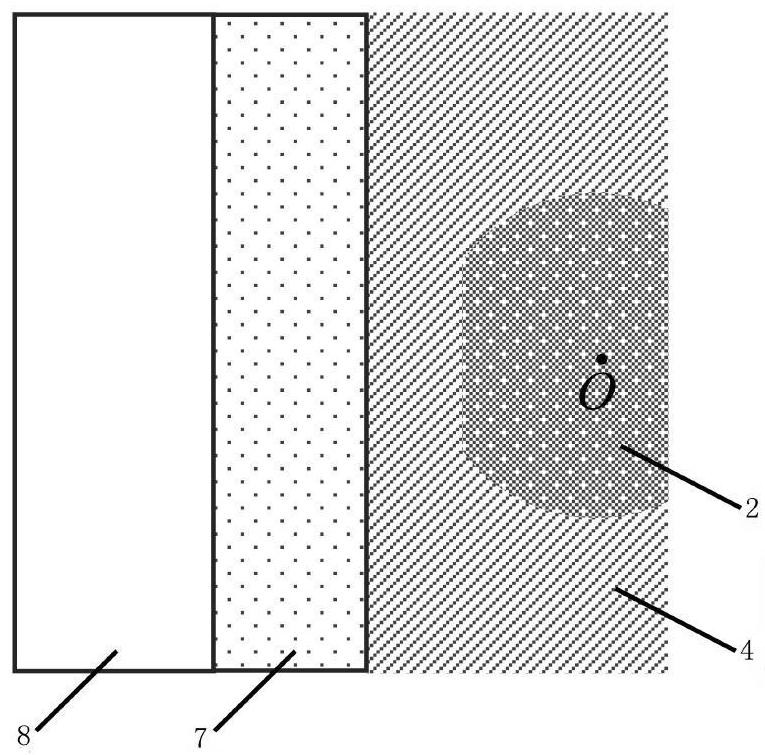

[0034] Such as figure 2 Shown, a kind of hemispherical microlens comprises at least one lens body 2, and described lens body 2 is: selected standard microsphere lens 2 ' a surface passing through the center of the sphere, on the surface passing through the center of the sphere Part of the spherical surface is cut off in parallel on both sides.

[0035] Further, it also includes a second material film layer 4, the lens body 2 is soaked in the second material film layer 4, a cut surface of the lens body 2 is located on the surface of the second material film layer 4, and the second material can also be made The surface of the film layer (4) is higher than the cut plane of the lens body (2).

[0036] The working principle of the hemispherical microlens in the present invention is: its part of the spherical surface is cut and removed by a plane parallel to the plane of the hemispherical microlens, and then soaked in the material film layer, when the incident light parallel to th...

Embodiment 2

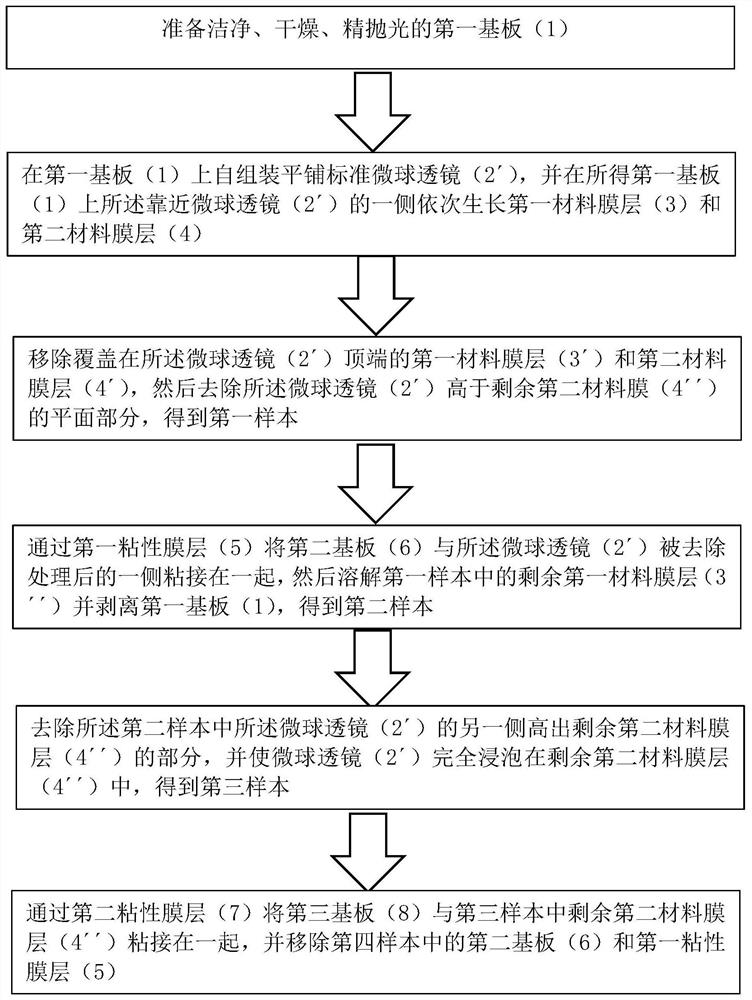

[0042] In this embodiment, a kind of preparation method of the soaked hemispherical microlens is provided, such as figure 1 As shown, the method includes the following steps:

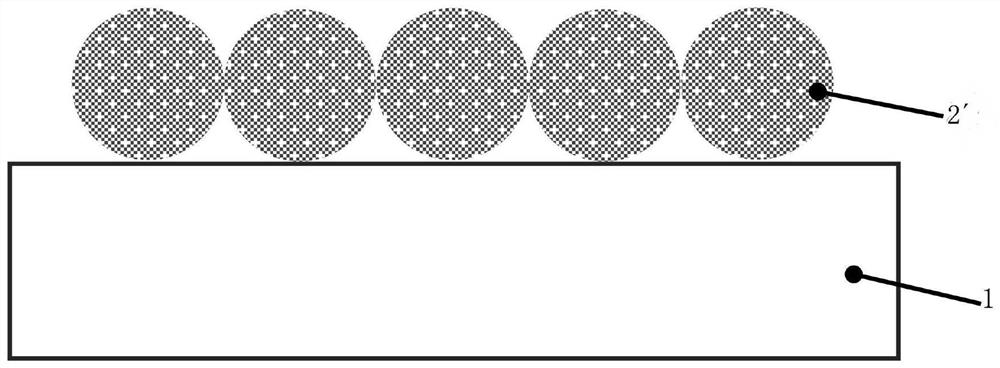

[0043] S1. If image 3 , 4 As shown, the self-assembled flat standard microsphere lens 2' is self-assembled on the first substrate 1, and the first material film layer 3 and the second material film layer 3 are sequentially grown on the obtained first substrate 1 on the side close to the microsphere lens 2'. Material film layer 4;

[0044] S2. If Figure 5 , 6 As shown, remove the first material film layer 3' and the second material film layer 4' covering the top of the microsphere lens 2', and then remove the remaining second material film 4" higher than the microsphere lens 2' The plane part of , get the first sample;

[0045] S3. If Figure 7 , 8 As shown, through the first adhesive film layer 5, the second substrate 6 and the side of the microsphere lens 2′ after the removal process are bond...

Embodiment 3

[0056] In an exemplary embodiment, a method of preparing a soaked hemispherical microlens comprises the steps of:

[0057] (1) Prepare a clean, dry, double-sided precision polished quartz plate, the size is: 15mm*15mm.

[0058] (2) A certain polished surface of the quartz plate prepared in (1) is tiled to obtain a single-layer microsphere lens array through the gas-liquid interface self-assembly method. The rate is 1.55.

[0059] (3) Copper and magnesium fluoride are vertically grown on one side of the quartz plate in (2) by the electron beam evaporation coating method, the growth rate is about 0.5nm / s, the thickness of the copper film is 2000nm, and the thickness of magnesium fluoride is 2500nm, the total thickness is 4500nm.

[0060] (4) Combining ultrasonic cleaning and mechanical peeling (blue film tape peeling) to remove the magnesium fluoride above the sample microspheres obtained in (3).

[0061] (5) Put the sample piece obtained in (4) into an oven horizontally, set...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com