Method for testing performance of fire-resistant thermal insulation material

A technology of refractory heat preservation and testing methods, applied in the direction of material thermal development, etc., can solve the problems of high sample requirements, complicated testing process, poor repeatability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

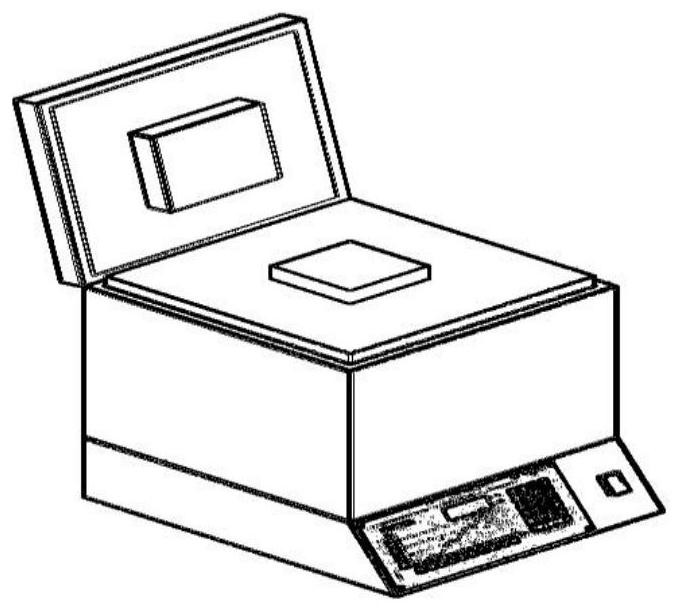

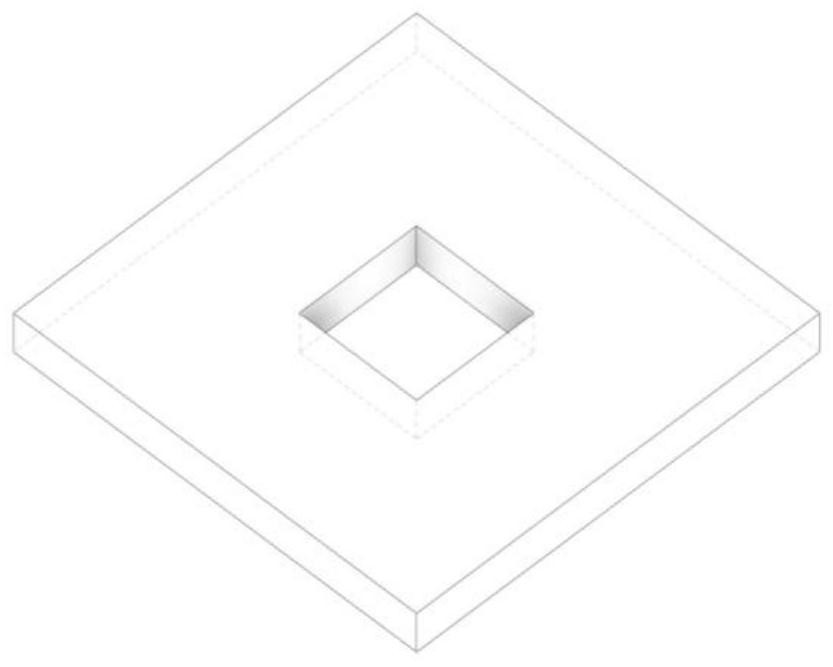

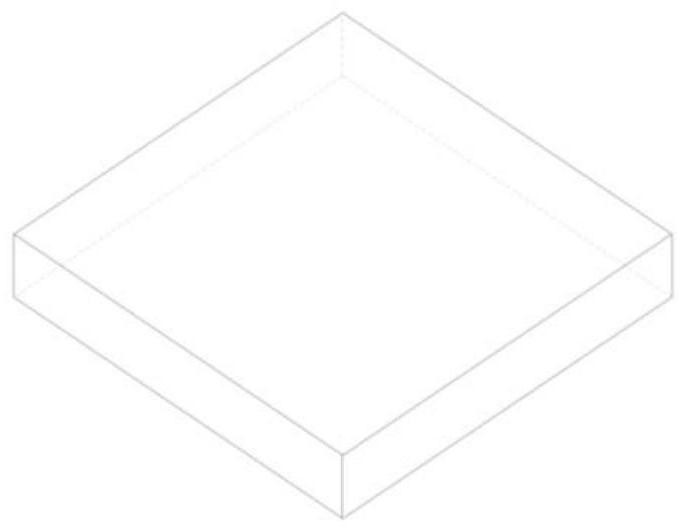

[0026] Cut the refractory insulation material 4 used in the cement plant into samples with a length and width of 170×170 mm, and dry them in a thermostat. Place the sample on the electric furnace. The size of the furnace mouth 2 is 150×150mm. There is no insulation partition on the electric furnace. The sample is surrounded by the thermal insulation material 3 with a thermal conductivity of 0.025w / (m·K) and the same height. The insulation material 3 is wrapped to the outer edge 1 of the electric furnace, and the center of the sample is used as a point to draw grid line points. The area of the grid line is 40×40mm. The electric furnace is heated to 400°C, and the initial time interval is 1h. The temperature value on the grid line, and calculate the average temperature of the intersection point of the sample grid line as the average temperature of the sample surface. When the average temperature tends to be stable, continue to record every 10 minutes. When the average temperat...

Embodiment 2

[0029] Cut the refractory insulation material 4 used by the manufacturer with a length and width of 100×100 mm into samples, and dry them in a thermostat. The sample is placed on the electric furnace. The size of the furnace mouth 2 is 150×150mm. The electric furnace is equipped with a thermal insulation partition, and the thermal insulation partition is an alumina fiber board. The vertical and horizontal centerlines of the sample, insulation partition and furnace mouth coincide. The sample is surrounded by thermal insulation material 3 of the same height with a thermal conductivity of 0.03w / (m·K), and the thermal insulation material 3 is wrapped to the outer edge 1 of the electric furnace. Take the center of the sample as a point, draw grid line points, and the area of the grid line is 25×25mm. Heat the electric furnace to 850°C, record the temperature value of the intersection point on the grid line of the sample surface at an initial time interval of 1h, and calculate th...

Embodiment 3

[0033] The Simo red refractory brick sample sent by the cement factory is placed on the electric furnace. The size of the furnace mouth 2 is 150×150mm. The electric furnace is equipped with a thermal insulation partition, and the thermal insulation partition is an alumina fiber board. The vertical and horizontal centerlines of refractory bricks, insulation partitions and furnace mouth coincide. The sample is surrounded by thermal insulation material 3 with a thermal conductivity of 0.025w / (m·K) at the same height, and the thermal insulation material 3 is wrapped to the outer edge 1 of the electric furnace. Take the center of the sample as a point, draw grid line points, and the area of the grid line is 20×100mm. Heat the electric furnace to 1200°C, record the temperature value of the intersection point on the grid line of the sample surface at an initial time interval of 1h, and calculate the average temperature of the sample grid line as the average temperature of the sampl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com