UV-cured ultrasonic spraying hardening liquid and preparation method thereof

A hardening liquid and ultrasonic technology, applied in the field of hardening liquid, can solve the problems of low VOC emission, oily board area and thick edges, large VOC emission, etc., achieve good wear resistance, moderate drying speed, and reduce VOC The effect of the emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

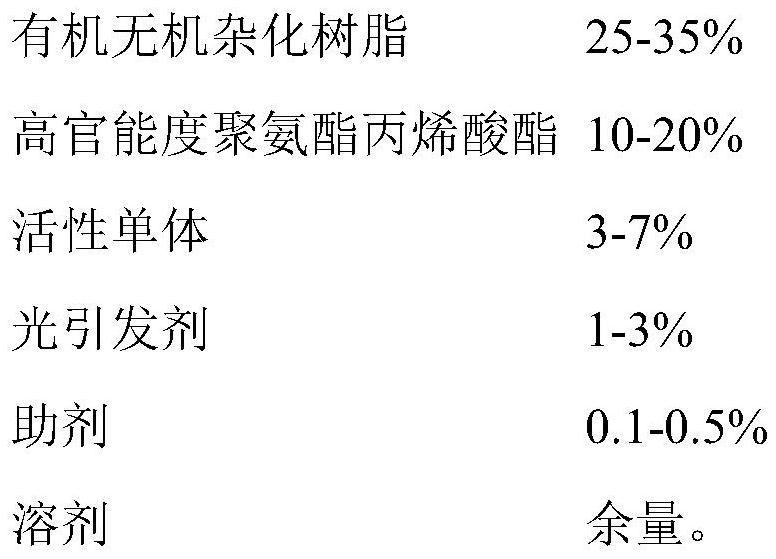

Method used

Image

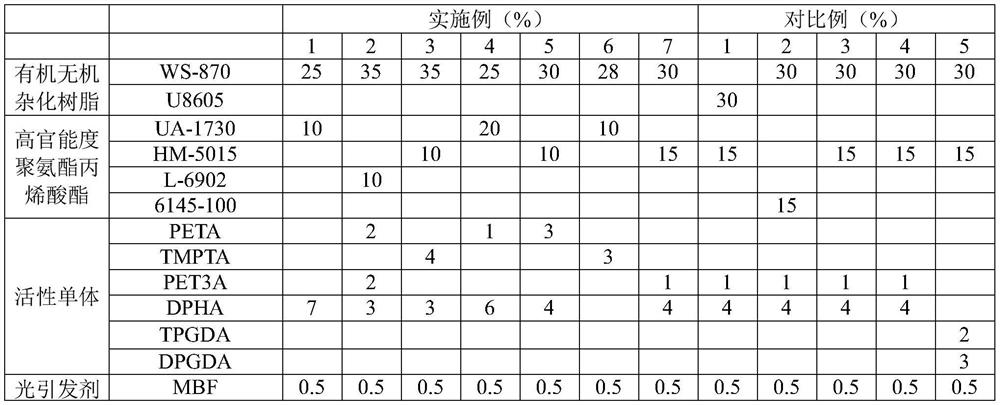

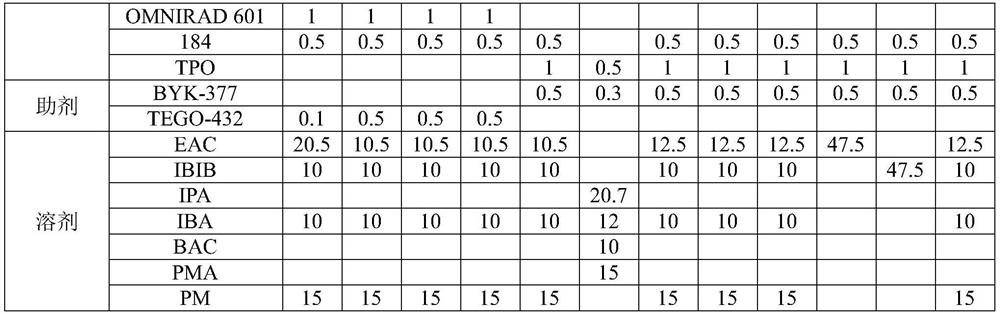

Examples

preparation example Construction

[0025] Preparation of organic-inorganic hybrid resin:

[0026] (1) Add 25kg of ZS-30 silica sol into the reaction kettle, stir and heat up to 60°C, and drop in 25kg of 3-(methacryloyloxy)propyltrimethoxysilane at a stirring speed of 400r / min, Insulated for 1h to prepare modified silica sol liquid;

[0027] (2) Add 10kg of pentaerythritol triacrylate (PETA) and 40kg of 6145-100 to the reaction kettle, stir and heat up to 60°C, and add the modified silica sol prepared in step (1) at a stirring speed of 600r / min Liquid, heat preservation for 1h to obtain organic-inorganic hybrid resin.

[0028] The preparation method of hardening liquid is: under the environment of using yellow light and completely cutting off ultraviolet light, mix the active monomer, photoinitiator and solvent, stir at the speed of 200r / min until dissolved, and add organic and inorganic impurities in sequence after dissolution. The resin, high-functionality urethane acrylate and additives are stirred at a spe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com