A centrifugal spray drying device for the production and processing of old hen powder seasoning

A technology of centrifugal spray drying and centrifugal spray, which is applied in household refrigeration equipment, spray evaporation, cooling fluid circulation equipment, etc., can solve the problems of increased energy loss, internal accumulation, incomplete drying of high-temperature heat, etc., to reduce energy consumption and increase The effect of energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

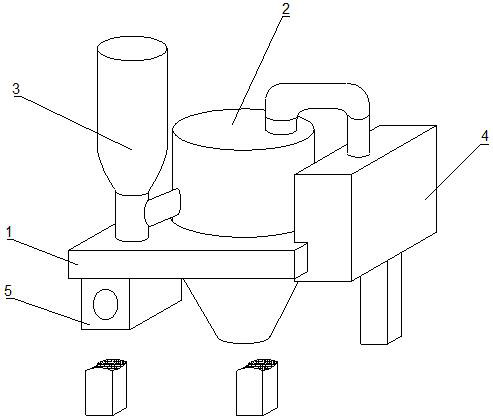

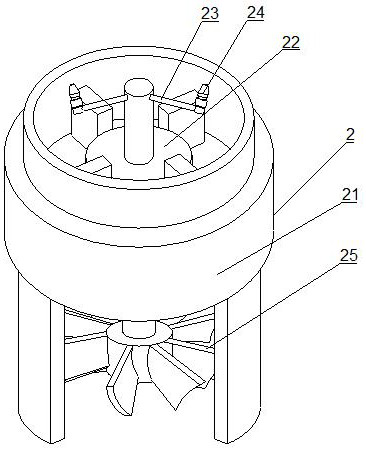

[0032] like Figure 1-9As shown, the present invention provides a centrifugal spray drying device for the production and processing of old hen powder seasoning, comprising a processing table 1, a chicken powder processing tank 2, a chicken powder storage tank 3, a feeding box 4, a motor 5 and a supporting leg, A chicken powder processing tank 2 is fixedly installed on the outer surface of the processing table 1, and the materials are cut, crushed and dried through the chicken powder processing tank 2, and a chicken powder storage tank 3 is fixedly installed on the left outer surface of the processing table 1, Cooperate with the chicken powder storage tank 3 to collect the processed materials for later packaging. The bottom end of the chicken powder storage tank 3 is fixedly connected with a feeding pipe, and one end of the feeding pipe is fixedly connected to the outside of the chicken powder processing tank 2. On the surface, a feeding box 4 is suspended and connected to the ...

Embodiment 2

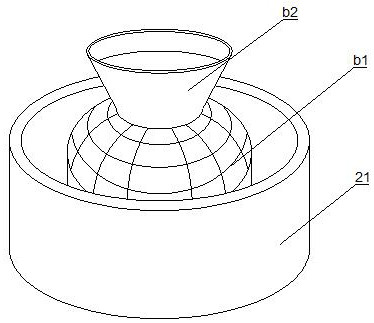

[0035] like Figure 1-9 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the centrifugal spray mechanism includes a centrifugal spray head 24, the centrifugal spray head 24 includes a temperature-proof casing a1, and the inner wall surface of the temperature-proof casing a1 The heat conductor pipe a2 is fixedly connected, the inside of the heat conductor pipe a2 is provided with a jet port, the inside of the heat conductor pipe a2 is provided with an atomizer, the outer surface of the temperature-proof jacket a1 is fixedly connected with a heating shell a3, and the heating shell a3 A heating tube a4 is arranged inside the heating tube a4, and the heating tube a4 presents an independent state inside the heating shell a3. After one of the heating tubes a4 is damaged, the other can continue to work.

[0036] In this embodiment, the heating tube a4 is used for continuous heating inside the heating shell a3, and the heat is tr...

Embodiment 3

[0038] like Figure 1-9 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, a tumbler c31 is fixedly connected to the outer surface of the blade c3, and the tumbler c31 is evenly distributed on the outer surface of the blade c3, and the left side of the blade c3 is A slot c32 is formed on the outer surface of the side, and a squeezing air jet c33 is fixedly connected to the lower surface of the left side of the blade c3.

[0039] In this embodiment, the heating shell a3 is rotated by rotating the disk c1, and the material accumulated in the interior is cut and broken by using the flattened right side of the blade c3 during the rotation process, so as to achieve the purpose of cutting and breaking the materials accumulated in one piece. The effect of cutting is to use the tumbler c31 on the outer surface to collide with the broken material, and then use the slope on the outer surface of the tumbler c31 to roll the material to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com