Front-end wet-type purification combined equipment

A technology of wet purification and combined equipment, which is applied in the fields of non-methane total hydrocarbon purification devices, particulate matter, catering oil fumes, and industrial dust removal. Maintenance cost, effect of ensuring public safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

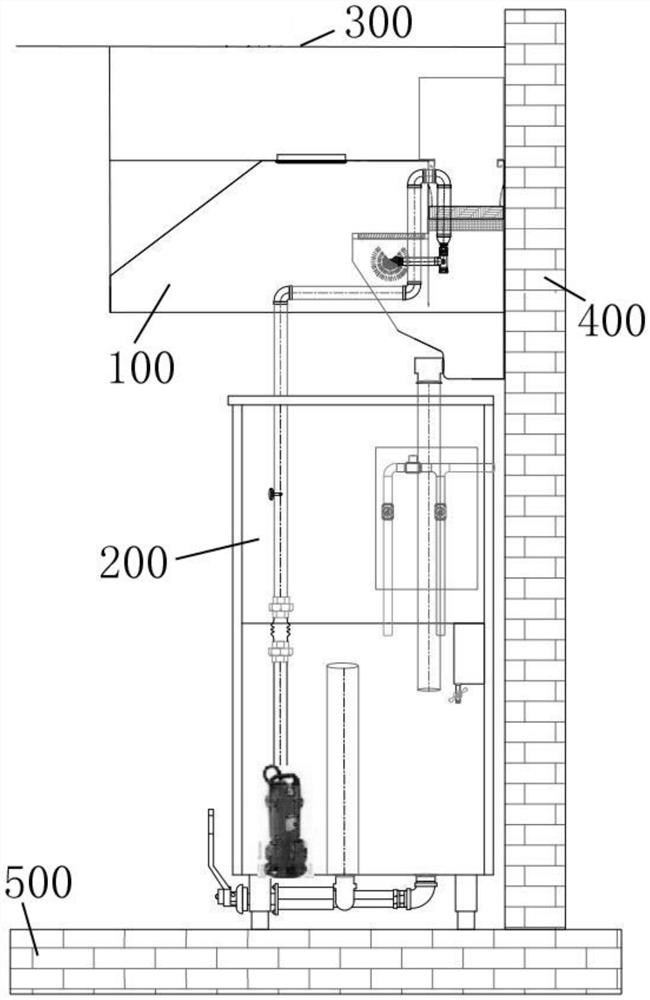

[0030] Such as figure 1 As shown, the front-end wet purification combined equipment includes a wet exhaust gas purification device 100 above and a purification intelligent control box 200 below. The top of the wet exhaust gas purification device 100 is fixed on the ceiling surface 300, and the purification intelligent control box 200 is placed on the ground 500 , and the front-end wet purification combination equipment can be arranged near the wall 400 between the ceiling surface 300 and the ground 500 .

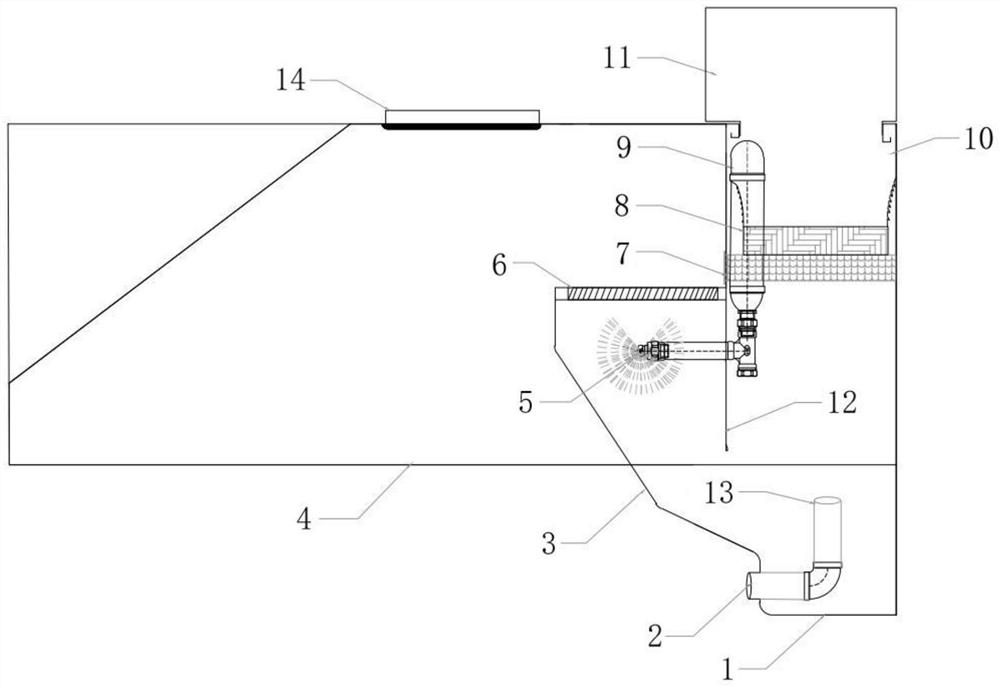

[0031] Such as Figure 2 to Figure 3 As shown, the wet exhaust gas purification device 100 includes a wet purification equipment reaction box 3 and a stove body 4, the wet purification equipment reaction box 3 is located at the front end of the smoke stove body 4, and the wet purification equipment reaction box 3 is from top to bottom The air storage box 10, the spray purification device 5 and the water return tank 1 are arranged in sequence at the bottom. The spray purific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com