Method for recycling industrial low-temperature heat energy and externally-hung heat pump system

A heat pump system, plug-in technology, applied in the direction of heat pumps, lighting and heating equipment, refrigeration components, etc., can solve the problems of energy-saving and emission-reduction upgrading and transformation of unsuitable process equipment, low-temperature heat energy is not recycled, and engineering implementation is difficult, etc., to achieve Reduce corrosion resistance requirements and safety risks, reduce consumption, and have strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

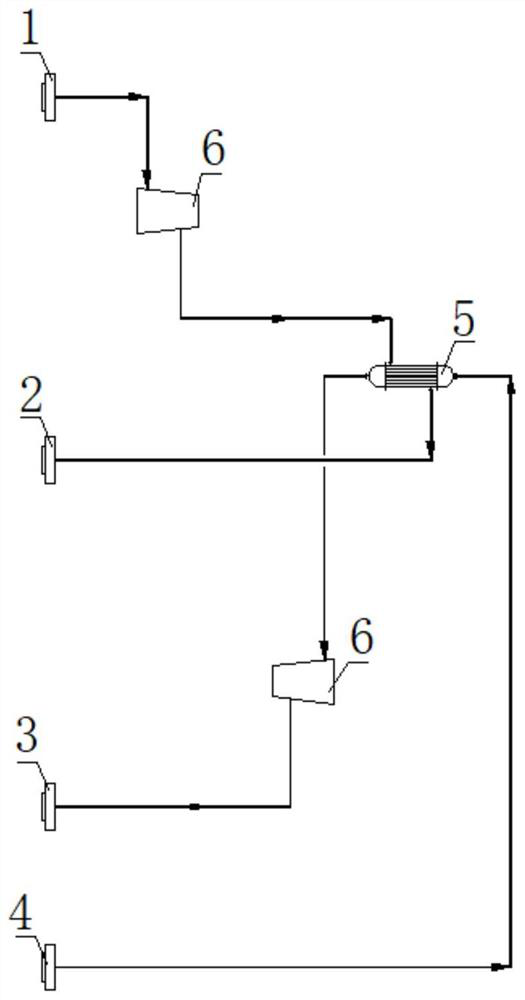

[0044] see Figure 5 In this embodiment, on the basis of the comparative example, an external heat pump system is installed outside the process device. In this embodiment, the process stream is refined methanol, the heat pump working fluid is water, and the booster equipment uses a compressor.

[0045] From the pipeline between the top of the atmospheric column 1-3 and the atmospheric column condenser 1-16, the refined methanol vapor is drawn out through the pipeline, and connected to the external heat pump system through the first process stream inlet 2-5. The inlet 2-5 of a process stream is connected with the first heat pump compressor 2-1, and the refined methanol vapor enters the first partition heat exchanger 2-2 after being compressed and boosted by the first heat pump compressor 2-1, and is mixed with liquid water Carry out heat exchange, transfer heat energy to water and return to the process device from the first process stream outlet 2-6, and enter the original subs...

Embodiment 2

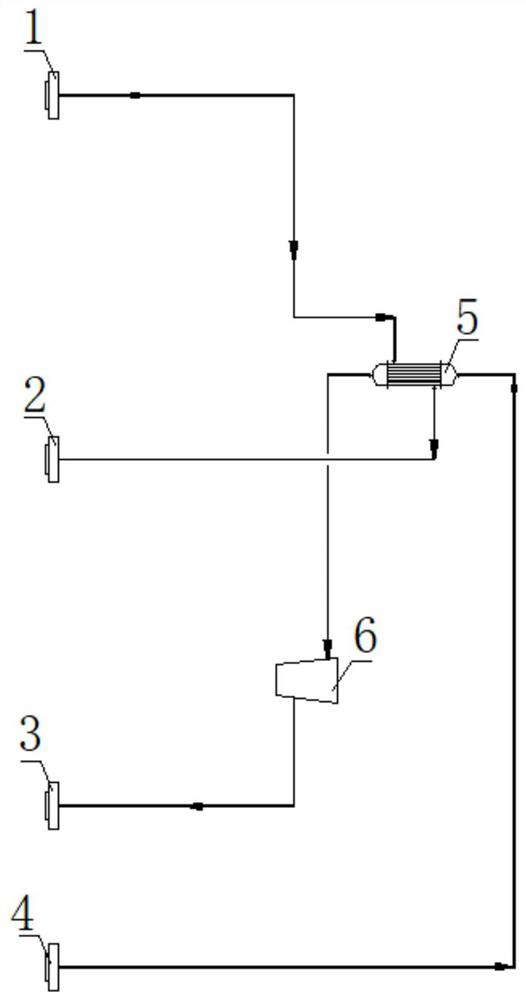

[0048] see Image 6 , this embodiment is further optimized on the basis of Embodiment 1, the difference is that: the external heat pump system has increased the second partition heat exchanger 2-3, the second process stream inlet 2-7, the second process stream Outlet 2-8; wherein, the first partition heat exchanger 2-2 is connected in parallel with the second partition heat exchanger 2-3, and the heat pump working fluid inlet 4 is connected with the first partition heat exchanger 2-2 and the second partition respectively. The partition heat exchanger 2-3 is connected, and the liquid water introduced from the heat pump working fluid inlet 4 performs heat exchange in the first partition heat exchanger 2-2 and the second partition heat exchanger 2-3 respectively, and is transformed into Water vapor, the two streams of water vapor merge and enter the second heat pump compressor 2-4 for compression and boosting, and then transported to the process device through the heat pump worki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com