Preparation method of metal protective film with self-repairing function and super-amphiphobic function

A super-amphiphobic, protective film technology, used in anti-corrosion coatings, devices for coating liquid on surfaces, coatings, etc., can solve the problem of single function of the film layer, and achieve simple process, convenient operation, and excellent self-healing function. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

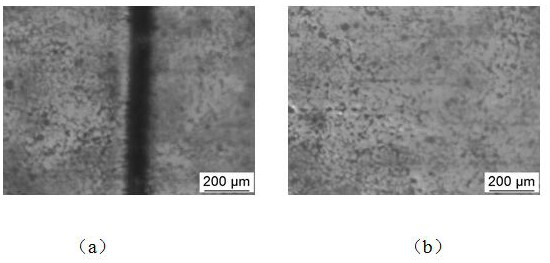

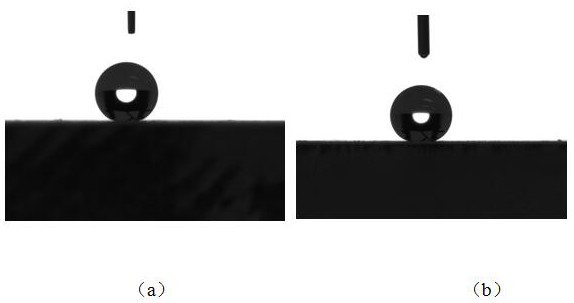

Image

Examples

Embodiment 1

[0023] A method for preparing a protective film on the surface of AZ31 magnesium alloy with both self-repairing function and super-amphiphobic function, which specifically includes the following steps:

[0024] ① Dipping and pulling film formation: Use a dipping and pulling machine to perform dipping and pulling to form a film. Completely immerse the cleaned magnesium alloy workpiece in #1 immersion solution, pure water, #2 immersion solution, pure water, #3 immersion solution, and pure water at 60°C for 20 minutes each, and the pulling speed is 0.1mm / s respectively . The speed is pulled out.

[0025] The #1 immersion solution is uniformly mixed with aluminum phosphate solution and commercially available polytetrafluoroethylene emulsion in a volume ratio of 1:3; wherein the configuration process of aluminum phosphate solution is (same as other embodiments): Al(OH) 3 powder and a concentration of 60 wt% H 3 PO 4 Mix at a molar ratio of 3:1, mix at a molar ratio of 3:1, and ...

Embodiment 2、3 and 4

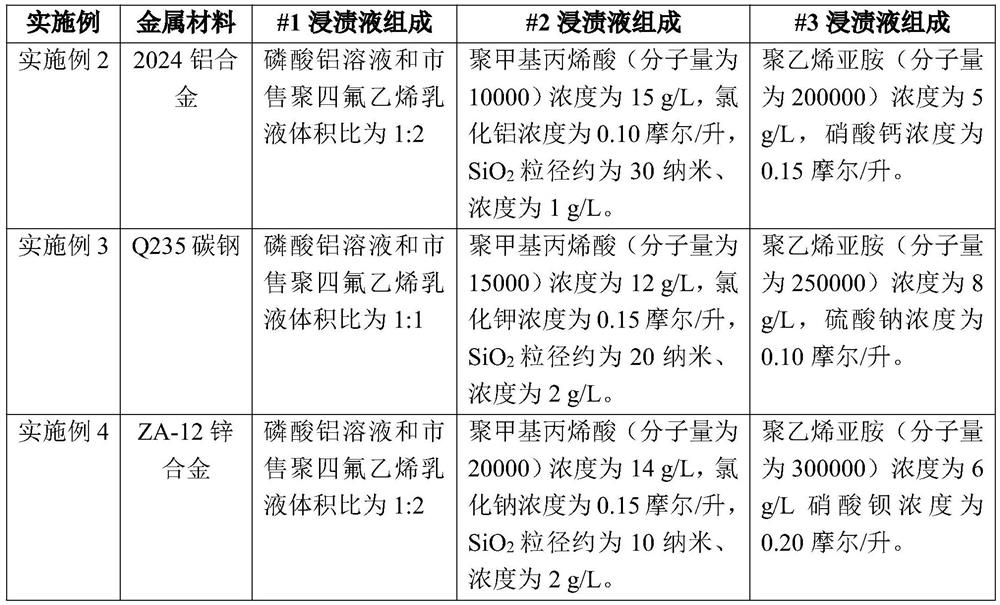

[0035] The preparation steps, performance and function test method of the protective film are the same as in Example 1, but the metal materials used as the protection object are different (see Table 1), the composition of the impregnation solution is different (see Table 1), and the preparation conditions are different (see Table 2) , performance and functional test results vary (see Table 3).

[0036]Table 1 metal material used in each embodiment and impregnating solution composition

[0037]

[0038] The film layer preparation conditions corresponding to each embodiment of table 2

[0039]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com