A kind of modified bamboo fiber reinforced aerated concrete and preparation method thereof

A technology of air-entrained concrete and bamboo fiber, applied in ceramic products, other household appliances, climate sustainability, etc., to achieve the effects of good compatibility, reduced hygroscopicity, and improved interfacial bonding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The preparation of modified bamboo fiber reinforced aerated concrete, the concrete steps are:

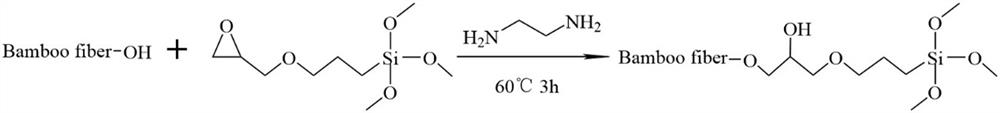

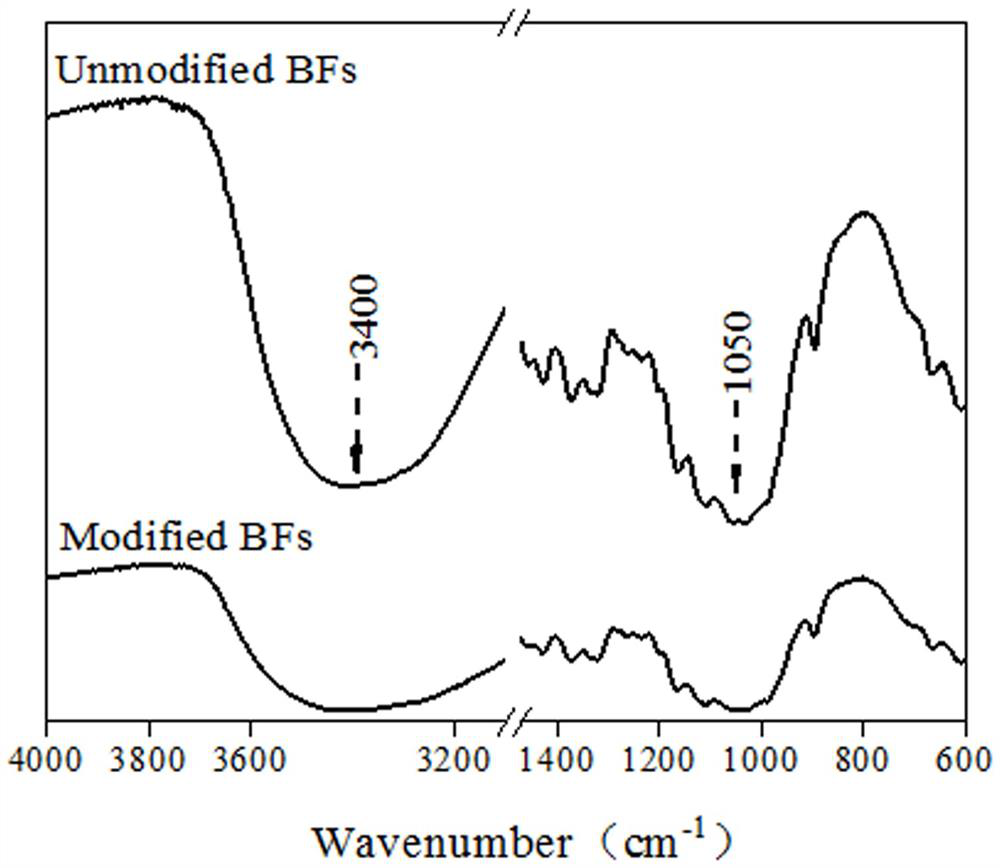

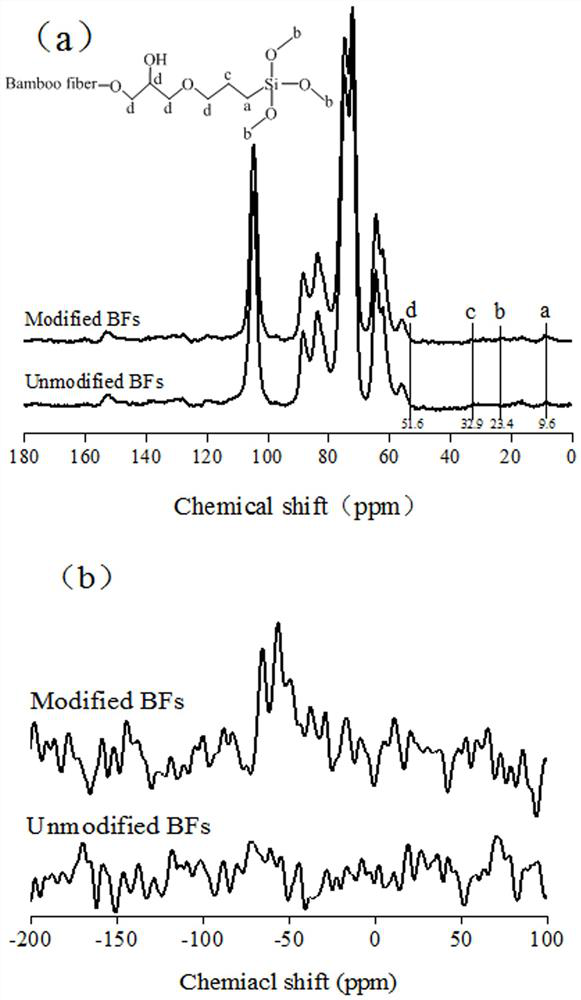

[0026] 1) Bamboo fiber modification process: Weigh 3.2g of bamboo fiber and dry it in an oven at 103°C to a constant weight for later use; prepare a KH560 ethanol solution with a concentration of 1 wt% as a modifier, and the amount of KH560 is 10% of the quality of the bamboo fiber. ; Take ethylenediamine as the catalyst, and its dosage is 10% of KH560. Take an appropriate amount of bamboo fibrils, stir the modifier solution and bamboo fibrils in a constant-temperature heating magnetic stirrer at 60°C for 3 hours to ensure that the fibers are in full contact with the modifier, wash the modified fibers with water and put them in an oven for drying (103 ℃, 24h), sealed in a vacuum bag and stored for later use.

[0027]2) Preparation of modified bamboo fiber aerated concrete test block: According to the national standard of the People's Republic of China GB 11969-2008 "Test met...

Embodiment 2

[0029] The preparation of modified bamboo fiber reinforced aerated concrete composite material, the specific steps are:

[0030] 1) Modification process of bamboo fiber: Weigh 9.6g of bamboo fiber and dry it in an oven at 103°C to a constant weight for later use; prepare a 1wt% concentration of KH560 ethanol solution as a modifier, and the amount of KH560 is 10% of the mass of bamboo fiber. ; Take ethylenediamine as the catalyst, and its dosage is 10% of KH560. Take an appropriate amount of bamboo fibrils, stir the modifier solution and bamboo fibrils in a constant-temperature heating magnetic stirrer at 60°C for 3 hours to ensure that the fibers are in full contact with the modifier, wash the modified fibers with water and put them in an oven for drying (103 ℃, 24h), sealed in a vacuum bag and stored for later use.

[0031] 2) Preparation of modified bamboo fiber aerated concrete test block: According to the national standard of the People's Republic of China GB 11969-2008 "...

Embodiment 3

[0033] The preparation of modified bamboo fiber reinforced aerated concrete, the concrete steps are:

[0034] 1) Bamboo fiber modification process: Weigh 16g of bamboo fiber and dry it to constant weight in an oven at 103°C for later use; prepare a KH560 ethanol solution with a concentration of 1wt% as a modifier, and the amount of KH560 is 10% of the quality of the bamboo fiber; Using ethylenediamine as catalyst, its dosage is 10% of KH560. Take an appropriate amount of bamboo fibrils, stir the modifier solution and bamboo fibrils in a constant-temperature heating magnetic stirrer at 60°C for 3 hours to ensure that the fibers are in full contact with the modifier, wash the modified fibers with water and put them in an oven for drying (103 ℃, 24h), sealed in a vacuum bag and stored for later use.

[0035] 2) Preparation of modified bamboo fiber aerated concrete test block: According to the national standard of the People's Republic of China GB 11969-2008 "Test method for the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com