Electronic-grade sulfuric acid preparation device and preparation method thereof

A preparation device and electronic-grade technology, applied in electronic-grade sulfuric acid preparation device and its preparation field, can solve the problems of poor treatment effect and low efficiency of waste gas and acid mist

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

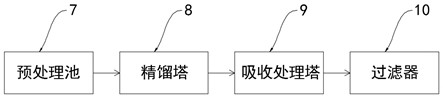

[0040] Electronic grade sulfuric acid preparation device, such as Figure 1-8 As shown, including:

[0041] The pretreatment pool 7, the pretreatment pool is contained in the pretreatment cell, the strong oxidant comprising potassium permanganate and potassium having a red chromate for reducing impurities in the raw material of oxidation;

[0042] The rectification column 8, the rectification tower interior temperature is 185-195 ° C, the pressure is 1.45-2.23 kPa, and the sulfate impurities produced by oxidation in the pretreatment cell, resulting in high purity sulfuric acid;

[0043] The absorption treatment tower 9 is provided with an alkaline solution in the absorbing treatment tower for absorbing the acidic exhaust gas generated in the distillation column;

[0044] Filter 10, the filter is provided with a microporous filter film, which can remove fine solid particulate impurities in high purity sulfuric acid.

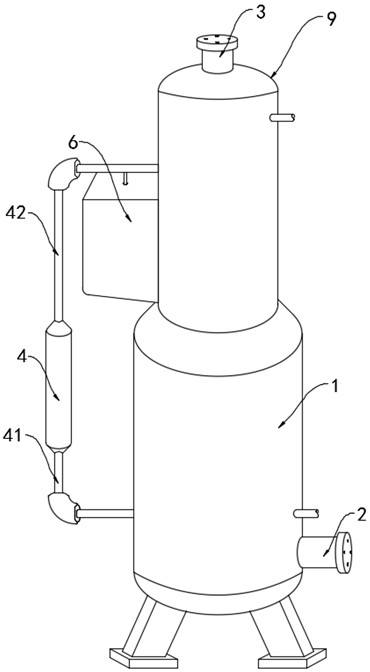

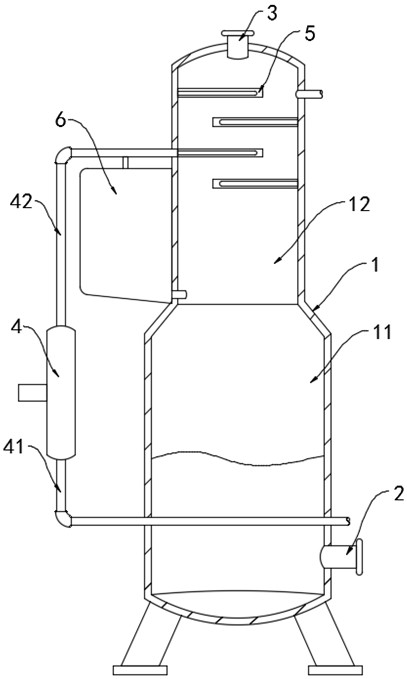

[0045] Further, the absorption treatment tower 9 includes a cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com