Stamping die for automobile part production

A technology for stamping dies and auto parts, used in forming tools, manufacturing tools, safety equipment, etc., can solve the problems of lack of mechanical automation and the ability to open and close molds.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

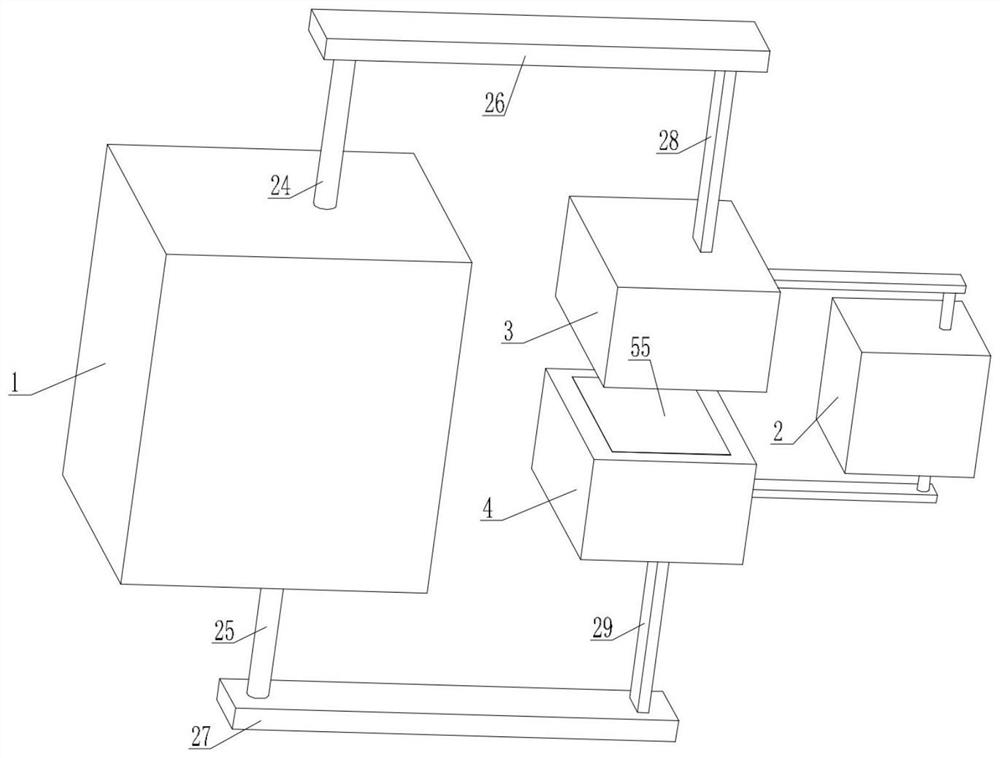

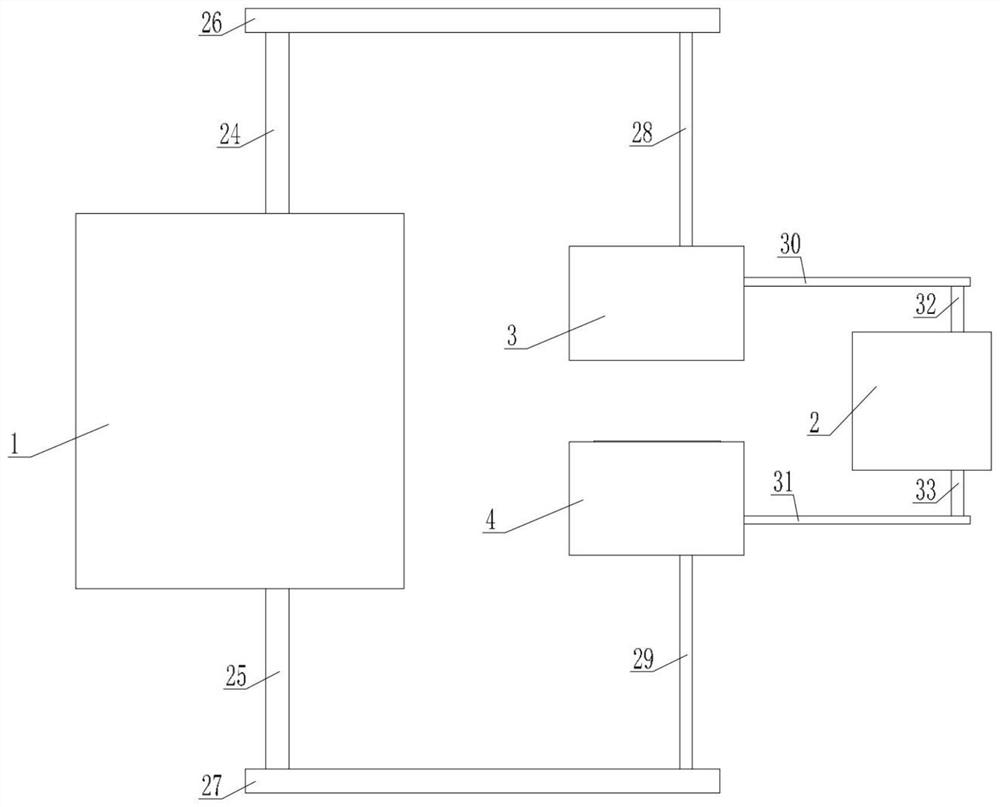

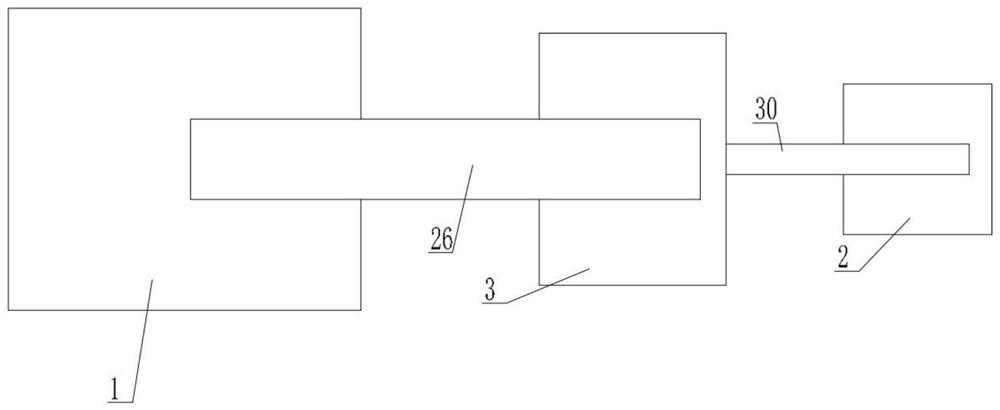

[0029] The present invention is described in detail below in conjunction with accompanying drawing:

[0030] refer to Figure 1 to Figure 9 , a stamping die for the production of automobile parts provided by the present invention includes a power take-off 1, a pressure-sensitive box 2, an upper mold 3, and a lower mold 4, and the inner right side of the power take-off 1 is fixed with a motor bottom plate 5 A motor 6 is fixed on the lower side of the motor bottom plate 5, an output shaft 7 is arranged at the power output end of the lower part of the motor 6, and a cylindrical gear 8 is fixed at the bottom of the output shaft 7, and the cylindrical gear 8 is fixed at the bottom of the output shaft 7. The rear part of the gear 8 is in contact with the front part of the long rack 9, and the left end of the long rack 9 is fixed with a follow-up cross arm 10, and the left end of the follow-up cross arm 10 is connected with the follow-up longitudinal arm 11. The middle part of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com