Proton exchange membrane applied to fuel cell and preparation method of proton exchange membrane

A proton exchange membrane, fuel cell technology, applied in fuel cells, circuits, electrical components, etc., can solve problems such as performance that has not yet been reported, and achieve the effects of good transmission pathways, high proton conductivity, and good water retention performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] MsACT 0.5 Preparation of:

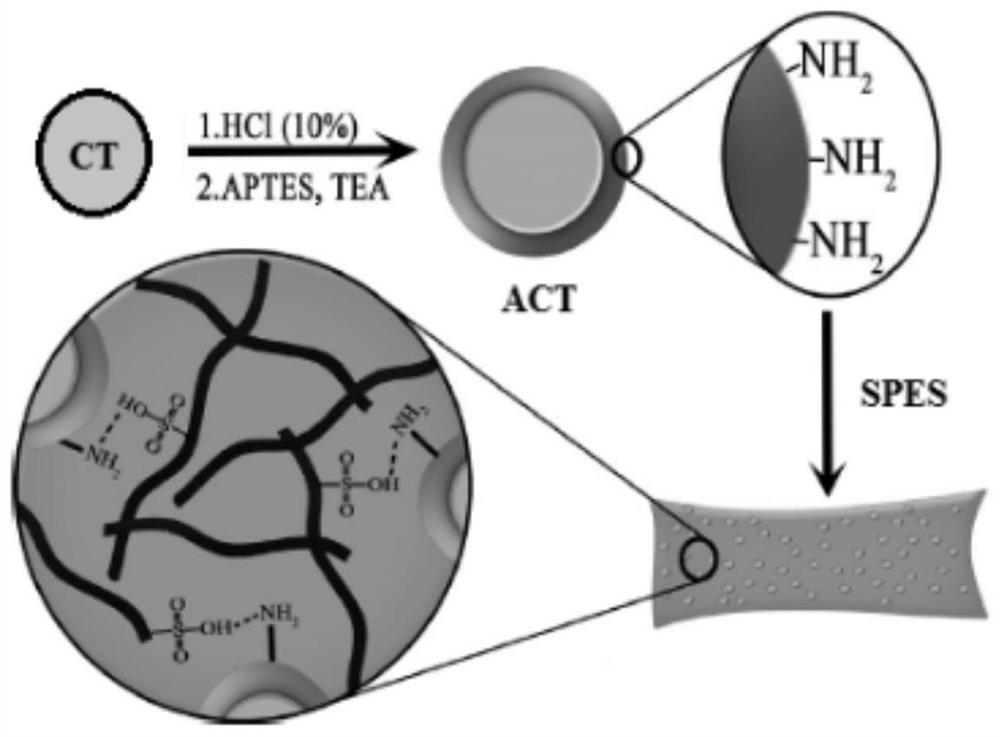

[0038] refer to figure 1 , the mixed solution of SPES and ACT nanoparticles was prepared into a SPES / ACT composite film by solution casting method, in which the SPES film was prepared as a reference, and the prepared films were named Ms and MsACTx respectively, where x represents ACT nanoparticles in nano % by weight in the composite film.

[0039] Stirring at room temperature, 0.995g of SPES was dissolved in 2.5mL of DMAc to obtain a SPES suspension, 0.005g of ACT nanoparticles (0.5wt.%) was ultrasonically dispersed in 2.5ml of DMAc, and then added to the SPES suspension The liquid was stirred at room temperature for 30 minutes to obtain a uniform low-viscosity liquid; the obtained low-viscosity liquid was directly cast on a glass plate at a constant speed with a doctor blade, dried at room temperature for 24 hours, and then dried overnight at 70°C; the prepared Before the membrane is used, it needs to be soaked in 2mol sulfuric acid solu...

Embodiment 2

[0041] MsACT 1 Preparation of:

[0042] refer to figure 1 , the mixed solution of SPES and ACT nanoparticles was prepared into a SPES / ACT composite film by solution casting method, in which the SPES film was prepared as a reference, and the prepared films were named MS and MsACTx, where x represents ACT nanoparticles in nano % by weight in the composite film.

[0043] Stirring at room temperature, 0.99g of SPES was dissolved in 2.5mL of DMAc to obtain a SPES suspension, 0.01g of ACT nanoparticles (1.0wt.%) was ultrasonically dispersed in 2.5ml of DMAc, and then added to the SPES suspension solution, stirred at room temperature for 30 minutes to obtain a uniform low-viscosity liquid; the obtained low-viscosity liquid was directly cast on a glass plate at a constant speed with a doctor blade, dried at room temperature for 24 hours, and then dried overnight at 70°C. Before the membrane is used, it needs to be soaked in 2mol sulfuric acid solution for 24h for pretreatment.

Embodiment 3

[0045] MsACT 2 Preparation of:

[0046] refer to figure 1 , the mixed solution of SPES and ACT nanoparticles was prepared into a SPES / ACT composite film by solution casting method, in which the SPES film was prepared as a reference, and the prepared films were named MS and MsACTx, where x represents ACT nanoparticles in nano % by weight in the composite film.

[0047] Stirring at room temperature, 0.98g of SPES was dissolved in 2.5mL of DMAc to obtain a SPES suspension, 0.02g of ACT nanoparticles (2.0wt.%) was ultrasonically dispersed in 2.5ml of DMAc, and then added to the SPES suspension solution, stirred at room temperature for 30 minutes to obtain a uniform low-viscosity liquid, which was directly cast on a glass plate at a constant speed with a doctor blade, dried at room temperature for 24 hours, and then dried overnight at 70°C. Before the membrane is used, it needs to be soaked in 2mol sulfuric acid solution for 24h for pretreatment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com