Preparation process of supercapacitor electrode

A technology of supercapacitor and preparation process, applied in the manufacture of hybrid/electric double-layer capacitors, etc., can solve the problems of low mechanical strength, poor cycle performance and low power density of dry carbon film, and achieve convenient control, enhanced stability, The effect of high power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

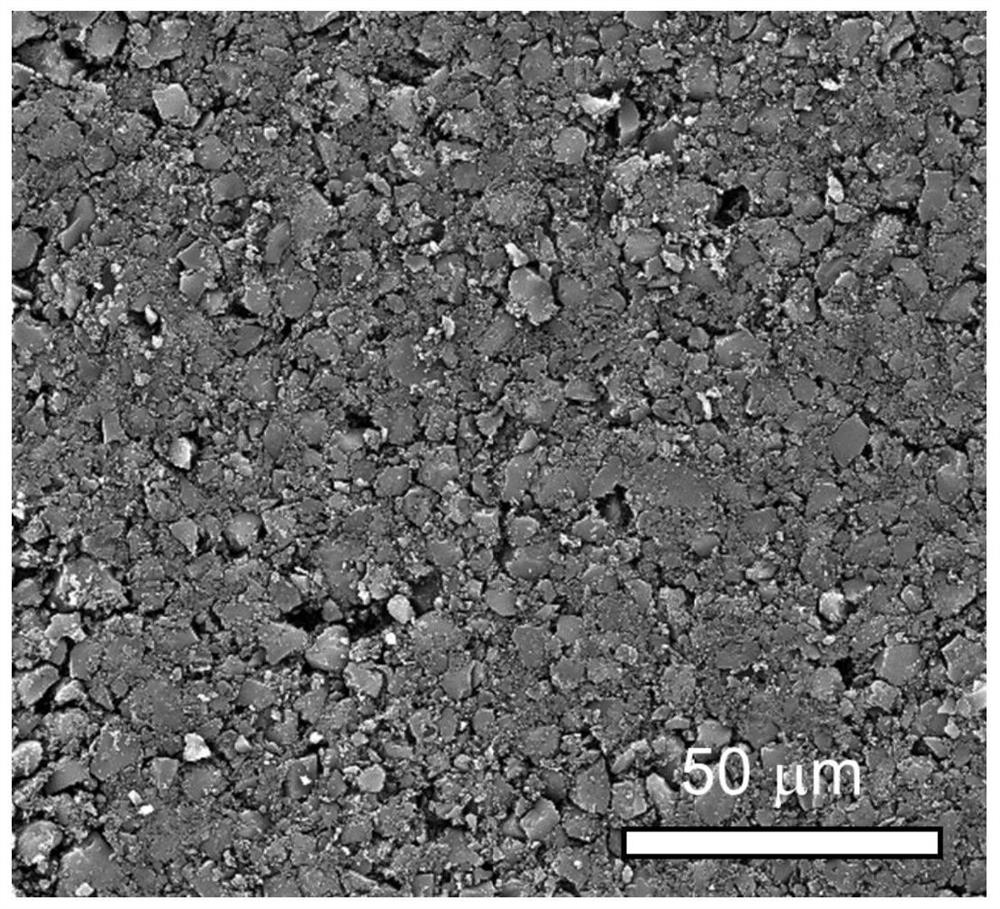

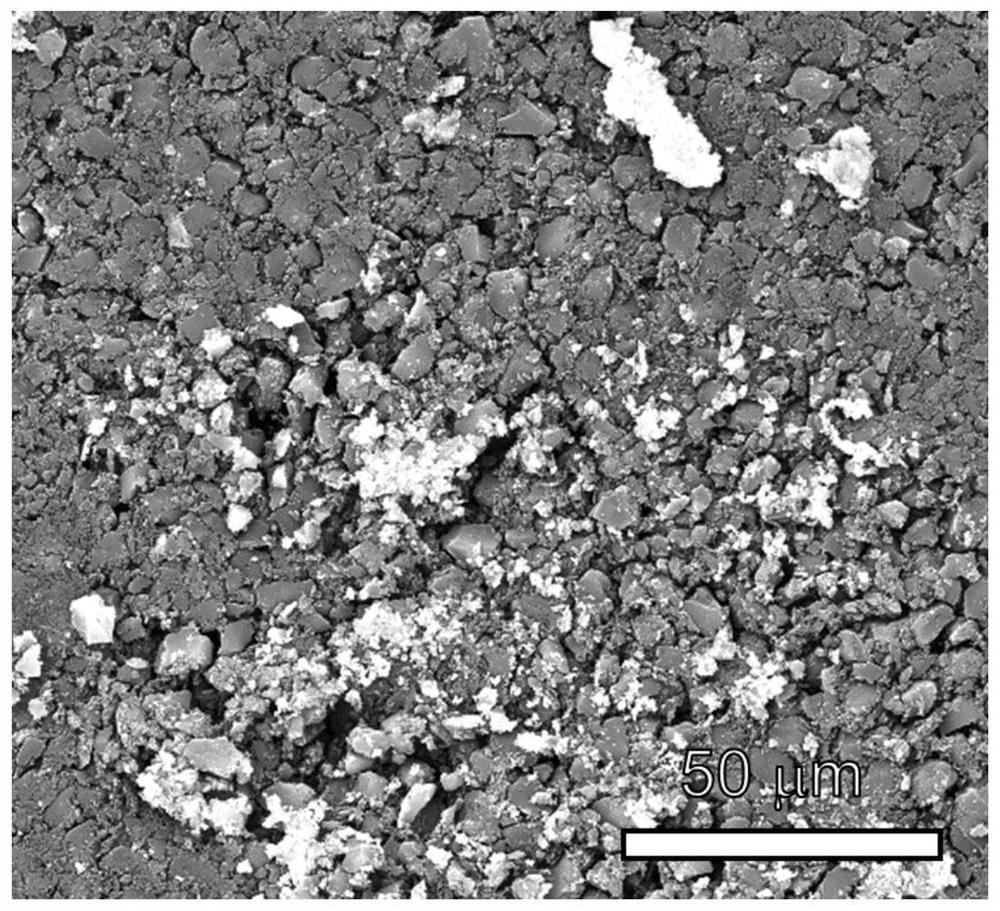

Image

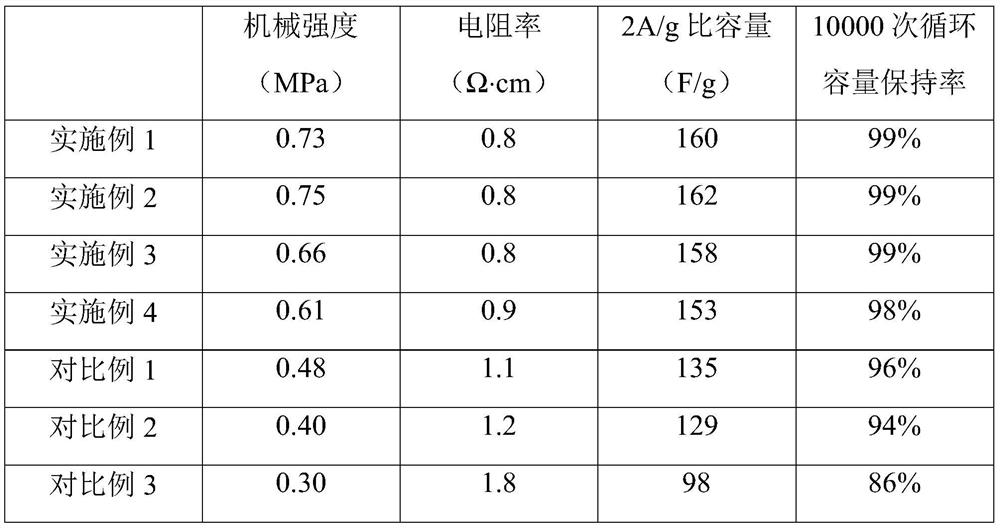

Examples

Embodiment 1

[0028] A preparation process for a supercapacitor electrode, specifically comprising the following steps:

[0029] Step a, take by weight 90 parts of activated carbon, 5 parts of polytetrafluoroethylene and 5 parts of conductive carbon black and mix them in a mixer at a stirring speed of 60r / min to obtain active powder. The temperature of the above mixing is 15 ℃;

[0030] Step b, mixing the above-mentioned active powder in a high energy ball mill at 200r / min for 3h to obtain a solid mixture;

[0031] Step c, spraying a layer of conductive adhesive with a thickness of 3 μm on the surface of the aluminum foil to form a conductive coating; rolling the above-mentioned solid mixture vertically and horizontally at 90° C. to obtain a dry carbon film, and pasting the conductive coating, After curing at 120°C for 5h, supercapacitor electrodes were obtained.

Embodiment 2

[0033] A preparation process for a supercapacitor electrode, specifically comprising the following steps:

[0034] Step a. Weigh 82 parts of activated carbon, 8 parts of polytetrafluoroethylene and 10 parts of conductive agent in a blender at a stirring speed of 120r / min to obtain active powder. The temperature of the above mixing is 10°C , the above-mentioned conductive agent is carbon nanotubes and graphene with a mass ratio of 1:2;

[0035] Step b, mixing the above-mentioned active powder in a high-energy ball mill at 400r / min for 1.5h to obtain a solid mixture;

[0036] Step c, spraying a layer of conductive adhesive with a thickness of 3 μm on the surface of the aluminum foil to form a conductive coating; rolling the above-mentioned solid mixture vertically and horizontally at 90° C. to obtain a dry carbon film, and pasting the conductive coating, After curing at 90°C for 6h, supercapacitor electrodes were obtained.

Embodiment 3

[0038] A preparation process for a supercapacitor electrode, specifically comprising the following steps:

[0039] Step a, weigh 88 parts of activated carbon, 4 parts of polytetrafluoroethylene and 8 parts of graphene in a mixer at a stirring speed of 150r / min to obtain active powder by weight, and the temperature of the above mixing is 5°C ;

[0040] Step b, mixing the above-mentioned active powder in a high-energy ball mill at 400r / min for 2h to obtain a solid mixture;

[0041] Step c, spraying a layer of conductive adhesive with a thickness of 3 μm on the surface of the aluminum foil to form a conductive coating; rolling the above solid mixture vertically and horizontally at 30°C to obtain a dry carbon film, and pasting the conductive coating, After curing at 150°C for 4h, supercapacitor electrodes were obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com