Wet-type waste gas purification intelligent control box

A technology of intelligent control and exhaust gas purification, which is applied in the fields of catering oil fume, particulate matter, industrial dust removal, and non-methane total hydrocarbon purification devices. Maintenance cost, the effect of low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

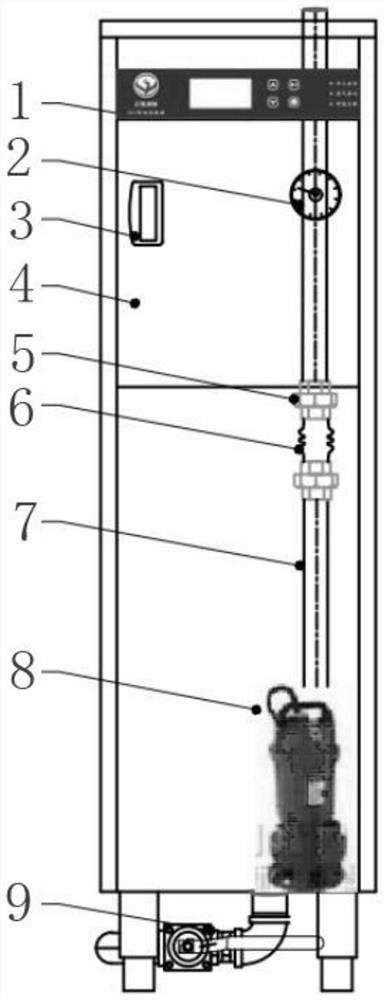

[0025] Such as figure 1 As shown, the wet exhaust gas purification intelligent control box includes an upper control box and a lower water outlet box 12, the front panel of the control box is provided with an intelligent display panel 1 for displaying the wet exhaust gas purification intelligent control bin data. The bottom four corners of the wet exhaust gas purification intelligent control box are provided with gravity feet 23 for support.

[0026] The front end of the control box is provided with a front door 4 , and the front door 4 is provided with a door handle 3 for opening the front door 4 . A water inlet pipe is arranged in the control box, and a water pressure gauge 2 is arranged on the water inlet pipe. Shock rubber sleeve 6, the two ends of the shock-absorbing rubber sleeve 6 are provided with galvanized union 5. The lower end of the circulating upper water pipe 7 is connected with a circulating water pump 8 .

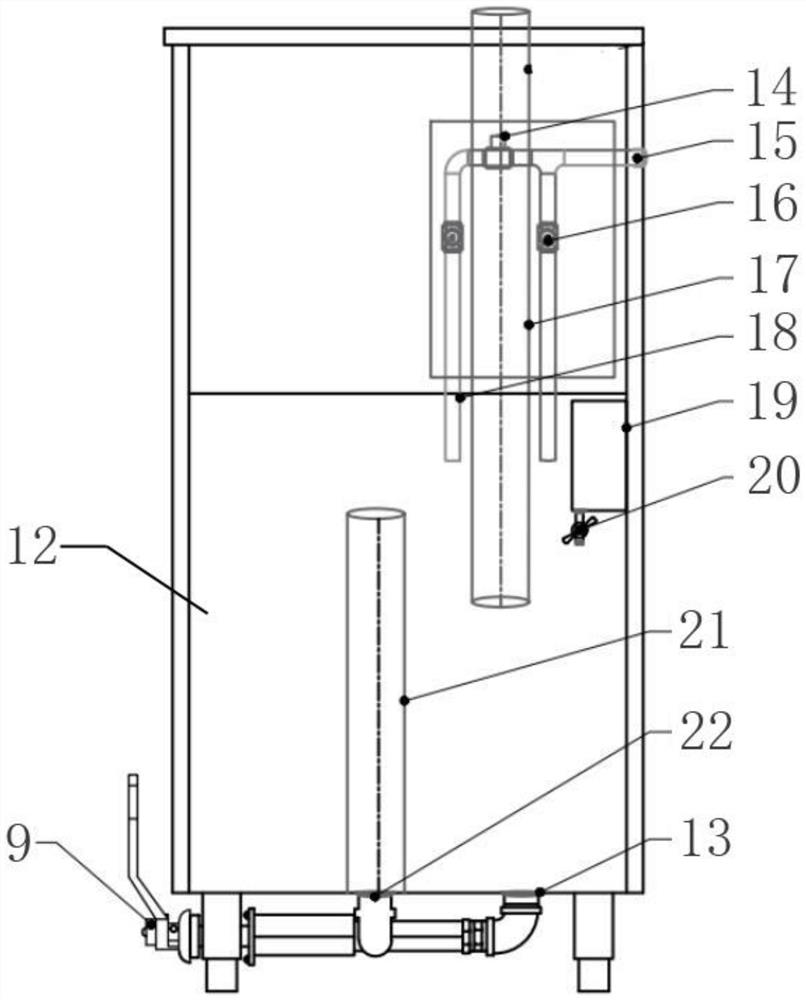

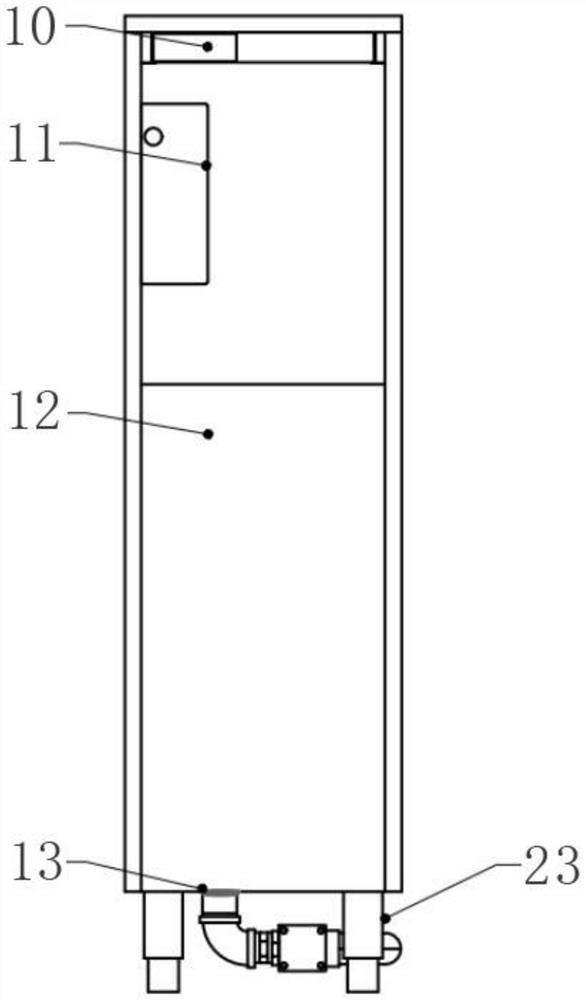

[0027] Such as figure 2 and image 3 As shown,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com