Waste gas treatment device

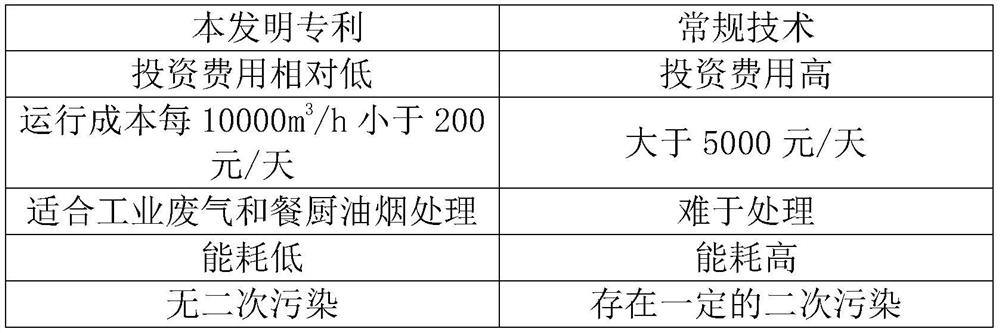

A technology for treating device and waste gas, which is applied in the directions of air quality improvement, filtration of dispersed particles, separation of dispersed particles, etc., can solve the problems of low investment cost and operating cost, difficult treatment of kitchen waste gas, etc., and achieve the effect of low investment and operating cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

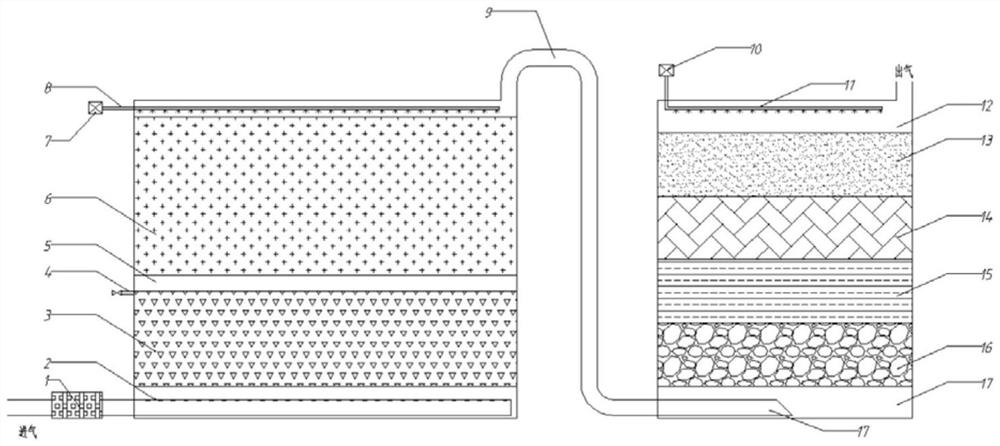

[0065] Such as figure 1 As shown, Embodiment 1 of the present invention provides a waste gas treatment device, including: a filtration system, a biological treatment unit, and a bioaugmentation and nutrient atomization reaction zone;

[0066] The filter system 1 is arranged on the outside of the bottom of the processing device, and is used to remove particulate pollutants (PM10) in the exhaust gas; avoid blocking the back-end system, and ensure the operation effect of the back-end system;

[0067] The biological treatment unit is built in the treatment device, and the bottom of the biological treatment unit is connected to the filter system, which is used to guide the waste gas in the filter system to pass through the lower biofilm reaction zone in the bacterial liquid in the biological treatment unit from bottom to top After the upper biofilm reaction zone located above the liquid surface layer of the bacterial solution and the microbial strains located on the top of the trea...

specific Embodiment

[0115] 1. Analyze the source of waste gas and confirm that it is industrial waste gas and / or cooking fume waste gas, and the industrial waste gas is determined to be the stench produced by hazardous waste warehouses, sewage treatment workshops, sludge drying workshops, production workshops, fermentation workshops or waste gas incinerators Gas or malodorous gas produced by landfill plants or industrial malodorous waste gas produced by other links;

[0116] 2. After determining the source of waste gas, further confirm the treatment volume of waste gas, main characteristic pollutants and concentrations, currently implemented emission standards, odor value and other indicators;

[0117] 3. Design the treatment device according to the gas volume, main characteristic pollutants and emission standards;

[0118]Fourth, according to the composition of waste pollutants, determine the optimal strain ratio, the type of filler for each unit, etc.;

[0119] 5. Deal with project implementat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com