Nickel oxide nanoparticles and synthesis method thereof

A nanoparticle and synthesis method technology, applied in the field of chemical engineering, can solve the problems of cumbersome operation, high viscosity, long stirring time, etc., and achieve the effects of less interference from external factors, short operation time, and water saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] (1) Weigh 150g of sodium alginate powder, add it to the pot of the wet shear granulator, close the device, set the stirring rate and shear rate to 350rpm and 1500rpm respectively, start the stirring paddle and the cutter, and pass through the peristaltic The pump sprays 150mL of binder (deionized water) into the pot from the spray gun, and performs shear granulation treatment (time is 540s); after the binder is sprayed, stop the experiment and unload to obtain sodium alginate wet particles;

[0051] (2) Put the sodium alginate wet granules described in step (1) into an oven, and bake at 60° C. for 24 hours to obtain sodium alginate granules;

[0052] (3) Add 10 g of dried sodium alginate particles (1 mm in particle size) to 200 mL of nickel nitrate hexahydrate aqueous solution (0.05 mol / L) and react for 1 hour to obtain nickel alginate particles; After washing with deionized water, carry out vacuum drying at 90°C for 24 hours;

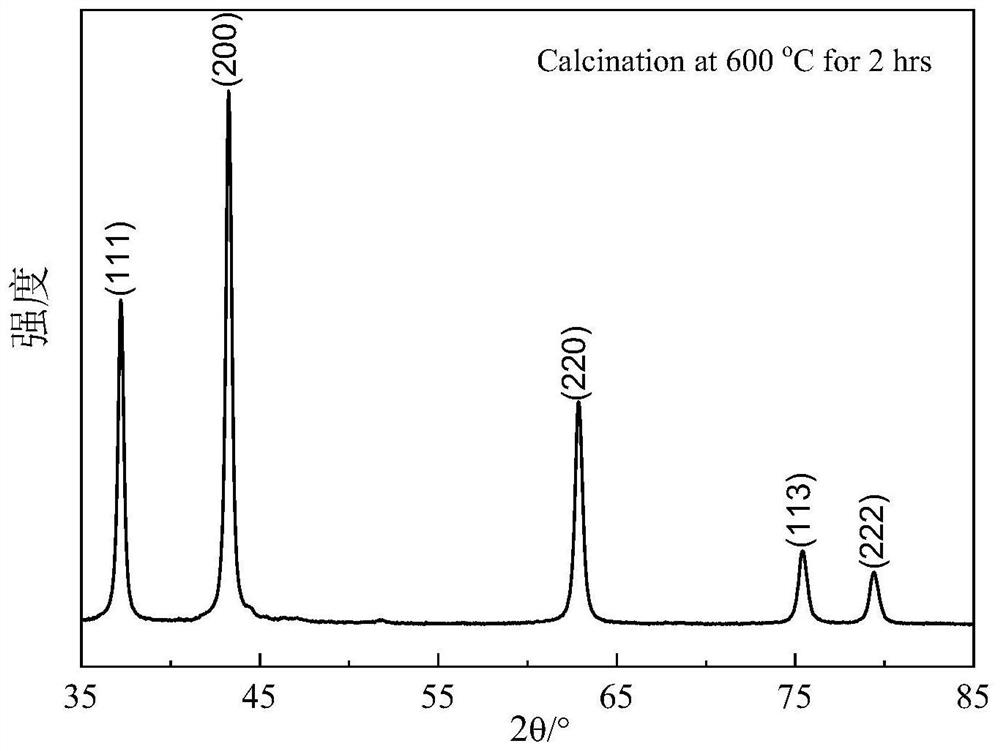

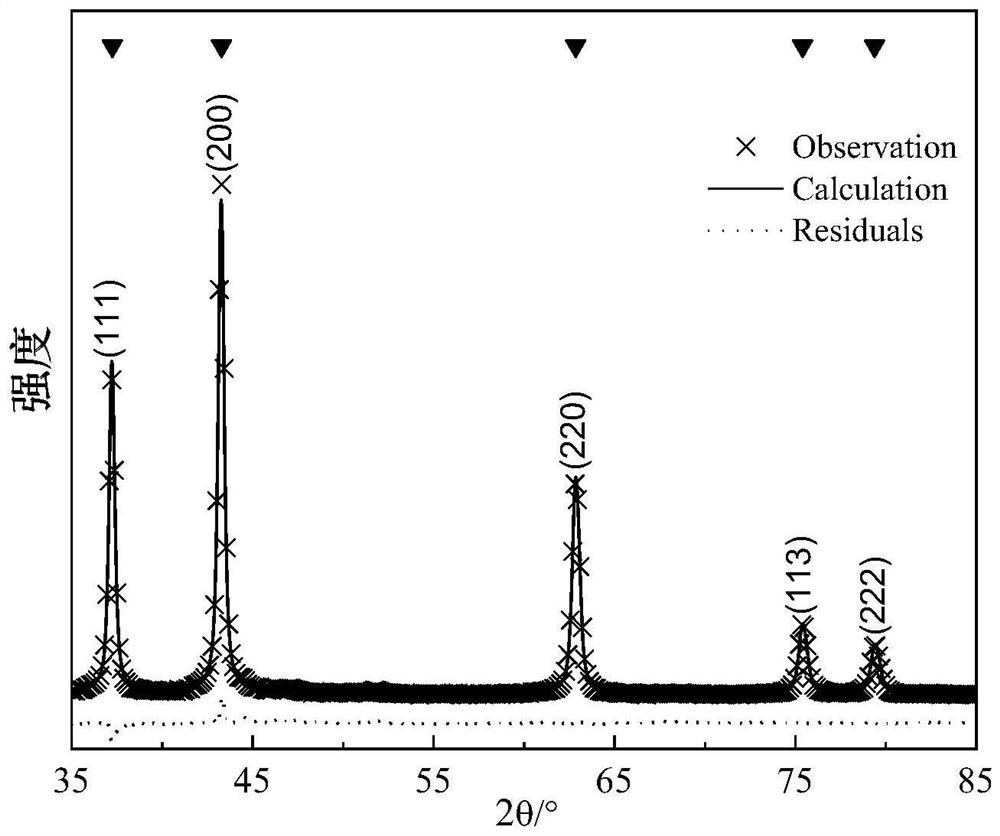

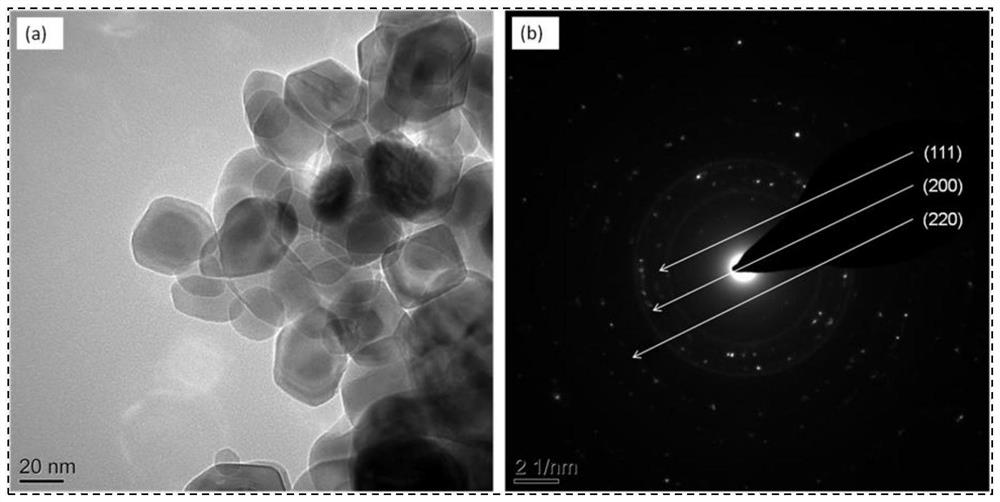

[0053] (4) The vacuum-dried nickel algi...

Embodiment 2

[0066] (1) Weigh 150g of sodium alginate powder, add it to the pot of the wet shear granulator, close the device, set the stirring rate and shear rate to 350r and 1500r respectively, start the stirring paddle and the cutter, and pass through the peristaltic The pump sprays 150mL of binder (deionized water) into the pot from the spray gun, and performs shear granulation treatment (time is 540s); after the binder is sprayed, stop the experiment and unload to obtain sodium alginate wet particles;

[0067] (2) Put the sodium alginate wet granules described in step (1) into an oven, and bake at 60° C. for 24 hours to obtain sodium alginate granules;

[0068] (3) Add 10 g of dried sodium alginate particles (with a particle size of 1 mm) into 200 mL of nickel nitrate hexahydrate aqueous solution (0.05 mol / L) and react for 1 h to obtain nickel alginate particles. After the obtained nickel alginate particles were washed with deionized water, they were vacuum-dried at 90°C for 24 hours...

Embodiment 3

[0072] (1) Weigh 150g of sodium alginate powder, add it to the pot of the wet shear granulator, close the device, set the stirring rate and shear rate to 350r and 1500r respectively, start the stirring paddle and the cutter, and pass through the peristaltic The pump sprays 150mL of binder (deionized water) into the pot from the spray gun, and performs shear granulation treatment (time is 540s); after the binder is sprayed, stop the experiment and unload to obtain sodium alginate wet particles;

[0073] (2) Put the sodium alginate wet granules described in step (1) into an oven, and bake at 60° C. for 24 hours to obtain sodium alginate granules;

[0074] (3) Add 10 g of dried sodium alginate particles (with a particle size of 1 mm) into 200 mL of nickel nitrate hexahydrate aqueous solution (0.05 mol / L) and react for 1 h to obtain nickel alginate particles. After the obtained nickel alginate particles were washed with deionized water, they were vacuum-dried at 90°C for 24 hours...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com