Method and device for cleaning contaminated used oil

A technology of equipment and melting bath, which is applied in the field of equipment for purifying polluted waste oil, and can solve problems such as methods for waste oil that have not yet been disclosed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

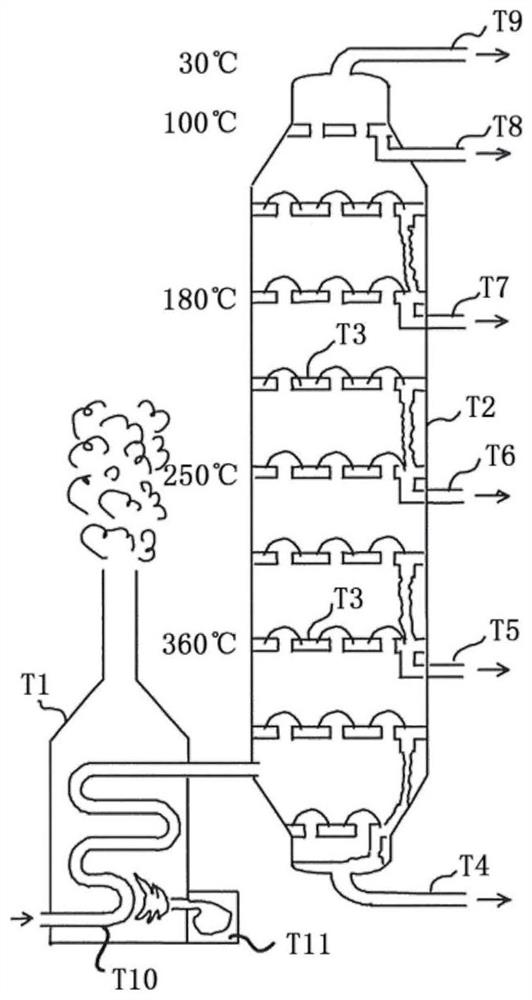

[0058] As shown in Fig. 1, according to the prior art, the crude oil is heated above 360°C in the tube furnace T1, so that the components are largely evaporated. They enter a distillation column T2 built from a plurality of bubble-cap trays T3. Distillates T4 to T9 of the individual fractions are collected in bubble-cap tray T3. It can be seen that the pipe T10 leading the waste oil is in direct contact with the hot gas generated in the combustion chamber T11. In terms of temperature, the hot gas is unevenly distributed in the tube furnace T1 so that the tube T10 is partially overheated. The heat capacity of the hot gas is also low, so that it has to work with higher temperature differences, ie intense heating of the hot gas, which in turn leads to overheating of the tube T10. This cannot avoid the internal slagging of the tube T10, which must be removed during routine maintenance. Such maintenance in turn prohibits the mobile use of such equipment.

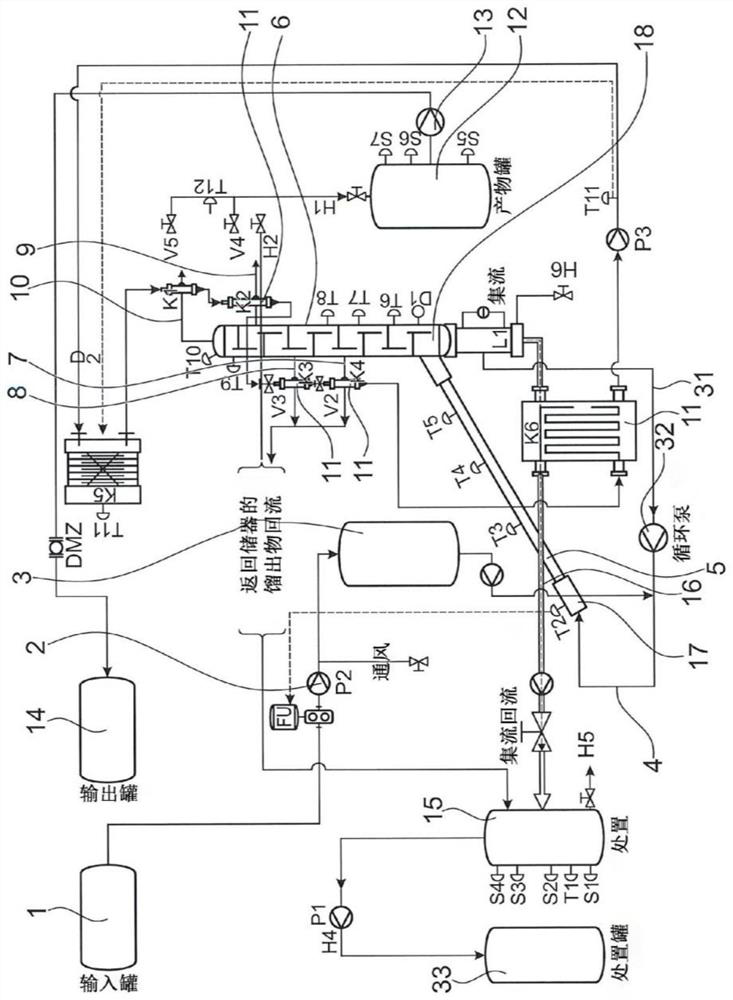

[0059] As shown in Fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com