Electrolytic capacitor working electrolyte leakage-proof device

A technology of electrolytic capacitors and leak-proof devices, which is applied in the field of capacitors and can solve problems such as electrolyte leakage, electrolyte storage, and electrolyte inability to absorb it

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

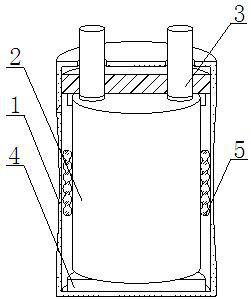

[0037] like Figure 1-6 As shown, the present invention provides a kind of anti-leakage device for working electrolyte of electrolytic capacitor, comprising capacitor body 1, aluminum shell 2 and electrode tube 3, the bottom of electrode tube 3 is plugged with the top of aluminum shell 2, and the top of electrode tube 3 The outer wall runs through the inner wall of the capacitor body 1, the aluminum shell 2 is located inside the capacitor body 1, the outer wall of the aluminum shell 2 is overlapped with an electrolyte adsorption device 5, and the bottom of the aluminum shell 2 is fixedly connected with a heat conduction seat 4, and the heat conduction seat 4 is fixedly installed with a support column 23, and the outer wall of the support column 23 is fixedly installed with a heat conduction plate 24, the inner wall of the heat conduction plate 24 is overlapped with the outer wall of the aluminum shell 2, and the electrolyte adsorption device 5 includes a built-in frame 6 and T...

Embodiment 2

[0040] like Figure 1-6As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the inner wall of the liquid storage device 9 is provided with an arc-shaped slide plate 14 and a sealing device 16, and both ends of the arc-shaped slide plate 14 are connected to the liquid storage The inner wall of the device 9 is slidably connected, the bottom of the sealing device 16 is fixedly connected with the inner wall of the liquid storage device 9, the bottom of the curved slide 14 is overlapped with an air pressure bag 15, and the bottom of the air pressure bag 15 is fixedly connected with the bottom of the inner wall of the liquid storage device 9 , the inner wall of the sealing device 16 is fixedly installed with a gas expansion telescopic assembly 19, the output end of the gas expansion telescopic assembly 19 is fixedly connected with a telescopic plate 20, the top of the telescopic plate 20 is fixedly mounted with a baffle plate 21, an...

Embodiment 3

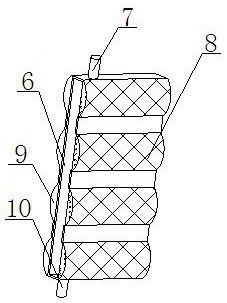

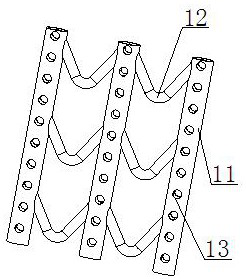

[0044] like Figure 1-6 As shown, on the basis of Example 1, the present invention provides a technical solution: preferably, the inner wall of the built-in frame 6 is provided with a microporous conduit 11 and a transition tube 12, and the transition tube 12 is arranged between the microporous conduits 11, And the two ends of the transition pipe 12 are connected through the outer wall of the microporous conduit 11, the outer wall of the microporous conduit 11 is provided with a through hole 13, the upper and lower ends of the microporous conduit 11 are fixedly connected with the inner wall of the built-in frame 6, and the inner wall of the built-in frame 6 The top is connected with the first connector 7, the bottom of the built-in frame 6 is connected with the second connector 10, the outer walls of the first connector 7 and the second connector 10 are fixedly connected with the outer wall of the heat conduction plate 24, and the second The first connecting piece 7 and the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com