Method for preparing FeV50 alloy by using waste iron materials obtained through extraction of vanadium from vanadium slag

A technology of iron materials and vanadium slag, which is applied in the field of metallurgy, can solve the problems of reducing the amount of waste generated in the production line, reducing the production cost of vanadium-ferroalloy, and poor quality of vanadium-ferroalloy, and achieves the effect of qualified composition, good quality and efficient utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

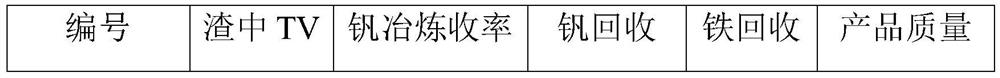

Embodiment 1

[0057] Vanadium pentoxide (TV is 55.0% by weight), vanadium trioxide (TV is 64.0% by weight), aluminum particles (aluminum particle purity is 99.0% by weight, particle size is 0.1cm, the actual addition amount of aluminum particles is theoretical addition 1.0 times of the amount), vanadium slag extracting vanadium waste iron material (vanadium slag extracting vanadium waste iron material is coarse vanadium slag ball mill iron grain, the mass ratio of metallic state Fe and oxidized state Fe in vanadium slag extracting vanadium waste iron material is 4: 1) mix uniformly with lime (the content of CaO in the lime is 85% by weight, and the content of metal impurities is 1% by weight) to obtain the iron-vanadium smelting mixture, and then evenly load the iron-vanadium smelting mixture into the smelting electric furnace for smelting, The electrode is lowered to contact with the material, and the arc is energized to trigger the reaction, and the ignition smelting is carried out (the sm...

Embodiment 2

[0062] Vanadium pentoxide (TV is 55.5% by weight), vanadium trioxide (TV is 66.0% by weight), aluminum particles (aluminum particle purity is 99.5% by weight, particle size is 1cm, the actual addition amount of aluminum particles is the theoretical addition amount 1.1 times of that), vanadium slag extracting vanadium waste iron material (vanadium slag extracting vanadium waste iron material is fine vanadium slag winnowing magnetic matter, the mass ratio of metallic state Fe and oxidized state Fe in vanadium slag extracting vanadium waste iron material is 6: 1), iron filings (the purity of iron filings is 99.5% by weight, and the surface area of iron filings is 5cm 2 ) and lime (the content of CaO in the lime is 90.0% by weight, and the content of metal impurities is 0.5% by weight) are mixed evenly to obtain the iron-vanadium smelting mixture, and then the iron-vanadium smelting mixture is evenly loaded into the smelting electric furnace for smelting, and the The electrode i...

Embodiment 3

[0067] Vanadium pentoxide (TV is 55.0% by weight), vanadium trioxide (TV is 64.0% by weight), aluminum particles (the purity of aluminum particles is 99.0% by weight, and the particle size is 0.5cm. The actual addition amount of aluminum particles is theoretical addition amount of 1.0 times), vanadium slag extracting vanadium waste iron material (vanadium slag extracting vanadium waste iron material is leaching tailings iron enrichment material, the mass ratio of metallic state Fe and oxidized state Fe in vanadium slag extracting vanadium waste iron material is 10 1) mix uniformly with lime (the content of CaO in the lime is 85% by weight, and the content of metal impurities is 0.6% by weight) to obtain the iron-vanadium smelting mixture, and then put the iron-vanadium smelting mixture evenly into the smelting electric furnace for smelting , the electrode is lowered to contact with the material, and the arc is energized to trigger the reaction, and the ignition smelting is carr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com