Multi-layer co-extrusion full-degradation high-barrier packaging film and preparation method thereof

A multi-layer co-extrusion and packaging film technology, which is applied to chemical instruments and methods, layered products, and other household appliances, can solve the problems of low cost, short service life, and attenuation of product barrier properties, achieving good weather resistance, Prevents white pollution and slows the decay of barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

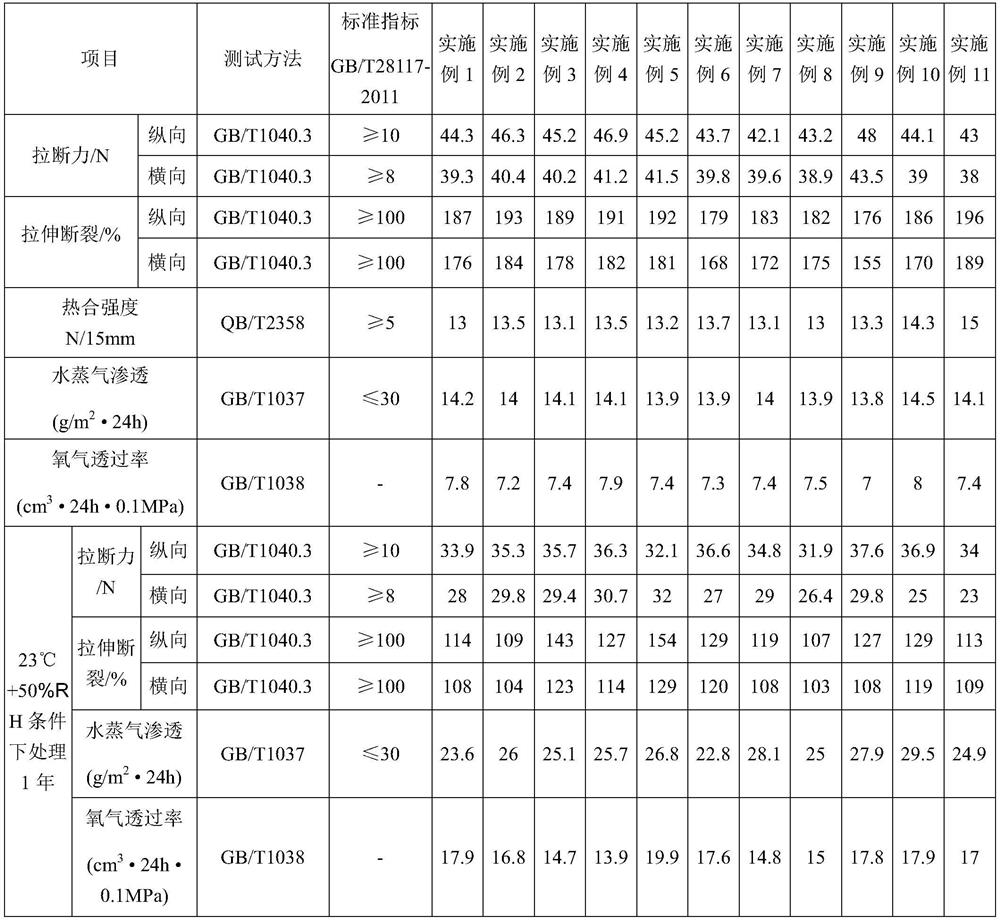

[0029] The present invention will be further described below through specific examples.

[0030] The main production equipment used to make the multi-layer co-extrusion fully degradable high-barrier packaging film in the present invention is a five-layer co-extrusion blow molding unit. Other devices, unless otherwise specified, adopt conventional production equipment in this field.

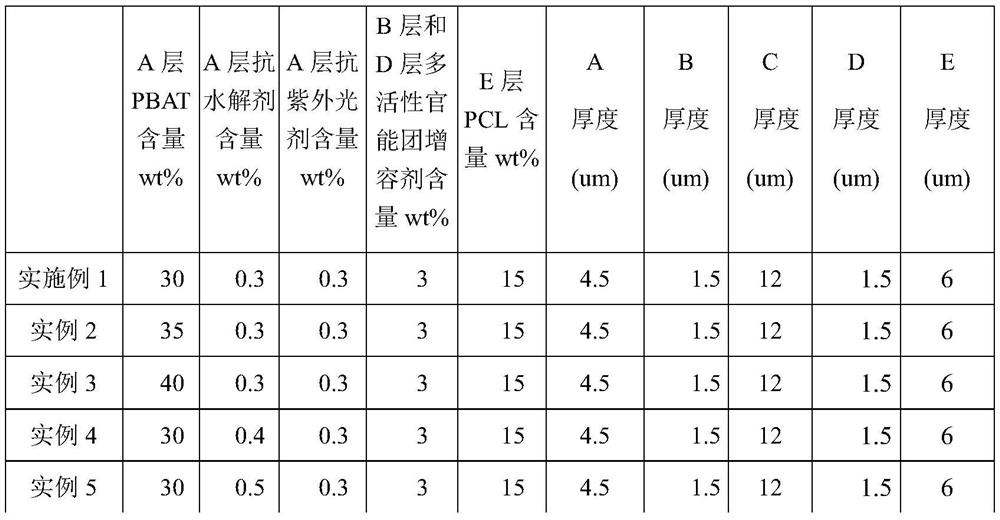

[0031] The raw materials used in the embodiments of the present invention are shown in Table 1 below, but are not limited thereto:

[0032] Table 1 The main raw material manufacturers of the embodiment of the present invention

[0033]

[0034] Additive name manufacturers Grade Carbodiimide antihydrolysis agent Shanghai Laian Industrial Co., Ltd. STABAXOL I Anti-ultraviolet agent Trump Chemical Co., Ltd. UV-531 Multi-reactive functional group compatibilizer BASF ADR-4400

[0035] The multi-layer co-extrusion fully degradable high-barrier packaging f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com