Garment spinning cloth processing equipment

A technology for processing equipment and fabrics, which is applied in the field of fabric processing equipment for clothing and textiles, can solve problems such as inconvenient adjustment of dyeing methods, and achieve the effects of accelerating drying speed, ensuring orderly progress, and avoiding too close distances.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

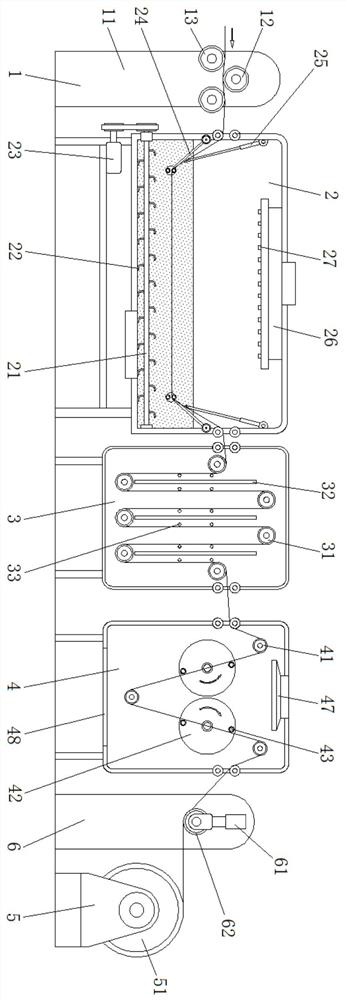

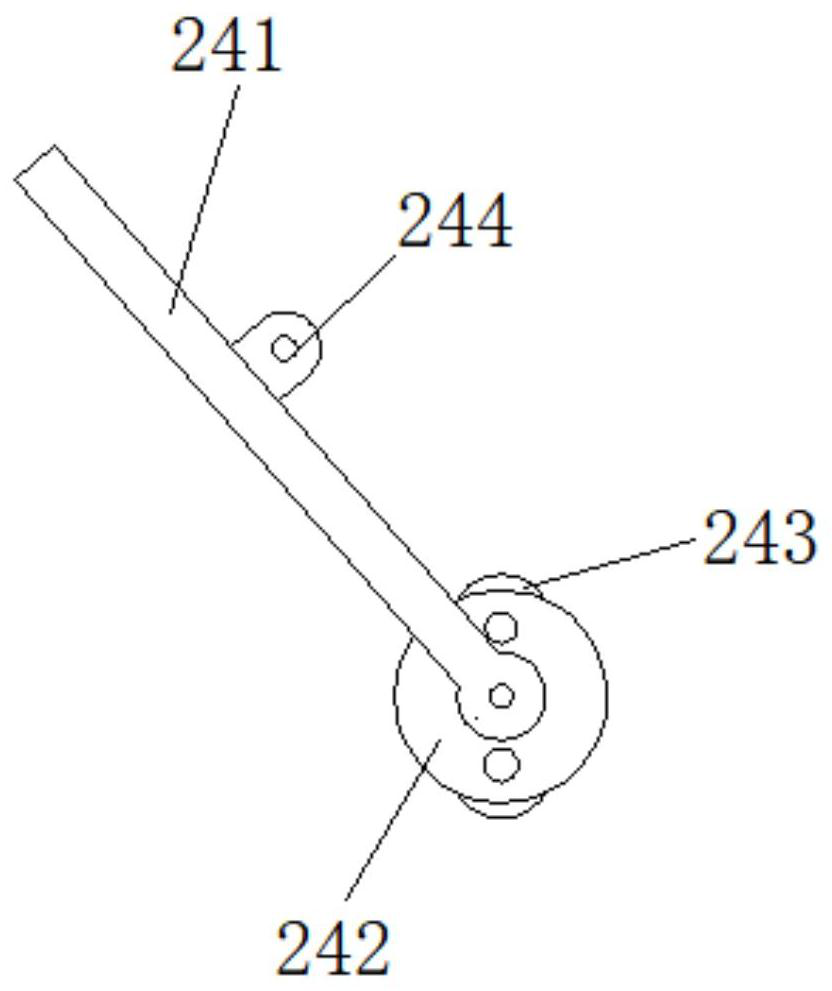

[0038] refer to Figure 1-4 , a kind of fabric processing equipment for garment textile provided by the present invention, comprises dyeing box 2, feed inlet, discharge port, some jet dyeing heads 27, connecting rod 241, guide roller 243 and cylinder 25, dyeing box 2, for To hold the dye, the dyeing box 2 is provided with an inlet and an outlet, the cloth enters the dyeing box 2 from the inlet, and leaves the dyeing box 2 from the outlet; several spray dyeing The head 27 is located inside the dyeing box 2, the spraying head 27 communicates with the dye in the dyeing box 2, and the spraying head 27 is used to spray dye to the cloth; the connecting rod 241 is connected to the inner wall of the dyeing box 2 Rotation connection; guide roller 243 is connected with described connecting rod 241, and cloth walks around described guide roller 243; The cylinder barrel of described air cylinder 25 is hinged with described dyeing box 2 inner wall, and the telescopic link of described air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com