Solvent-free release silicone oil suitable for PET film and preparation method of solvent-free release silicone oil

A solvent-free, release technology, applied in the direction of film/sheet adhesives, adhesives, film/sheet release liners, etc., can solve the problems of non-release, release silicone oil coating, release difficulties, etc. , to achieve the effect of increasing adhesion, reducing peeling force and good curing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

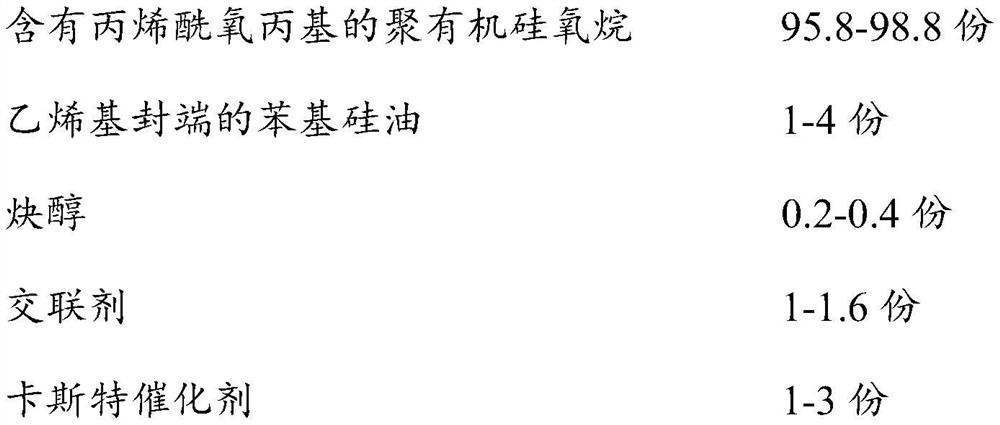

[0035] 97.6 parts of polyorganosiloxane containing acryloyloxypropyl group, 2 parts of vinyl-terminated phenyl silicone oil, 0.4 part of acetylenic alcohol, 1.4 parts of crosslinking agent, and 1.5 parts of Castel catalyst.

[0036] Among them, polyorganosiloxane containing acryloxypropyl group, vinyl-terminated phenyl silicone oil, and acetylenic alcohol are used as the main agent of the release silicone oil.

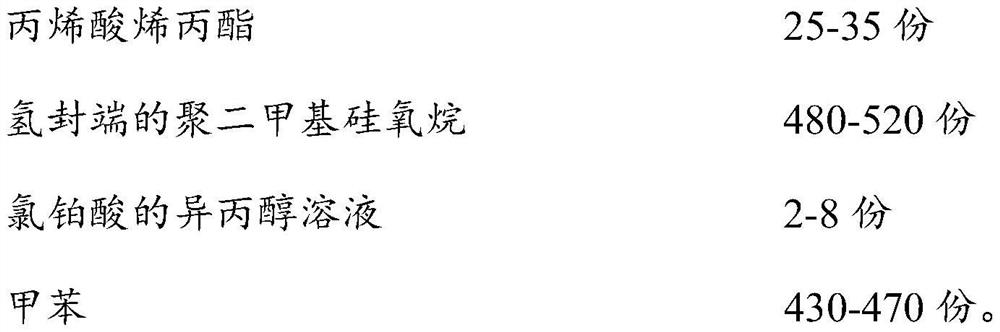

[0037] Among them, in the polyorganosiloxane containing acryloyloxypropyl group, the synthetic formula has the following components in terms of parts by weight: 30 parts of allyl acrylate, 500 parts of hydrogen-terminated polydimethylsiloxane, chlorine 5 parts of isopropanol solution of platinum acid, 450 parts of toluene.

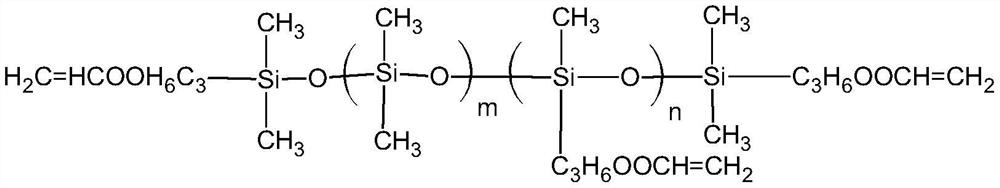

[0038] Among them, the polyorganosiloxane containing acryloyloxypropyl has a viscosity of 480mPa·s, and its structural formula is:

[0039]

[0040] Wherein, m=50-500, n=0-10.

[0041] In this embodiment, the polyorganosiloxane containing acry...

Embodiment 2

[0059] The difference between this embodiment and embodiment 1 is:

[0060] 95.8 parts of polyorganosiloxane containing acryloyloxypropyl group, 4 parts of vinyl-terminated phenyl silicone oil, 0.2 part of acetylenic alcohol, 1 part of crosslinking agent, and 1 part of Castel catalyst.

[0061] Among them, in the polyorganosiloxane containing acryloyloxypropyl group, the synthetic material has the following components in terms of parts by weight: 25 parts of allyl acrylate, 480 parts of hydrogen-terminated polydimethylsiloxane, chlorine 2 parts of isopropanol solution of platinum acid, 430 parts of toluene.

[0062] Wherein, the viscosity of polyorganosiloxane containing acryloxypropyl group is 300mPa·s, further, the structural formula of polyorganosiloxane containing acryloxypropyl group is:

[0063]

[0064] Among them, the viscosity of hydrogen-terminated polydimethylsiloxane is 20mPa·s,

[0065] Wherein, the concentration of elemental platinum in the isopropanol solut...

Embodiment 3

[0071] The difference between this embodiment and embodiment 1 is:

[0072] 98.8 parts of polyorganosiloxane containing acryloyloxypropyl group, 1 part of vinyl-terminated phenyl silicone oil, 0.2 part of acetylenic alcohol, 1.6 parts of crosslinking agent, and 3 parts of Castel catalyst.

[0073] Among them, in the polyorganosiloxane containing acryloyloxypropyl group, the synthetic material contains the following components in parts by weight: 35 parts of allyl acrylate, 520 parts of hydrogen-terminated polydimethylsiloxane, chlorine 8 parts of isopropanol solution of platinum acid, 470 parts of toluene.

[0074] Wherein, the polyorganosiloxane containing acryloxypropyl group has a viscosity of 600mPa·s, and further, the structural formula of the polyorganosiloxane containing acryloxypropyl group is:

[0075]

[0076] Among them, the viscosity of hydrogen-terminated polydimethylsiloxane is 150mPa·s,

[0077] Wherein, the concentration of elemental platinum in the isopro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com