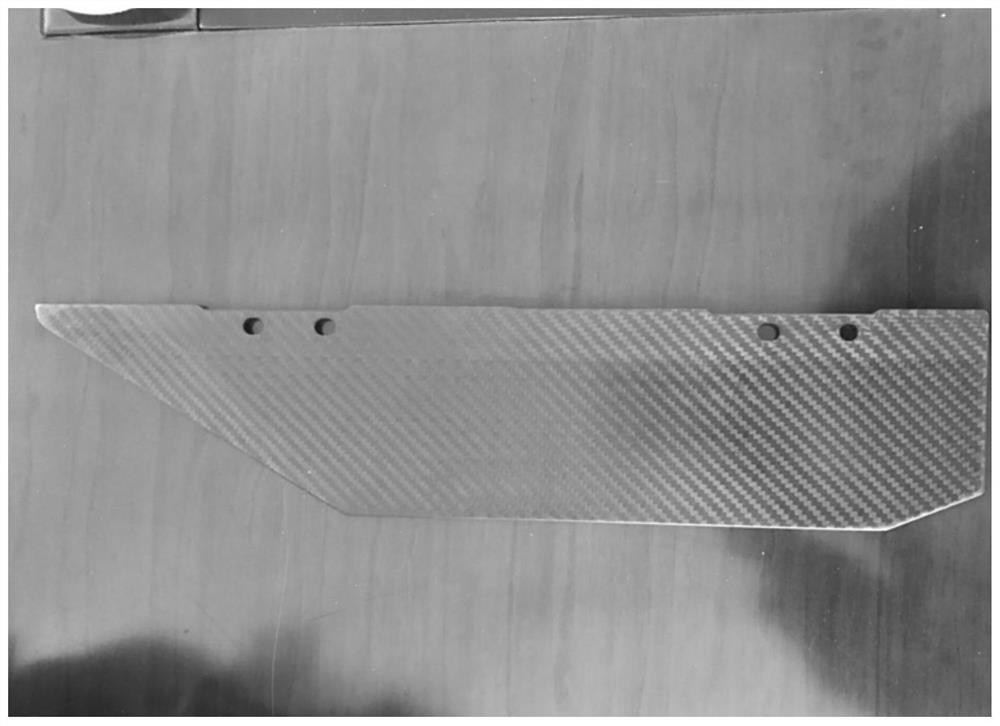

A kind of carbon fiber reinforced composite material wing and preparation method thereof

A reinforced composite material and carbon fiber technology, which is applied to other household appliances, household appliances, household components, etc., to achieve the effects of easy control of parameters, high strength, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

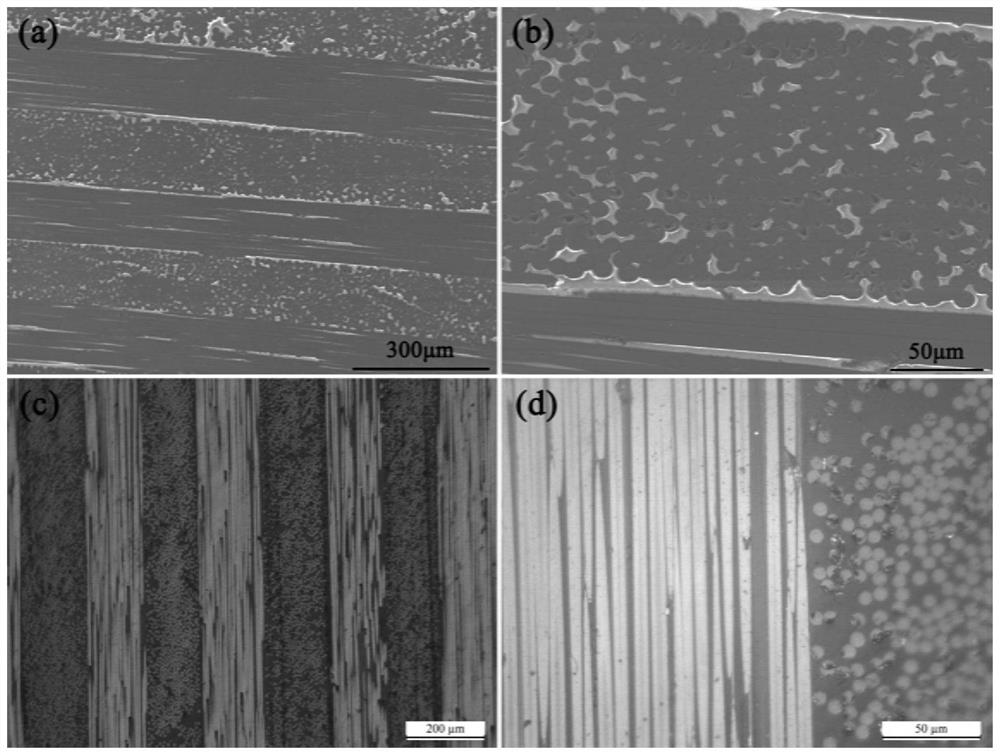

[0042] (1) Impregnating 12K T700 carbon fiber unidirectional cloth with modified phenolic resin to obtain carbon fiber unidirectional cloth prepreg, wherein in the carbon fiber unidirectional cloth prepreg, the mass fraction of modified phenolic resin is 40%;

[0043] The 3K T300 carbon fiber twill fabric is impregnated with modified phenolic resin to obtain carbon fiber twill fabric prepreg, wherein the mass fraction of modified phenolic resin in the carbon fiber twill fabric is 40%.

[0044] (2) Cut the 12K T700 carbon fiber unidirectional cloth prepreg into small pieces with different widths, lengths and plane projection shapes of the wings. Then, the prepreg carbon fiber unidirectional cloth pieces are stacked at an angle that the fiber directions are perpendicular to each other, and the number of layers is 55 to obtain a carbon fiber unidirectional cloth prepreg block.

[0045] (3) Then, two layers of 3K T300 carbon fiber twill prepreg were coated on the upper and lower s...

Embodiment 2

[0051] (1) Impregnating 12K T700 carbon fiber unidirectional cloth with modified phenolic resin to obtain carbon fiber unidirectional cloth prepreg, wherein in the carbon fiber unidirectional cloth prepreg, the mass fraction of modified phenolic resin is 40%;

[0052] The 3K T300 carbon fiber twill fabric is impregnated with modified phenolic resin to obtain carbon fiber twill fabric prepreg, wherein the mass fraction of modified phenolic resin in the carbon fiber twill fabric is 40%.

[0053] (2) Cut the 12K T700 carbon fiber unidirectional cloth prepreg into small pieces with different widths, lengths and plane projection shapes of the wings. Then, 55 layers of carbon fiber unidirectional cloth prepreg pieces are laminated at an angle of 45° between the fiber directions to obtain a carbon fiber unidirectional cloth prepreg block.

[0054] (3) Then, two layers of 3K T300 carbon fiber twill prepreg were coated on the upper and lower surfaces of the carbon fiber unidirectional ...

Embodiment 3

[0060] (1) Impregnating 12K T700 carbon fiber unidirectional cloth with modified phenolic resin to obtain carbon fiber unidirectional cloth prepreg, wherein the mass fraction of modified phenolic resin in the carbon fiber unidirectional cloth prepreg is 45%;

[0061] The 3K T300 carbon fiber twill fabric is impregnated with modified phenolic resin to obtain carbon fiber twill fabric prepreg, wherein the mass fraction of modified phenolic resin in the carbon fiber twill fabric is 45%.

[0062] (2) Cut the 12K T700 carbon fiber unidirectional cloth prepreg into small pieces with different widths, lengths and plane projection shapes of the wings. Then, the prepreg carbon fiber unidirectional cloth pieces are stacked at an angle that the fiber directions are perpendicular to each other, and the number of layers is 55 to obtain a carbon fiber unidirectional cloth prepreg block.

[0063] (3) Then, two layers of 3K T300 carbon fiber twill prepreg were coated on the upper and lower su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com