Preparation method of efficient two-dimensional nano material filtering film

A technology of two-dimensional nanomaterials and thin films, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of high cost, long functionalization time and low efficiency of two-dimensional nanomaterials, and achieve simple equipment. , The film thickness is easy to control and the effect is less time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

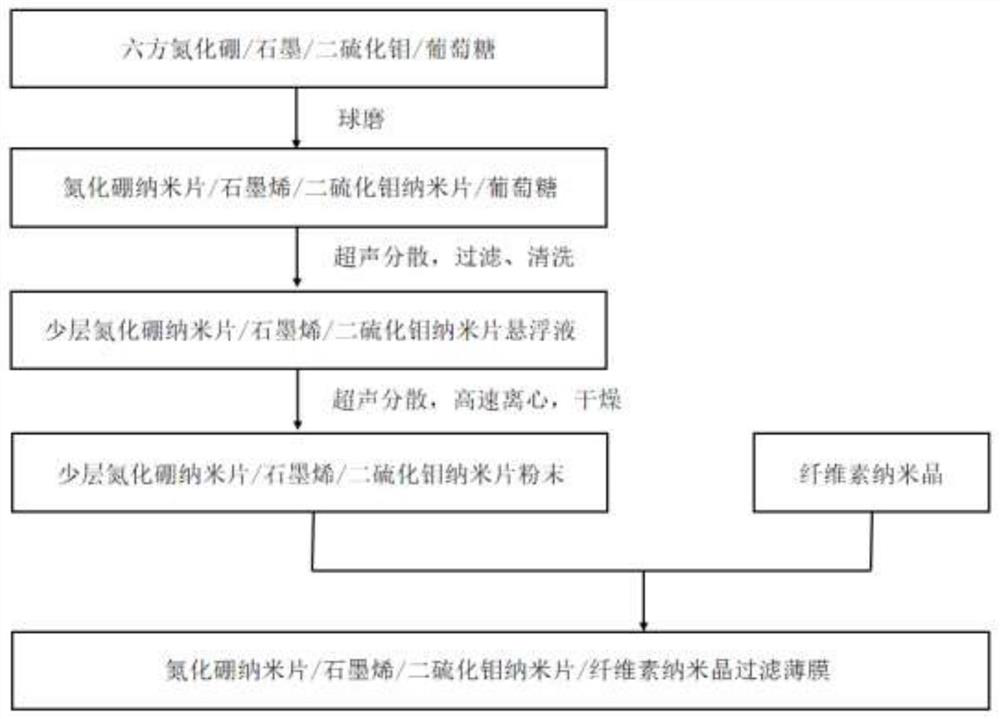

[0020] The invention is a method for preparing a high-efficiency two-dimensional nanomaterial filter film, comprising the following steps:

[0021] S1. Put hexagonal boron nitride, graphite, molybdenum disulfide and corundum grinding balls into the corundum ball milling tank. The corundum grinding balls are set to two types, including 150g of corundum grinding balls with a diameter of 10mm and 15g of corundum grinding balls with a diameter of 1mm. , the total weight of hexagonal boron nitride, graphite and molybdenum disulfide is 3g, the average particle size is 5-9μm, and the mass ratio is 1:1:1;

[0022] S2. The corundum ball milling tank is rotated and ball milled under the protection of argon to obtain a mixed powder of boron nitride nanosheets, graphene, molybdenum disulfide nanosheets and glucose. The ball milling speed is 300r / min, and the ball milling time is 6h;

[0023] S3. Weigh 2 g of the mixed powder obtained by ball milling in step S2, put it into 1000 ml of deio...

Embodiment 2

[0030] The invention is a method for preparing a high-efficiency two-dimensional nanomaterial filter film, comprising the following steps:

[0031] S1. Put hexagonal boron nitride, graphite, molybdenum disulfide and corundum grinding balls into the corundum ball milling tank. The corundum grinding balls are set to two types, including 200g of corundum grinding balls with a diameter of 10mm and 20g of corundum grinding balls with a diameter of 1mm. , the total weight of hexagonal boron nitride, graphite and molybdenum disulfide is 4g, the average particle size is 3-8μm, and the mass ratio is 1:1:1;

[0032] S2. The corundum ball milling tank is rotated and milled under the protection of argon to obtain a mixed powder of boron nitride nanosheets, graphene, molybdenum disulfide nanosheets and glucose. The ball milling speed is 200r / min, and the ball milling time is 8h;

[0033] S3. Weigh 1 g of the mixed powder obtained by ball milling in step S2, put it into 800 ml of deionized ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com