Method for controlling vibration based on bifurcation and chaotic analysis

A chaotic and dynamic technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of large nonlinear vibration of thin-walled parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

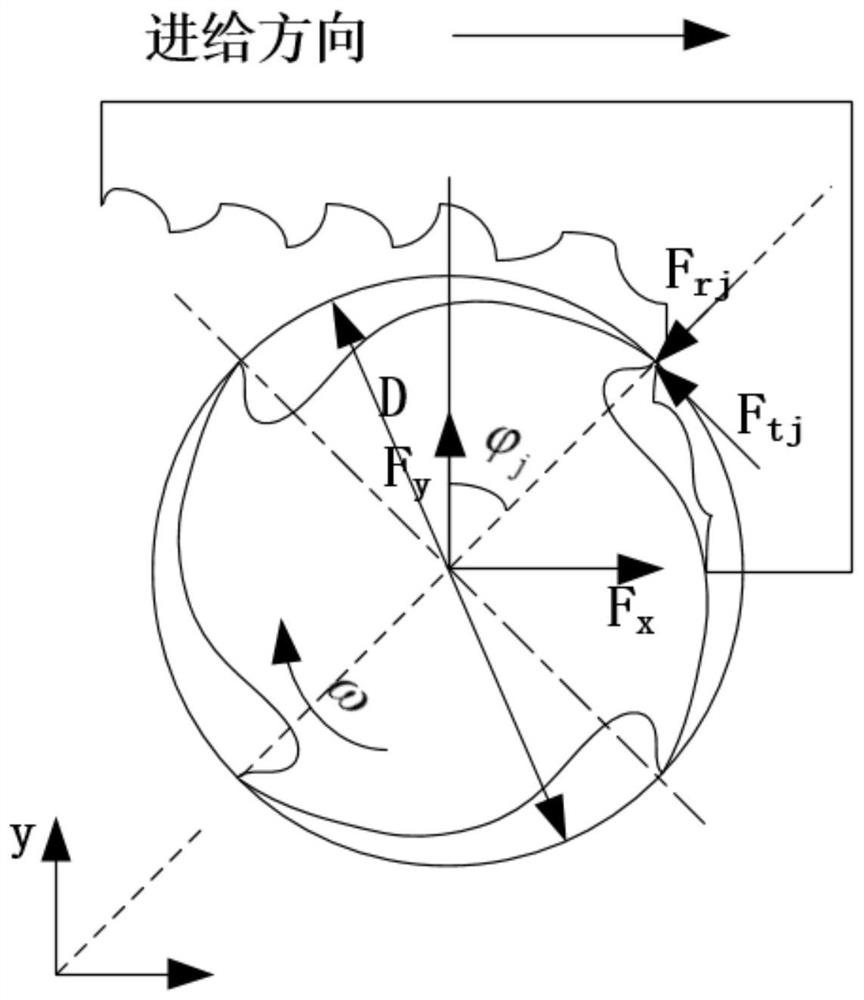

[0075] The first part establishes the dynamic milling force model, the steps are as follows:

[0076] 1) Establish a physical model of milling dynamics, which consists of two degrees of freedom elastic damping systems perpendicular to each other:

[0077]

[0078]

[0079] In the formula, a p ——Milling depth; Δx, Δy——Regenerate flutter, calculated from the difference between the vibration displacement of the current tooth and the previous milling tooth, T——The rotation period of each tooth, T=2π / (Nω), N——The number of teeth of the milling cutter ;ω——spindle angular velocity; a ij (t)——Time-varying milling force coefficient, i,j=1,2, when the milling cutter tooth is between the cutting angle and the cutting angle, a ij (t) can be expressed as the average value of the tooth position angle.

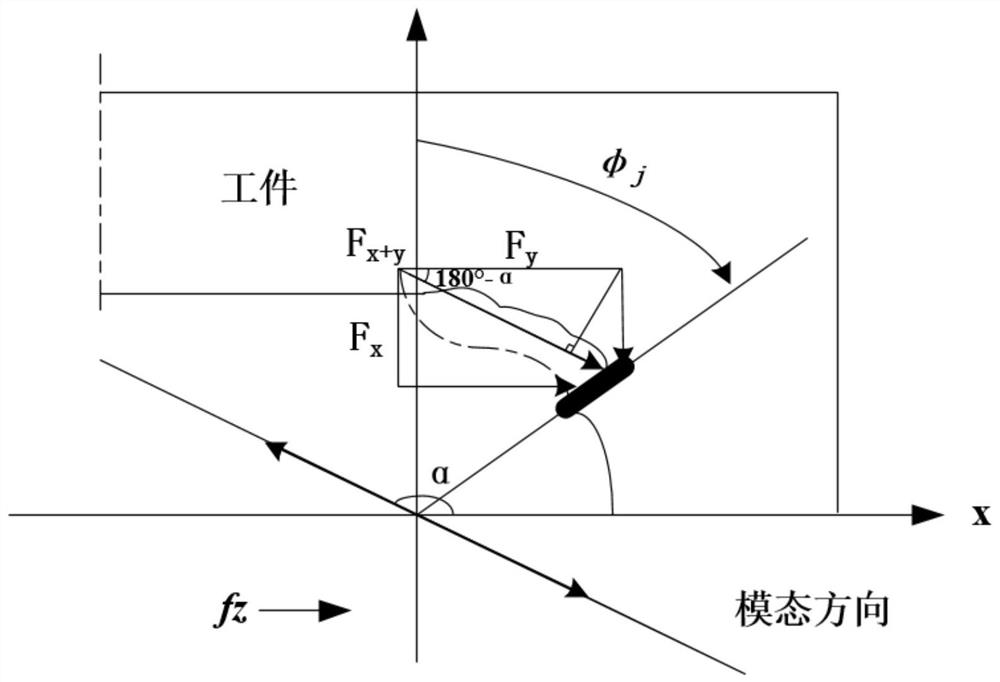

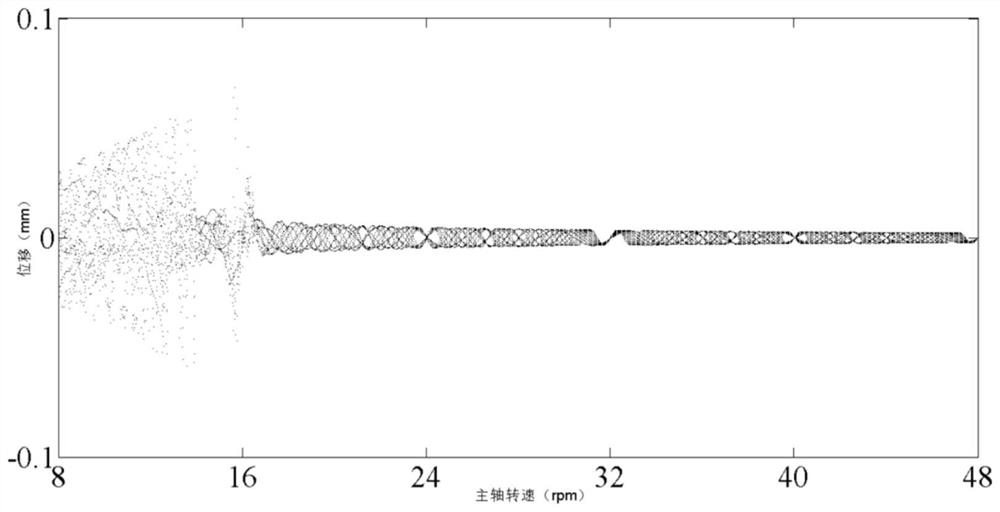

[0080] For simplicity, as in figure 2 As shown, suppose the milling system is a single-degree-of-freedom system, w(t) is the dynamic displacement of the system in the modal directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com