Composite material plate shell with thickness gradual change area and forming device and method of composite material plate shell

A composite material plate and molding device technology, which is applied in transportation and packaging, space navigation equipment, space navigation aircraft, etc. The effect of improving the production quality and improving the emission effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

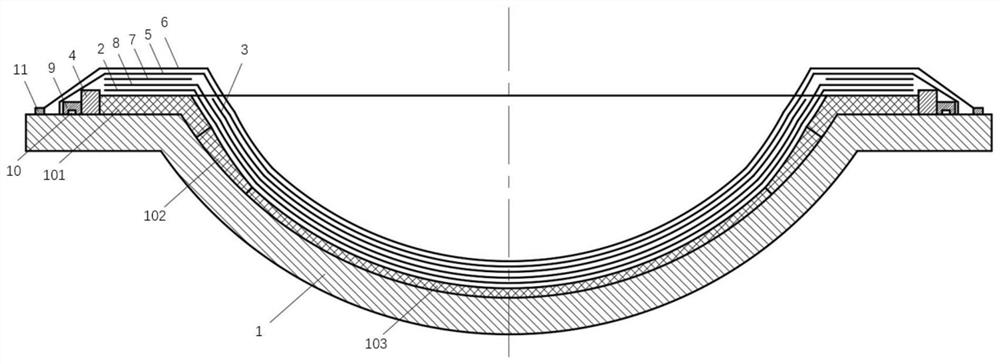

Embodiment 1

[0036] The invention provides a molding device for a composite material shell with a thickness gradient zone, such as Figure 1-2 As shown, it is especially suitable for forming devices with single-curved or double-curved plate and shell structures with flange edges, including forming mold 1, breathable release cloth 2, porous isolation film 3, surrounding strip 4, air felt 5 And vacuum film 6. The forming mold 1 is used as a basic load-bearing part, and the composite material prepreg forming the plate shell is laid on the inner surface of the forming mold 1 to form a composite material layer. The shape of the molding die 1 is designed according to the shape of the plate and shell to be produced, for example, the typical structure includes a hemispherical shape with an outer platform, a truncated cone shape, and the like. The surrounding bar 4 is movably installed on the outer edge platform of the inner surface of the forming mold 1, and one side of the surrounding bar 4 is u...

Embodiment 2

[0040]This embodiment 2 is formed on the basis of embodiment 1. Through the design of the pressure stabilizing structural parts and the adsorption structural parts, the pressure area applied to the composite material layer during the manufacturing process of the plate and shell is made uniform, and the loss of the composite material layer is ensured. Within the control range, the manufacturing quality of the plate shell is improved.

[0041] Such as Figure 1-2 As shown, a rubber-absorbing felt 8 with adsorption function is set in the composite material plate and shell forming device, and the rubber-absorbing felt 8 is arranged between the air-permeable release cloth 2 and the porous isolation film 3 for adsorption on the pressurized and heated composite Composite material spilled during material layers. By designing the adsorption capacity of the rubber-absorbing felt 8, that is, by designing the rated adsorption capacity of the rubber-absorbing felt 8, it is ensured that th...

Embodiment 3

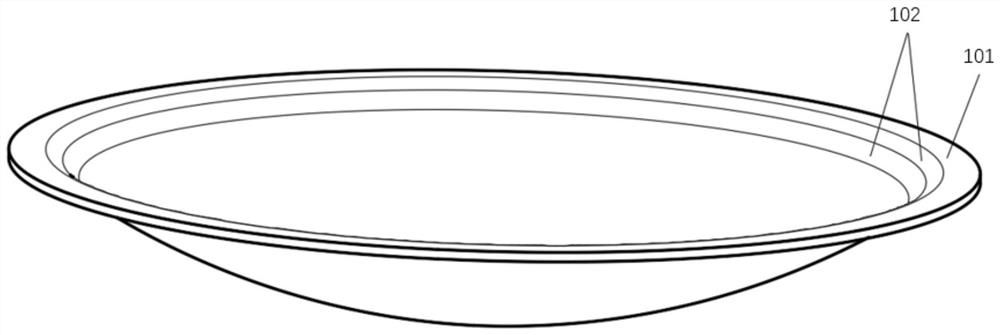

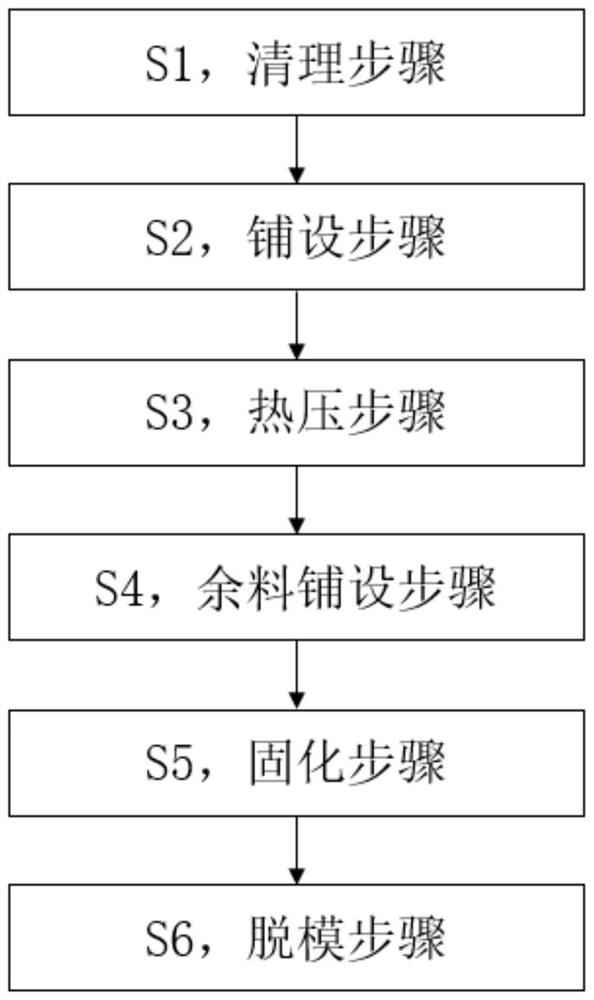

[0044] This embodiment 3 is a forming method for a composite material plate and shell with a thickness gradient zone formed by using the molding device for a composite material plate and shell with a thickness gradient zone in embodiment 1 or embodiment 2, such as Figure 1-3 As shown, taking a composite material panel shell with large wall thickness, including a hyperboloid surface, and variable thickness as an example, the main part of the composite material panel shell 100 to be manufactured is spherical (double curvature surface), and the outer edge of the main body is set Plane flange, the flange and the adjacent part of the spherical surface are the thickened area 101, and its main part is called the flat thick area 103, and the distance from the thickened area 101 to the flat thick area 103 whose thickness gradually becomes thinner is recorded as the thickness gradient area 102. The thickening zone 101 has a wall thickness of 12 mm, the flat thickness zone has a wall th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com