Pickled cucumber sausage and making method thereof

A production method and technology of pickled cucumbers, which are applied in the field of food processing, can solve the problems of no combination of milk cucumbers and meat products, and achieve the effects of outstanding product flavor, reduced salt consumption, and improved uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

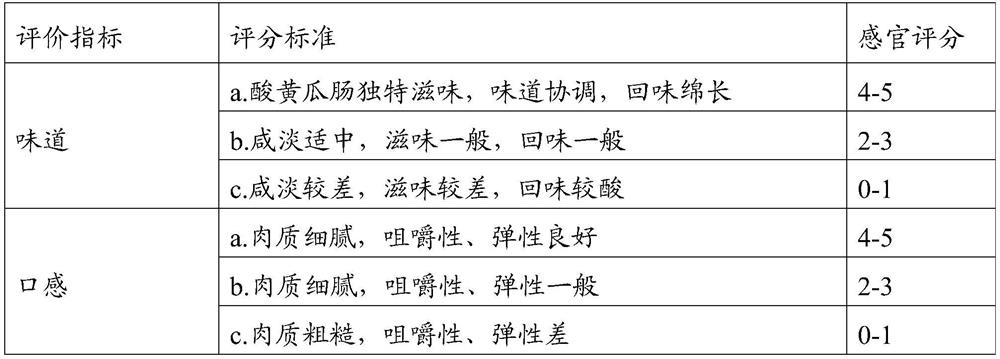

Examples

Embodiment 1

[0045] The pickled cucumber sausage of this example is made from the following raw materials and production methods, and the weight of a single cucumber is 120 grams.

[0046] raw material:

[0047] 57.5 parts of chicken breast meat, 42.5 parts of chicken skin, 7 parts of corn starch, 7 parts of tapioca starch, 6 parts of puffed soybean products, 2 parts of garlic, 30 parts of Russian cucumber, 1.5 parts of mustard seeds, 2.1 parts of edible salt, 2.25 parts of soft white sugar 0.2 parts of compound phosphate, 0.005 parts of sodium nitrite, 0.05 parts of sodium D-isoascorbate, 0.002 parts of monascus red, 0.6 parts of monosodium glutamate, 0.45 parts of carrageenan, 0.3 parts of transglutaminase, 0.2 parts of food flavor, life 16.5 parts of drinking water, 3.5 parts of casings.

[0048] Production Method:

[0049] (1) Material selection and processing: prepare chicken breast meat, chicken skin, cornstarch, tapioca starch, puffed soybean products, garlic, Russian-style milk cuc...

Embodiment 2

[0057] The sour cucumber sausage of this example is made from the following raw materials and production methods, and the weight of a single cucumber is 150 grams.

[0058] raw material:

[0059] 45 parts of chicken breast, 55 parts of chicken skin, 6 parts of cornstarch, 6 parts of tapioca starch, 6 parts of puffed soy products, 3 parts of garlic, 40 parts of Russian cucumber, 3 parts of mustard seeds, 2.6 parts of edible salt, 4 parts of soft white sugar 0.3 parts of compound phosphate, 0.005 parts of sodium nitrite, 0.1 part of sodium D-isoascorbate, 0.004 parts of monascus red, 0.8 parts of monosodium glutamate, 0.6 parts of carrageenan, 0.4 parts of transglutaminase, 0.3 parts of food flavor, life 16 parts of drinking water, 4 parts of casings.

[0060] Production Method:

[0061] (1) Material selection and processing: prepare chicken breast meat, chicken skin, cornstarch, tapioca starch, puffed soybean products, garlic, Russian-style milk cucumber, mustard seeds, edibl...

Embodiment 3

[0069] The pickled cucumber sausage of this example is made from the following raw materials and production methods, and the weight of a single cucumber is 90 grams.

[0070] raw material:

[0071] 70 parts of chicken breast, 30 parts of chicken skin, 4 parts of cornstarch, 4 parts of tapioca starch, 4 parts of soybean protein, 1 part of garlic, 20 parts of Russian-style cucumber, 1 part of mustard seed, 1.8 parts of edible salt, 0.5 parts of soft white sugar 0.1 part of compound phosphate, 0.005 part of sodium nitrite, 0.1 part of sodium D-isoascorbate, 0.004 part of monascus red, 0.8 part of monosodium glutamate, 0.3 part of carrageenan, 0.2 part of transglutaminase, 0.1 part of food flavor, life 15 parts of drinking water, 3 parts of casings.

[0072] Production Method:

[0073] (1) Material selection and processing: prepare chicken breast meat, chicken skin, cornstarch, tapioca starch, puffed soybean products, garlic, Russian-style milk cucumber, mustard seeds, edible sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com