Hollow carbon-coated copper oxide nanoparticle catalyst as well as preparation method and application thereof

A technology of copper oxide and nanoparticles, applied in electrolysis components, electrodes, electrolysis process, etc., can solve the problem of low conversion rate of ammonia and achieve the effect of high production rate, cheap and easy-to-obtain raw materials, and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

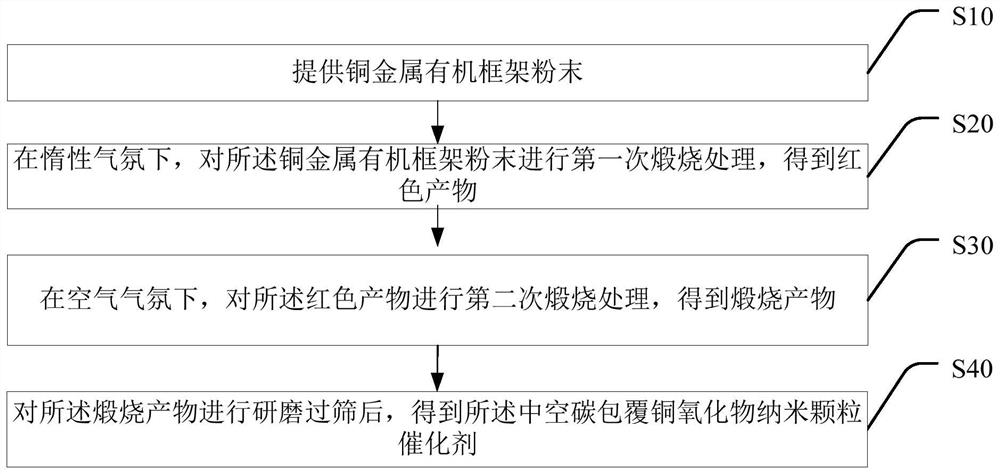

Method used

Image

Examples

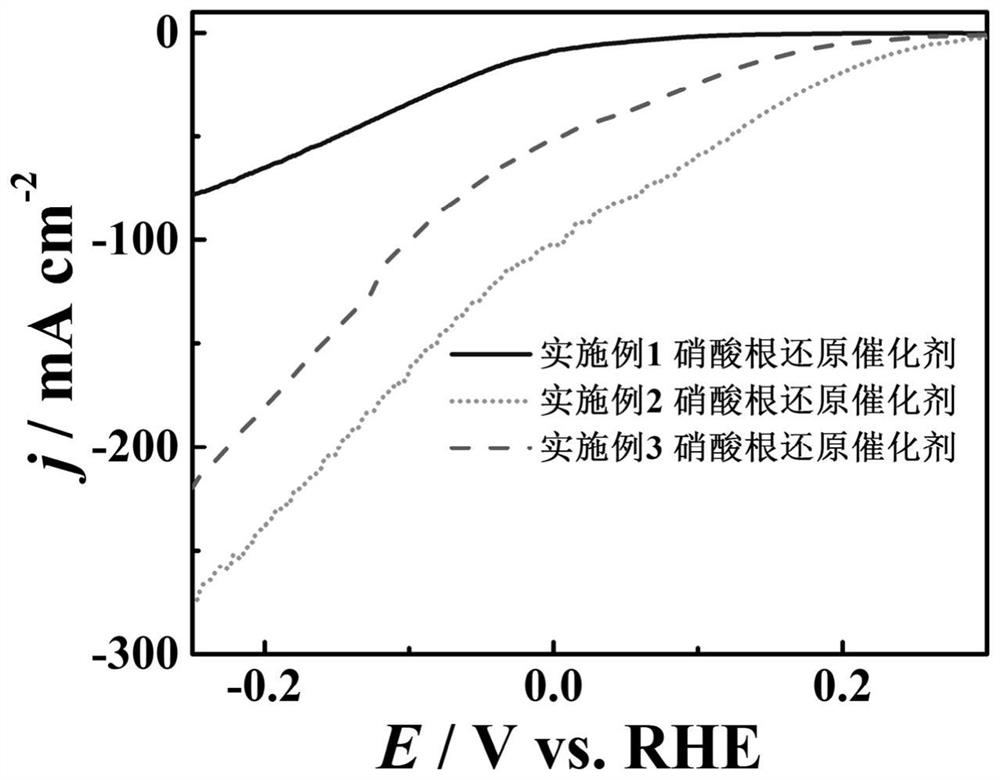

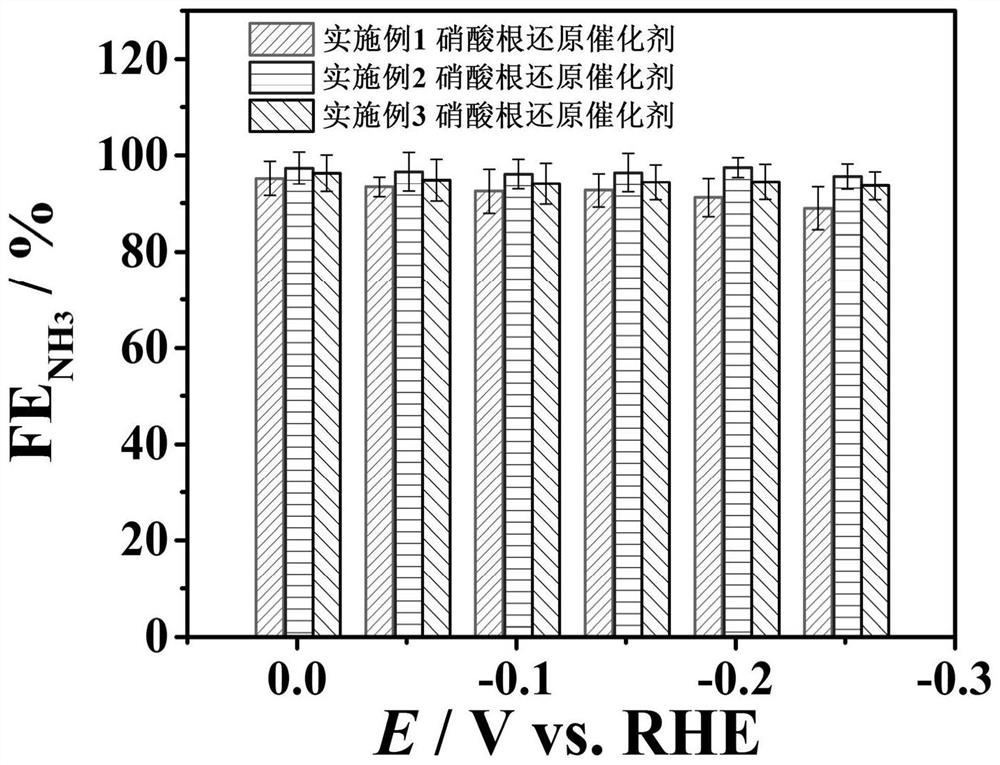

Embodiment 1

[0050] Weigh 1g of the Cu-MOF synthesized above, evenly distribute it in the magnetic boat, and then react in a tube furnace at 400°C for 2 hours under the protection of argon, cool to room temperature, and sieve;

[0051] Preparation of nitrate electrochemical reduction catalysts with carbon-coated copper nanoparticles.

Embodiment 2

[0053] Weigh 100 mg of the carbon-coated copper nanoparticles obtained in Example 1, evenly distribute them in a magnetic boat, and then react in a muffle furnace at 300° C. for 30 minutes under air, cool to room temperature, and sieve;

[0054] A catalyst for the electrochemical reduction of nitrate by hollow carbon-coated copper oxide nanoparticles with abundant oxygen vacancies was prepared.

Embodiment 3

[0056] Weigh 100 mg of carbon-coated copper nanoparticles obtained in Example 1, distribute them evenly in a magnetic boat, and then react in a muffle furnace at 300° C. for 60 minutes under air, cool to room temperature, and sieve;

[0057] A nitrate electrochemical reduction catalyst was prepared with hollow carbon-coated copper oxide nanoparticles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com